Mastermind

Work Saw Specialist

Ticks don't come from trees. Google ticks falling out of trees.

I know.......the bastards crawl up my legs and bite me.

I hate em......almost as bad as chiggers. :msp_unsure:

Ticks don't come from trees. Google ticks falling out of trees.

I know.......the bastards crawl up my legs and bite me.

I hate em......almost as bad as chiggers. :msp_unsure:

Operators are standing by. :msp_thumbup:

I remember you didn't like advance timing on a work saw. Does this one need it?

Twins....,Make it triplets Randy, mine should show up Monday.

opcorn:

You make it seem easy and I've got my South Bend lathe all set up. Maybe I should? Maybe I should stick to woodworking!!! :msp_unsure:

And let you do my saws.

Are you using a South Bend for wood?

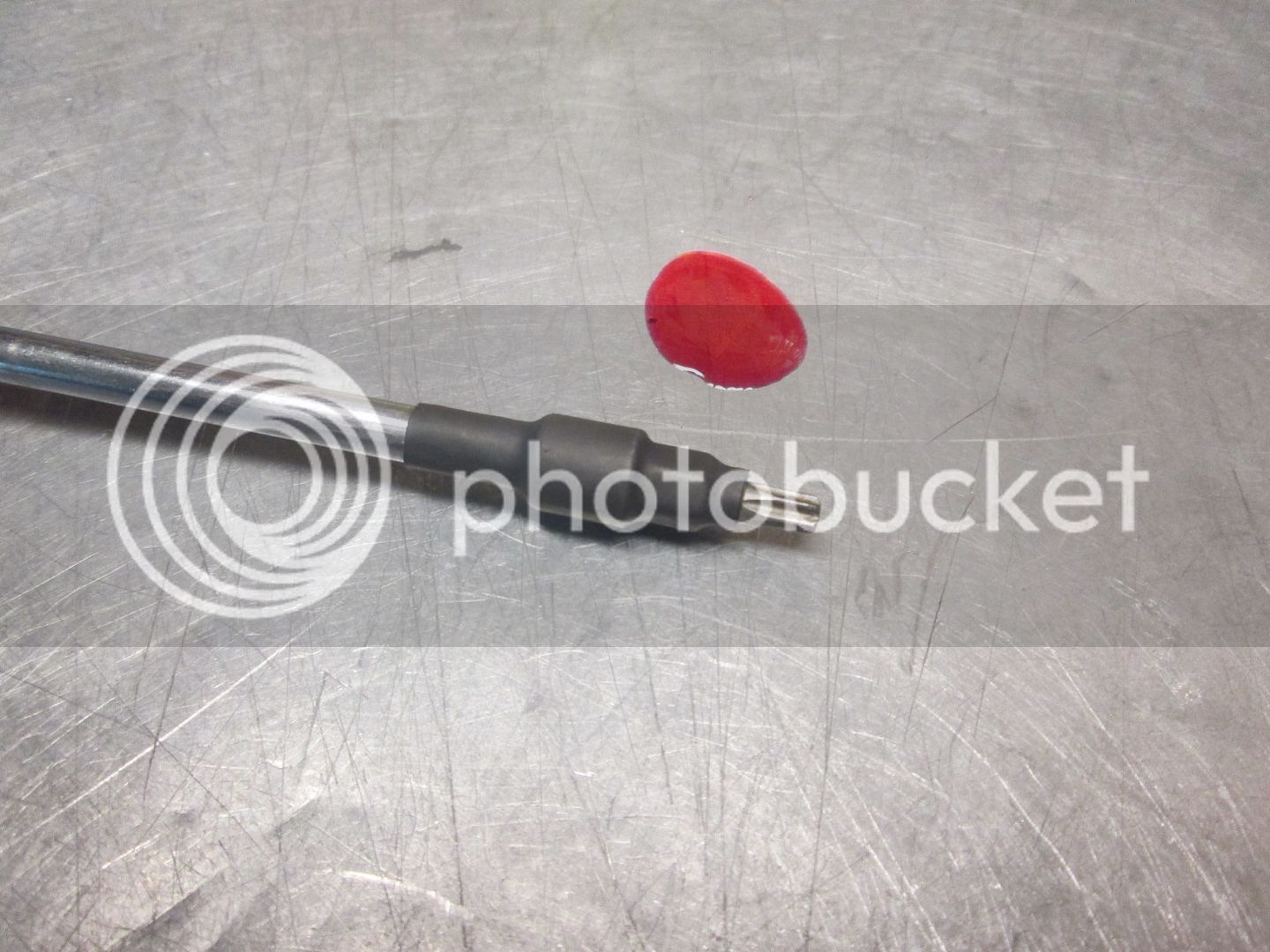

So, let's talk about timing numbers for a minute.

Stock:

Squish: .034

Ex: 105°

Tr: 116.5°

Stratos: 71°

In: 73°

Ported:

Squish: .020

Ex: 105°

Tr: 116°

Stratos: 75°

In: 78.5°

Have you tried more blowdown, ending up with 346 like numbers? Just pointing out the obvious, but you could try that by simply not raising the transfers back up after the machine work.

BTW, very pretty work!

That would be a bad move on a strato engine.......remember, it's just fresh air that's coming in when the transfers first open.

Does the 550 have case stuffers?

That would be a bad move on a strato engine.......remember, it's just fresh air that's coming in when the transfers first open.