Doug, at first I didnt think to much about regen on a wood splitter simply because of the power loss. To give a example of the loss, a 4in bore x 2in rod with a 24in stroke cyl at 3000psi would normally equate to a 20ton log splitter. (I'm rounding numbers here). With regen, that same cyl at same pressure would turn into about a 5ton wood splitter. Even tho the cycle time would be reduced considerablely, the force trade off to me wouldnt be worth the effort.

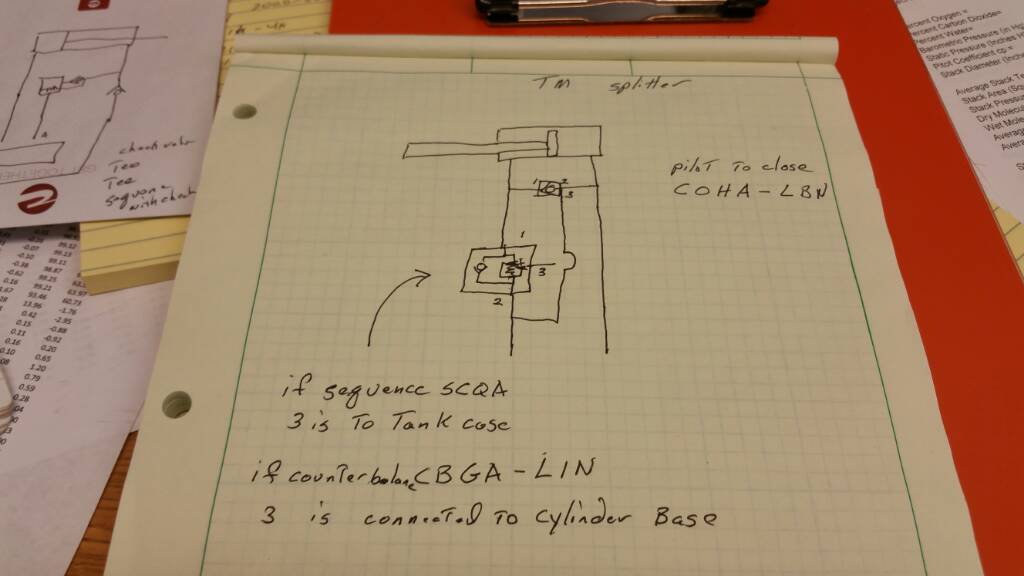

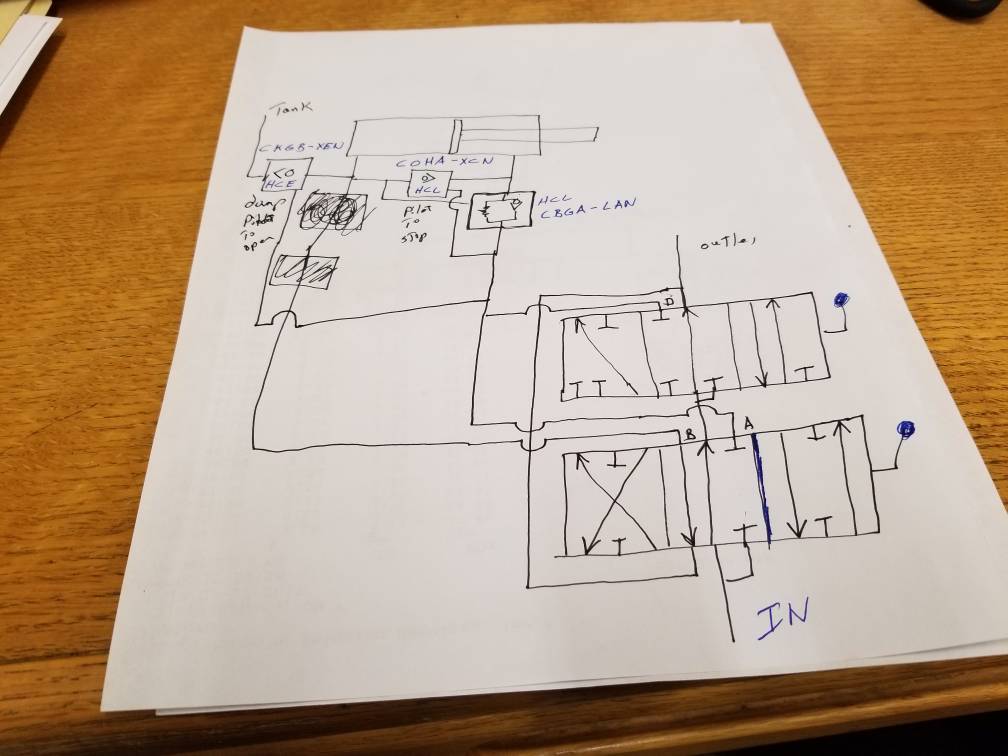

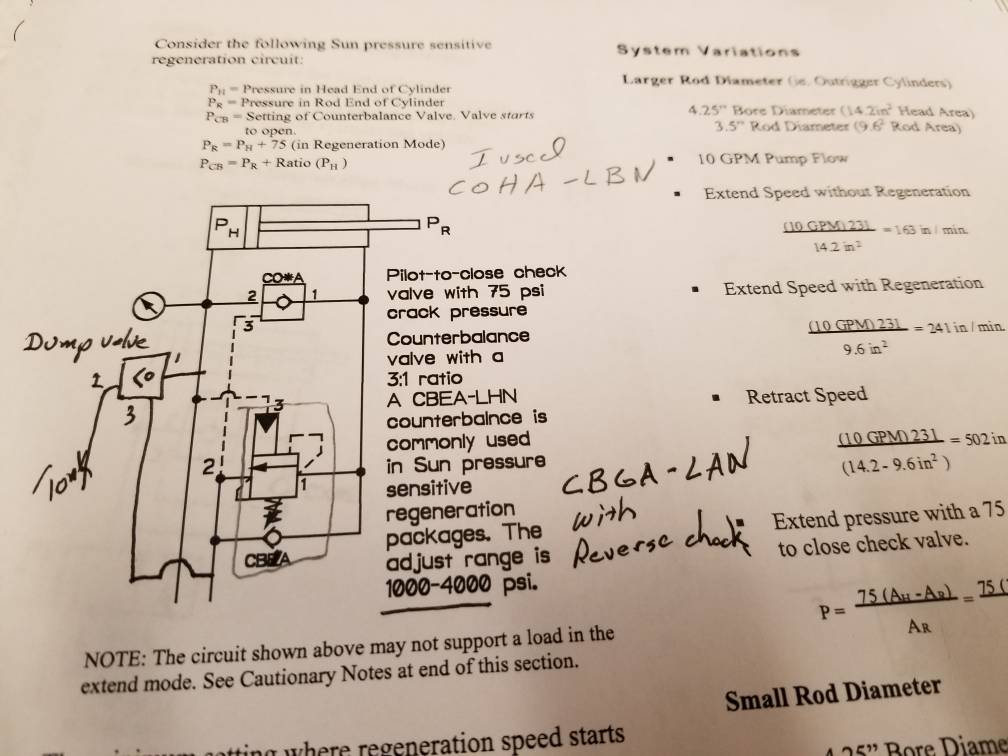

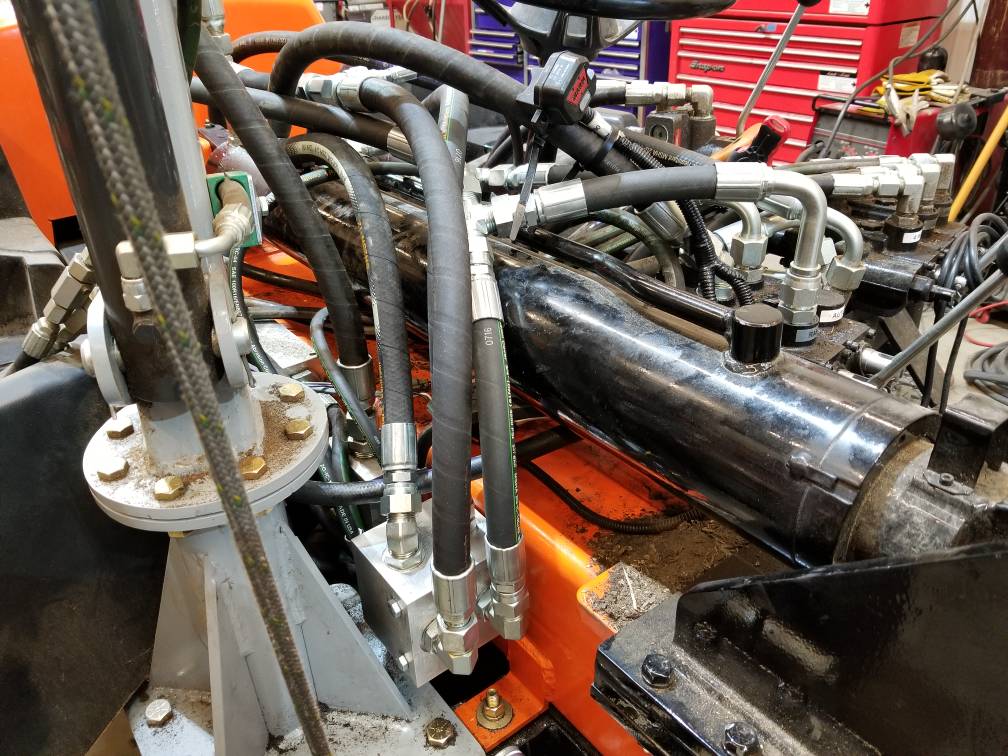

My mind has sort of changed now that I see what you are attempting. Altho your schematic is sort of vague as to exactly what you are plumbing in, I can see the potential. For those that dont know, regen is simply applying pressure to both ends of the cyl at the same time to increase cyl extention speed. The trade off is loss of force, as in my example above. Usually this is done at the control valve and requires human input to take the valve out of regent and place in normal hyd flow to gain back the force. Doug is taking a different approach to sort of automate the processes. By using the counter balance valve, he is reading pressure, presumably at the base end of the cyl, to change the direction of hyd flow and take the circuit out of regen mode and into normal mode. Sort of like your two stage pumps sense pressure and drops from high flow/low pressure to low flow/high pressure.

While I at first passed this off as unnecessary. I dont need that extra half sec of speed I would gain, since I split longer wood than most and I only have a inch or two before the pusher strikes the round to be split. How much time could I really save and its adds another human function to the process. Then I got to thinking, While I only need the speed for the sec it takes to hit the wood, I only need the force for a sec or two to split the wood. Maybe the 5ton would be more than enough to finish pushing the wood thru the wedge. Regen started making more sense. With Dougs proposed setup, the cyl would be in regen until a load is sensed at what ever preset pressure he choose, at which time the valve would shift out of regen into full force splitting mode. As soon as the pressure requirement dropped below the preset level, it would go back into regen and speed up the splitter. That 4in cyl in my example could go from a 13sec cyl time to a 7 or 8 sec cycle time. (@10gpm)

Where I think it would benefit me most would be using the 32in stroke cyls on my wood processor. I wont be splitting a lot of 32in long firewood, so I might be wasting half a stroke on every round. Since I am going to be pumping 75gpm to my cyl, dont know where I am going to find the valves to make it work with regen, but Its something I am now keeping a eye out for.