You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HF Chain Grinder Thread

- Thread starter Philbert

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Haven't gotten around to trying any yet. But on the HF website, you can scan through over 150 reviews of the current, bicycle brake lever grinder, and find tips and mods from other users, including some about adding a spacer for a tighter grip by the vise. Also, several related comments about the cutters rising up from the vise when grinding.

Philbert

Philbert

Still only $39.99 at the HF store in NKC.

The grinder goes on sale periodically for $40, then use a coupon for another 20% or 25% off. You can get the 'old' model off eBay for $30 - $40 (ask me how I know!). Not sure that I would recommend the bicycle brake (current HF) model, based on my brief experience and the comments of others here. Will play with the 3 styles and post more some stuff here. Hope others do as well!

I know of another A.S. member who bought one of those spinner/breaker combos but could not get replacement punches - which can break occasionally. A few guys have made their own replacement punches, but I don't have those skills. Bailey's often has a set that goes on sale for $100 - parts are available for these, and are a better deal IMHO.Found another item of interest there. Almost tripped my trigger except I would have had to gather up accessories (presets) to go with it.

http://www.baileysonline.com/Chains...aker-Spinner-Combination-with-Chain-Chart.axd

Philbert

On occasion I use the HF grinder that somebody gave me four years ago. It works OK as a dedicated raker dropper for a chain that needs a lot taken off in one pass. That's about all I use it for.

It works OK as a dedicated raker dropper for a chain that needs a lot taken off in one pass.

How do you do the rakers with it (and which style of HF grinder)? Multiple passes, slide the chain back-and-forth, etc.?

Thanks.

Philbert

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$14.99

$17.99

Fiskars Pole Saw Blade Replacement for Fiskars Pruning Saws and Tree Pruners, 15" Blade with Woodzig Chainsaw-Style Tooth Design

AMZ South Supply

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

Mine's the age old style, whatever they sold 10 years ago. I sometimes use two passes. The first one takes the front edge of the raker down and the second takes the trailing edge. I flattened the wheel's outside to make it easier. Unfortunately, these thin wheels cannot be replaced with wider ones, so it's a bit hit and miss. However, it's usually close enough.

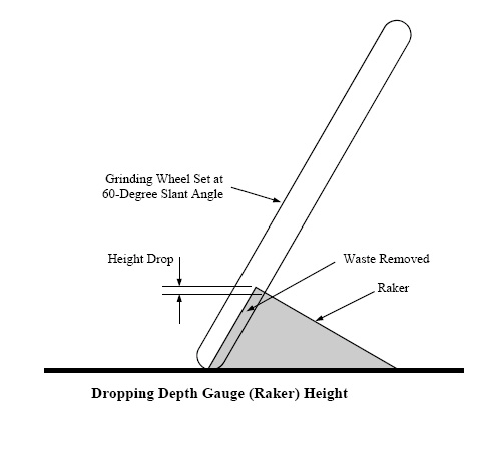

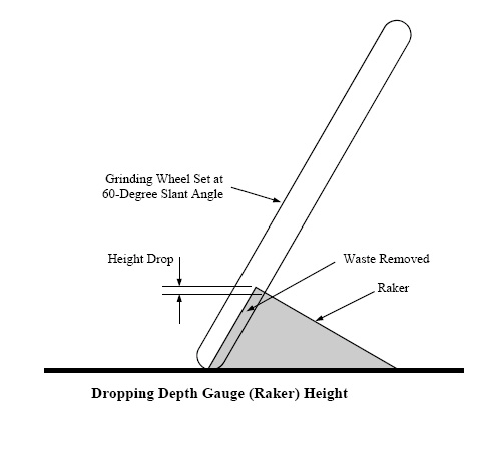

Regardless, using the Oregon 511a to drop rakers is now my preferred way of doing it. I angle grind the leading edge of the raker at 60 degrees (same setting as when sharpening cutters) using the back side of the wheel that rarely gets used otherwise. In this fashion I don't have to change the depth setting or the wheel, just the lateral tooth position and set the chain vise at 0 degrees. I suppose I could use the HF grinder to do all this as well. Here's a sketch:

Regardless, using the Oregon 511a to drop rakers is now my preferred way of doing it. I angle grind the leading edge of the raker at 60 degrees (same setting as when sharpening cutters) using the back side of the wheel that rarely gets used otherwise. In this fashion I don't have to change the depth setting or the wheel, just the lateral tooth position and set the chain vise at 0 degrees. I suppose I could use the HF grinder to do all this as well. Here's a sketch:

Note that the sketch shows the back angle of the raker as straight when actually it's more of a curve, concave downward. That means that more height drop will take place with subsequent waste removal as the chain gets used up. Initially it will drop slowly and later it will drop faster, so you have to be a little careful. However, I'm not having any difficulty with this technique and it's a bit of a time saver.

