Try tilting the rails/mill - like this.notice I had to put a counter weight on the nose end. is that because of my set up @BobL ?

I ruined a nice 24Ft slab of Pine that maxed out my 60" mill because I didn't realize the nose end was lifting up.

Try tilting the rails/mill - like this.notice I had to put a counter weight on the nose end. is that because of my set up @BobL ?

I ruined a nice 24Ft slab of Pine that maxed out my 60" mill because I didn't realize the nose end was lifting up.

I don't think the winch would have influenced it, but maybe it could have.I have yet to do any CSMilling but am Seriously Lurking here for information (AND There is a LOT of it)

I Read to Not drive the wedges as it can lift the slab/board and influence the cut. POST 185 by Hurchalla

Is The chain sharpened evenly ( I'm sure it is but I have to mentally check it off)

Is your winch line somewhat level/parallel with the kerf/cut line or is it pulling down (influencing) on the front of mill rig and possibly lifting on back of mill rig??

What kind of winch line are you using? (Fishing for Information)

The winch is what I Am looking at as your nose issue

I am looking for info as I am working towards cutting a Large Long Burr Oak but it will have to wait until I get some experience.

Thanks for posting the Video and nose counterweight issue/concept. Food for thought as a preventative practice

ok thanks. is that a hand throttle I am seeing?Try tilting the rails/mill - like this.View attachment 986717

Look here for full details - https://www.arboristsite.com/threads/modding-the-bil-mill-to-take-the-880.87987/#post-1369623ok thanks. is that a hand throttle I am seeing?

I caught myself questioning a few things about my comment ; Mostly the nose rising not the complete back rail My way of thinking would have the saw diving down the whole width of cut, not bar nose only.I don't think the winch would have influenced it, but maybe it could have.

Much as I felt I'd learned from Bob in years past, I found a lot I'd never actually put into practice. Had left this forum for awhile as Bob got quiet on it and posts went to a trickle, but the Facebook CSM group I joined has proved a bit disappointing after high initial hopes for it and a bit of knowledge gained. Someone on the group showed a Hi-Lift log jack device I liked that I realized looking back at the AS archives was just a copy of Bob's jack, and promptly made one of my own out of shop scrap. Got me looking at all Bob's devices and suggestions again. I like his Unistrut rail guide too, I was planning on putting one together with the same threaded rod rungs and hadn't thought of just aligning and joining extra sections like he does for long cuts. Most people just use Unistrut for first cuts propped on end brackets, so don't bother joining the rails like a ladder, but I want a rigid ladder-like structure for every cut. My cheap ladder flexes way too much. I only looked at Unistrut in person for the first time at Home Depot this week, and never realized how incredibly heavy duty it was. Would have switched to it long ago had I known. Also have gotten enthusiastically into lo pro gear and milling for most logs under 30" lately. There's literally a great companion book of more modern knowledge and devices and techniques to Malloff's "Chainsaw Lumbermaking" that could be compiled from all of Bob's posts on here.Hey BobL, thanks again for compiling and igniting this thread. I managed to get a beautiful finish on this cut re ently. I'm a bit rusty, but this restoked my enjoyment in the process. The knowledge and experience you share certainly helps those of us with less know-how to dive in!

View attachment 997322View attachment 997323View attachment 997324

Yeah, I'd never survive FB without FluffBuster - even then FB has tried every way they can to make parts of FluffBuster not work. A number of my friends have had all kinds of drama with FB if they've alarmed any of the AI bots by saying the wrong thing. I kind of have to use it as a marketing tool cause I'm an author/historian as well as a woodworker, but was perfectly happy before FB came along and am sure could be perfectly happy without it. Write that book someday! But I hear ya, I keep too busy milling and woodworking to write most of the time cause there's just no money in writing and I can do it all I want when I can no longer pick up a chainsaw. Actually have 16 hectares north of Bundaberg in QLD that I bought for my Dad 36 years ago that I haven't been to in 30 years. Was all scrappy smaller gum trees back then but maybe there's something worth milling there by now. It's ironic that all the information at people's fingertips there is these days, this long history of milling info to be mined here and other sites, and the vast amount of new millers are still crawling around on the ground trying to figure out why their chains don't cut better. Not enough curiosity and desire to work smarter not harder. Partly I think that's the China clone effect of all things milling - you can buy a cheap clone saw, mill, chain, etc, so a lot of new guys haven't had to figure out the first thing of building/tweaking/fixing anything themselves. My proudest moment in the past five years was fabricating my own industrial strength 20 ton shop press from the ground up. All American steel from the local steel recycling yard, 2 x 3 rectangular tubing and 4 x 5/8" steel flat bar, and Ford 351 bolts from a dead engine I dismantled. Absolutely bombproof. The Chinese frames bend with like 5 tons of pressure. Every single Chinese product I've found fault with has usually been not to do with the precision of machining, it's always been the incredibly low strength of Chinese steel.Thanks George. I left FB about a year ago actually I have been blocked from using it by FB, but that suits me. When I joined FB I was getting lots of ads for sleazy women so I registered as a female but then to put up with ads for feminine hygiene products, so I started using FB with an ad strripper app called Fluff Buster which FB don't like. I also made lots of derogatory remarks about FB on FB until finally blokes me and they asked me for a security check - photo of me from my passport or drivers license. I declined and I have never been back. I use FB mainly to stay in touch with overseas friends an relatives but we now use private chat apps for that so I dont miss FB at all.

