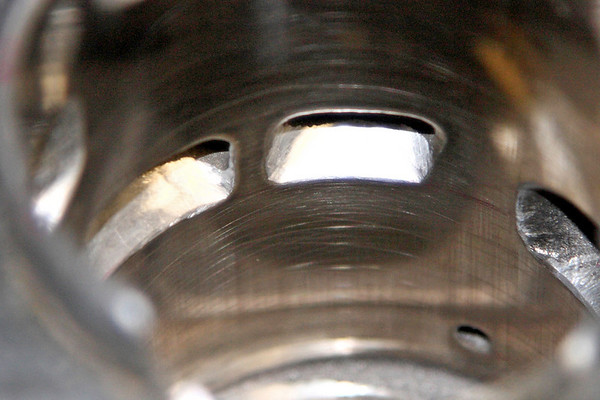

I noticed theres some moly left on the top. 372BB?

Exactly! I've got to give it to Scootr though. He nailed it right in the beginning.

I noticed theres some moly left on the top. 372BB?

Did you do some timed cuts with the stock BB setup so you could measure gains? Can't wait to hear how that thing runs! Cutting windows that big in the piston make my hands sweat; you weren't worried about weakening the piston?

heres a comparison

044 meteor on the left and stock 372xp on the right

so how much is the factory port opend .

ive been going back and forth wether or not i think my 372 is faster dual port or single 1" but i havent timed it to know for sure

Good thinkin' Brad.