Hi Guys

I had a 330 given to me. PO said it had a bad EI. I put a new rubber carb manifold, chain and got it running and thought there is nothing wrong with this saw??? Wrong....after 3-4 minutes of hard cutting the saw died like you pullled the plug.

I put a NOS ebay phelon EI. $40

Success....

I cut about 2 pickup loads of red oak.... flawless except for dulling the chain in some dirt. My buddy using a husky 55 was duly impressed with the 330 also

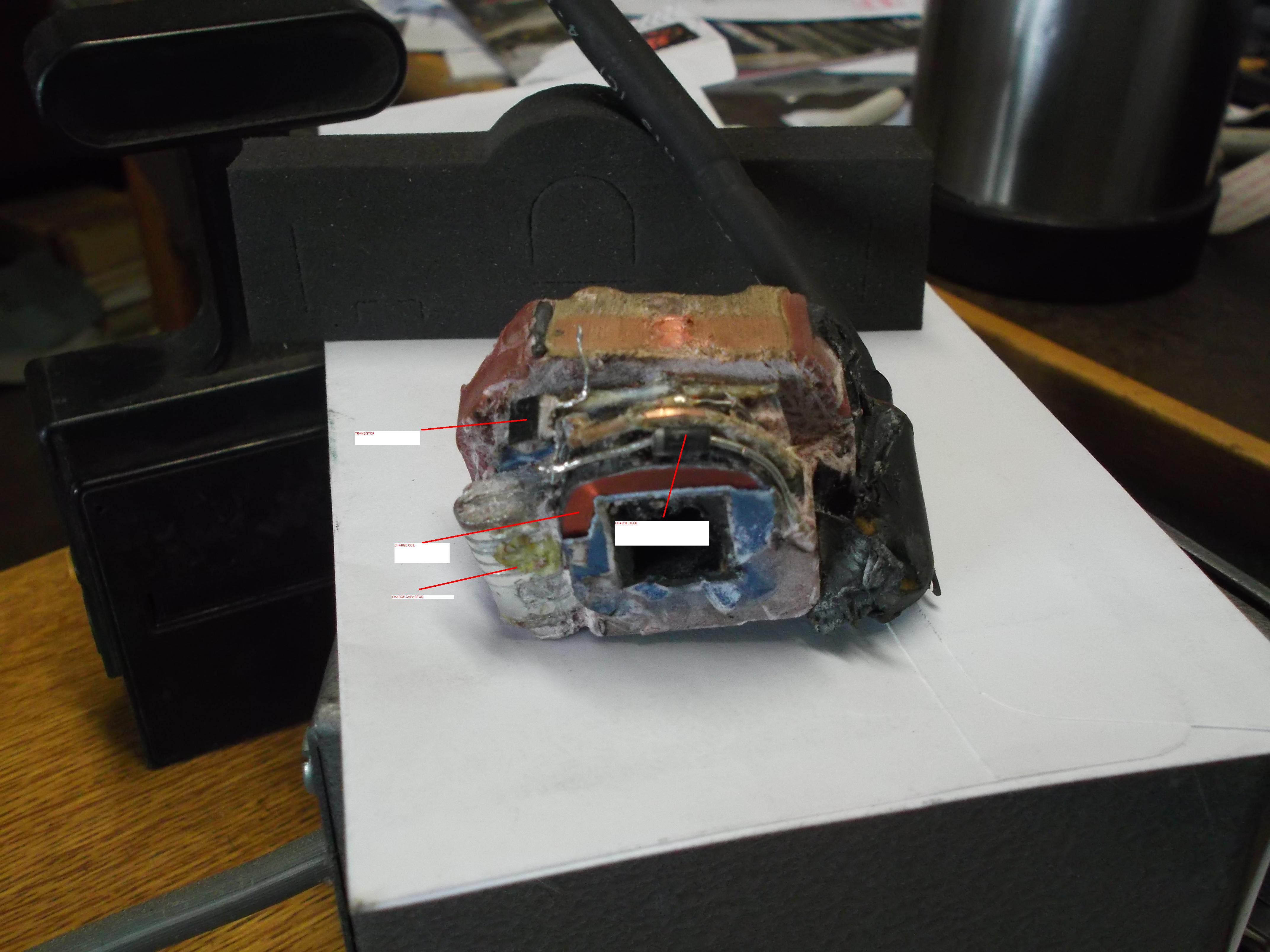

Since I've worked in electronics and electromagnetic s for 40+ years I was curious to see what's making that module tick... Taken a few annotated pix. limitations of my cheap camera are obvious but my eyes can easily see whats going on here...fix would be very difficult but swapping other EI on to another core lamination may be not to difficult.

1. There is a typical high voltage coil with insulation paper layers between the coil layers.

2. A coarser coil below that, in the blue coil form, is I believe a charge coil that produces the power to be trapped by a diode into the large charge capacitor (400v dc?).

3. Then at the mid point of flywheel (magnet) passing the coil... the zero crossing of the voltage pulse (single sine wave the transistor is triggered to dump the power from the cap through the coil primary....SPARK generated.

4. Simple CDI ignition

Bad (thermally sensitive until it finally dies) transistor or charge diode and the process goes down the toilet.