Back to your topic. I have thought about writing a a book. Maybe when I can no longer use a big CS?

Now I have the clamp bolt holes free on the mill, I can run wheel setups through them. There's been the knock on the standard Granberg accessory that it's only good for the top half of the log, which Bob compensated for on his custom setup by making his wheels adjustable height, but still always below the bar. While messing around with spacers on my bolts to keep the wheels fixed at a lower position, I thought, why not put wheels on the top side as well - four wheel drive lol. These are small old skate wheels, minimal diameter, but I have rollerblade wheels twice as wide I can try too if they prove better for wildly uneven logs. May be some flaw in my thinking here, but seems it should be a good cheap simple wheel guide solution. Can take them off easily when I do last cuts where I want the bar as low as possible (a good feature of bolt on vs clamping).

20

20

Sorry, my bad, Bob, I've usually just caught your early versions of things going through threads and you tend to be three steps ahead of me with your final advanced versions. Or also sometimes I skim too fast and don't fully absorb what you've done in the first place. Really top notch system.I've had topside wheels on BIL since 2009?

White Teflon ones adjustable height ones above the bar and Black HDPE below the bar.

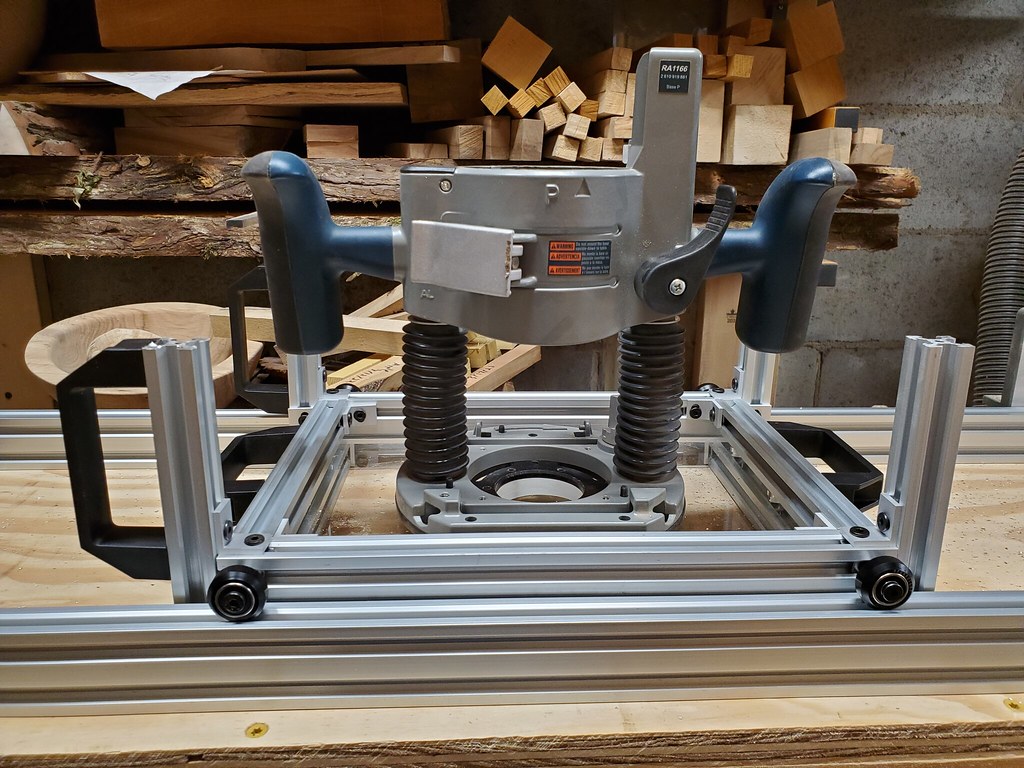

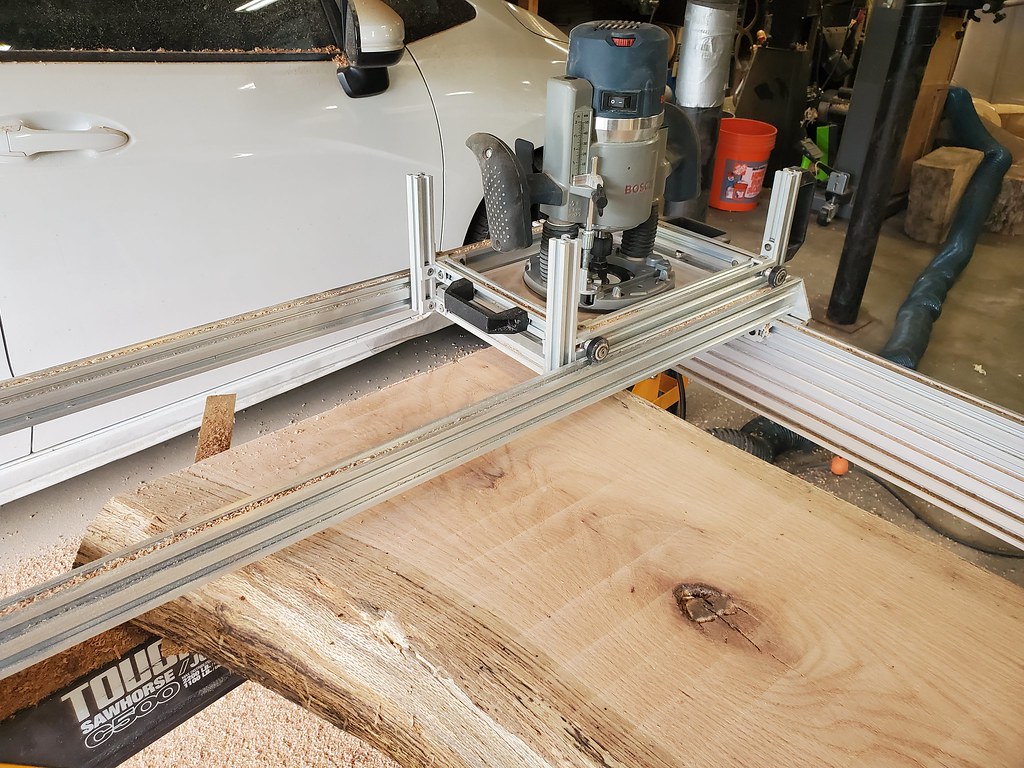

Excellent setup - I've always thought thought you could build some of the best setups with that but never yet been willing to commit the time and money to do so. I was thinking for my next router planing setup of doing something more like a manual version of a CNC router. Same rails and adjustable height router mount as CNC, just you move it around. People are doing it but with conventional flat cross sleds rather than raised bridges like CNC machines. Only downside to the bridge mount is I can only mount my Bosch 2 1/4 hp router rather than my 3 1/4 in the CNC router housing. My desire for a raised bridge like on a CNC versus everyone else's manual router sled designs I've seen with CNC rails is most people are limited to milling slabs in the 2-4" range unless they put