Interesting. You are shortening the length of the depth gauge/raker as well as the height? Look like they could get sharp/pointy at the top, or is this just the sketch?

In one of the videos, the guy brings his wheel down to the desired height and pulls his depth gauges through to take the height down, leaving a flat top. On my 511A I use the wider wheel to take just the tops down, then round the depth gauges back over to match the factory profile with a ScotchBrite wheel on a bench motor.

Philbert

In one of the videos, the guy brings his wheel down to the desired height and pulls his depth gauges through to take the height down, leaving a flat top. On my 511A I use the wider wheel to take just the tops down, then round the depth gauges back over to match the factory profile with a ScotchBrite wheel on a bench motor.

Philbert

Using my idea, they really don't get any sharper at the top because you are coming in at the 60-degree angle. They may actually be sharper at the top on a new chain. The raker profile remains almost the same all the way down with the curve remaining on the top.Interesting. You are shortening the length of the depth gauge/raker as well as the height? Look like they could get sharp/pointy at the top, or is this just the sketch?

In one of the videos, the guy brings his wheel down to the desired height and pulls his depth gauges through to take the height down, leaving a flat top. On my 511A I use the wider wheel to take just the tops down, then round the depth gauges back over to match the factory profile with a ScotchBrite wheel on a bench motor.

Philbert

About all I noticed is that I have to use my left hand to keep the stop tight to the chain and cutter, once it's set for the correct amount to remove from the raker. There is a tendency for it to lift up and move to the right (away from the wheel), even when the vice clamps are squeezed against the DLs . A tad slower vertical drop also helps, thus letting the grinder do its thing. Once again, you get better at it with a little practice.

lambs

Stihl crazy after all these years

Using my idea, they really don't get any sharper at the top because you are coming in at the 60-degree angle. They may actually be sharper at the top on a new chain. The raker profile remains almost the same all the way down with the curve remaining on the top.

About all I noticed is that I have to use my left hand to keep the stop tight to the chain and cutter, once it's set for the correct amount to remove from the raker. There is a tendency for it to lift up and move to the right (away from the wheel), even when the vice clamps are squeezed against the DLs . A tad slower vertical drop also helps, thus letting the grinder do its thing. Once again, you get better at it with a little practice.

I like the idea but I bet Oregon would have a cow over it. I may give this a try.

I generally hit the depth gauges flat across the top as Philbert does, then contour the front edges by hand with a couple strokes of a flat file.

!!!!

OK, what does this look like? Just saw it today, it is a new OREGON grinder (available March, 2015).

No idea what pricing will be. No idea from the photo how much will be metal, how much will be plastic, how it compares to the HF type models. Oregon usually makes or puts their name on pretty good stuff. Comes with a 3/8 inch wheel, with an optional* 1/8 inch wheel (*description says optional in some places, included in others). Looks like a fixed grinder head tilt angle and no vise tilt.

As the guy on "Laugh In" used to say, "Verrrry Interesting!"

Philbert

OK, what does this look like? Just saw it today, it is a new OREGON grinder (available March, 2015).

No idea what pricing will be. No idea from the photo how much will be metal, how much will be plastic, how it compares to the HF type models. Oregon usually makes or puts their name on pretty good stuff. Comes with a 3/8 inch wheel, with an optional* 1/8 inch wheel (*description says optional in some places, included in others). Looks like a fixed grinder head tilt angle and no vise tilt.

As the guy on "Laugh In" used to say, "Verrrry Interesting!"

Philbert

!!!!

OK, what does this look like? Just saw it today, it is a new OREGON grinder (available March, 2015).

