Its gunna be a limp world in a few years. Slow and efficient wins the race!

Not so. Several of us have modded stratofied saws with good success. But that's an entirely different discussion.

Its gunna be a limp world in a few years. Slow and efficient wins the race!

Not so. Several of us have modded stratofied saws with good success. But that's an entirely different discussion.

[snip]

This would also give more of a cooling affect. These are just my thoughts.

Guess I was too excited when the teacher asked the question and just got my hand up and blurted out the answer before I even turned the page! ......

Now.....I have the same cylinder and piston here on my desk waiting for the grinder. Plan was to leave the transfers at the same opening but slightly wider towards the intake side, square up the bottom of the intake, widen exhaust, do the bottom of the transfers just as you have, then use an 064 piston ( Meteor - also here on the desk) with a pop up that equals the gasket thickness plus a decent squish. The 064 piston is windowed, the rings are pinned in the wrong places and the inside rod opening is too small. So now it's back to the BB piston without windows and I will take what I need for squish from the gasket surface and use that for a popup......Plans Change....Thanks for your willingness to share............Bob

The piston windows are just one piece of the puzzle though. My 372BB has never been as strong as my 460 or 440. I know it can be. So I went back in yesterday to see what I could do about that.

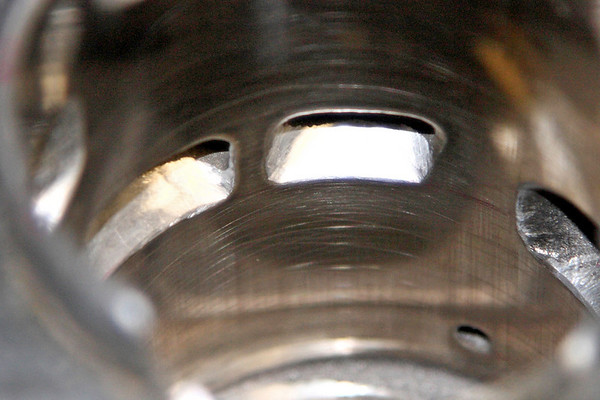

I started by raising the cylinder wall at the transfer opening at the base of the cylinder. I raised it by nearly 1/4". I wanted to open up the area where the transfers take in from the crank case. If the cases were split, I would have case matched those as well.

This opened up and created a dead space on the side of the piston.

So I got to thinking. Other saws have ports that are setup similiarly and have windowed pistons. Not only would that open up that dead space and allow it to be pushed into the transfers, but it would also aid in cooling the underside of the crown, and significantly reduce piston weight. What's to loose? So I threw caution to the wind and decided to try it.

But why the need for all the extra intake area? Well this is the main thing I was after here. I need more transfer area and timing. I raised the transfers a huge 8° and significantly widened them. I didn't not go all the way to the vertical lines, but you get the idea.

Here's the end result.

Ho ####.:bringit:

I'm looking roward to watching this one!

Ho ####.:bringit:

Are you guys in the sauce already...Ho and roward?...LOL

sean, i think it must be an Ohio thing...

Hey boy. You're going DOWN....................HARD!!!!!!!!!!!!!!!!!!

With all the work you put into that saw I hope I do go down.

Gettin' sceeeered?

Pretty cool Brad!! Got me thinking now!!

Yep, me too. I did what Brad did except I DID NOT add the piston windows (yet). I wonder if raising the base of the cylinder transfer slots will improve flow in combination with opening up the transfer uppers toward the intake side? Im gonna see if I notice a difference tomorrow.

The reason I went past that and did the windows was because raising the cylinder walls opened a large area of dead air space. Actually I'd love to see you run it like it is and then add the windows once you have a feel for it. I did a lot of mods at once, so I don't know which one did the most. But then again, it's the cummulative affect of all mods that adds up.