risers under their rails to do thicker pieces which seems an extra bother. Which is fine for most people because that's all their doing is slabs that size, but I want to have a wide range of thicknesses I can easily adjust to do from 1-6".It was expensive to get all the aluminum and the fittings, but it did exactly what I’ve been wanting to be able to do, and I’ll be getting more to keep on hand to build more fixtures and jigs, as it is really versatile for these things.

I hope this gives some of you ideas of what you can do and build with!

No worries George.Sorry, my bad, Bob, I've usually just caught your early versions of things going through threads and you tend to be three steps ahead of me with your final advanced versions. Or also sometimes I skim too fast and don't fully absorb what you've done in the first place. Really top notch system.

Yeah, I've been thinking about this for a long time, but the cost always made me hesitant - I spent $800 to get everything that I felt I needed and to have enough extras just in case. I also intend on spending another $700ish to add more capability and options for the future, but I do feel comfortable with that now that I've seen what I can do with the material and the fittings.Excellent setup - I've always thought thought you could build some of the best setups with that but never yet been willing to commit the time and money to do so. I was thinking for my next router planing setup of doing something more like a manual version of a CNC router. Same rails and adjustable height router mount as CNC, just you move it around. People are doing it but with conventional flat cross sleds rather than raised bridges like CNC machines. Only downside to the bridge mount is I can only mount my Bosch 2 1/4 hp router rather than my 3 1/4 in the CNC router housing. My desire for a raised bridge like on a CNC versus everyone else's manual router sled designs I've seen with CNC rails is most people are limited to milling slabs in the 2-4" range unless they put risers under their rails to do thicker pieces which seems an extra bother. Which is fine for most people because that's all their doing is slabs that size, but I want to have a wide range of thicknesses I can easily adjust to do from 1-6".