No idea what pricing will be. No idea from the photo how much will be metal, how much will be plastic, how it compares to the HF type models. Oregon usually makes pretty good stuff. Comes with a 3/8 inch wheel, with an optional 1/8 inch wheel.Looks like a fixed grinder head tilt angle and no vise tilt.

As the guy on "Laugh In" used to say, "Verrrry Interesting!"

View attachment 393904

Philbert

That is absolutely identical to my 'Nick the Grinder'.

Made in Italy.

Last One!!! (?)

Ordered this one off of eBay, before I found out about the new Oregon grinder, above. Looks like the 'old' HF model.

Still looks and feels cheap, but less complex than the other two I acquired. Cleaned up some rough edges, added the foil tape to the post (as with the first grinder) to make clean up easier. Need to make a base for it. Have to print up some 'Silvey' labels before I can give it a fair trial.

One thing I like about this one is that the 4, self-tapping screws securing the wheel guard could be replaced with machine scenes and nuts if they strip out in the plastic from repeated use. This is not possible with the guards on some models. Since I already had one wheel explode, this is important to me.

Only has the 1/8" wheel.

Philbert

Ordered this one off of eBay, before I found out about the new Oregon grinder, above. Looks like the 'old' HF model.

Still looks and feels cheap, but less complex than the other two I acquired. Cleaned up some rough edges, added the foil tape to the post (as with the first grinder) to make clean up easier. Need to make a base for it. Have to print up some 'Silvey' labels before I can give it a fair trial.

One thing I like about this one is that the 4, self-tapping screws securing the wheel guard could be replaced with machine scenes and nuts if they strip out in the plastic from repeated use. This is not possible with the guards on some models. Since I already had one wheel explode, this is important to me.

Only has the 1/8" wheel.

Philbert

Except for the color, it does not look much different from mine, which is all orange. Yours might actually be newer. I'm surprised the owner still had the original carton. I stopped using mine after I bought my second sharpener made in Italy at an estate auction. My new one has hydraulic assist for chain locking. Heck, I did not know your were in the market for one of these.Last One!!! (?)

Ordered this one off of eBay, before I found out about the new Oregon grinder, above. Looks like the 'old' HF model.

View attachment 394065

Still looks and feels cheap, but less complex than the other two I acquired. Have to print up some 'Silvey' labels before I can give it a fair trial.

One thing I like about this one is that the 4, self-tapping screws securing the wheel guard could be replaced with machine scenes and nuts if they strip out in the plastic from repeated use.

This does not look possible with the guards on some similar models. Since I already had one wheel explode, this is important to me. Only has the 1/8" wheel.

Philbert

The clamp is adjustable on them. What works on .063 guage won't clamp .050 guage. You have to reposition the handle.

Yours might actually be newer.

It is new. They are still sold under a variety of brand names, in different colors, with a few design/manufacturing variations, as noted. Looked around on CL and estate sales for a while . . .

Heck, I did not know your were in the market for one of these.

Always interested . . . As noted at the start of this thread, I have limited expectations for these grinders, but trying to keep an open mind. Might find a niche use for one and keep it alongside my traditional Oregon grinder. How did yours work when you did use it? Any tasks where you might still use it and be happy? What do you like better about your Italian, hydraulic clamping grinder?

Thanks!

Philbert

spikin of which. did you ever try the others in that batch or get others and try?... Since I already had one wheel explode, this is important to me...

Philbert

spikin of which. did you ever try the others in that batch or get others and try?

I got some other wheels and will try them on 2 of these grinders. Waiting for the weather to warm up a bit so I can do it outside, and maybe some side-by-side comparisons.

The new Oregon grinder shows both the 3/16" and 1/8" wheels - conflicting information in the catalog whether it comes with one or both wheels.

Philbert

That is absolutely identical to my 'Nick the Grinder'. Made in Italy.

I wan't sure if 'Nick the Grinder' was the brand, or just an affectionate name for yours! So I Googled it and found this:

This picture looks like the one I just bought, above, made in China. The new Oregon 310 looks similar, but can't tell what types of materials are used, where it is made, etc. It appears to have access for replacing motor brushes, which is different. Will be interesting to see it in person.

Philbert

Similar threads

- Replies

- 38

- Views

- 3K

- Replies

- 45

- Views

- 4K

- Replies

- 550

- Views

- 66K