This past weekend I finally caught up with the guy that had a big but no model designation Jonsereds for sale. My initial thought was, "Heck, it's got a good sized bar sooo it must have some 'nads to pull chain on that bar!!???"

I had inquired here on post # 3228 and a few posts after that regarding I.D.-ing what model it might be. Things are pretty slim currently(having not won the lotto yet) but he had indicated that he would entertain a trade/yrade offer of ammo. Well I'm always up for a good "yrade"!!

Well ammo of the calibers he was interested in I did have, vs. green paper, sooo I threw a box of miscellaneous ammo together and arranged to meet the guy after work on Friday afternoon/May 2nd.

He was a cool guy(despite his inability to proof-read his CL listing) and we BS'ed about firearms and other saws he had for awhile before getting to the Jonsereds situation. I was kinda hoping that he wouldn't be able to get it to start/run as he had said it was more than a couple of months since it had ran and I could see it was in need of some TLC . Well after some choking and pulling he was able to get the Jonsereds to lit off and run at higher RPM but it wouldn't hold an idle. Sooo that got my attention, the fact that it actually did run, and we ended up working out a "yrade" deal.

I've had the good fortune of talking with a fellow AS'er that is into the Jonsereds 80/90 series saws. That has helped me immensely with learning what I'm up against with this saw; a big thanks to Kevin/Real1shepherd!! I finally started tearing into it last night and had fun cleaning a lot of gunk/residue off and removing some parts. By posting up this info I'm hoping to get some help/input/direction on getting some of the parts needed to bring this saw up to a better operating status.

First off -

The Muffler!!

This muffler has had a ruff life and I'd like to replace it with one that hasn't had the battering this one has seen!! I've seen ones that have outlets on the upper right side towards the chain and then the configuration like this one with exhaust gasses exiting right out the front. Is there any preference, as in does one work/flow better than the other??

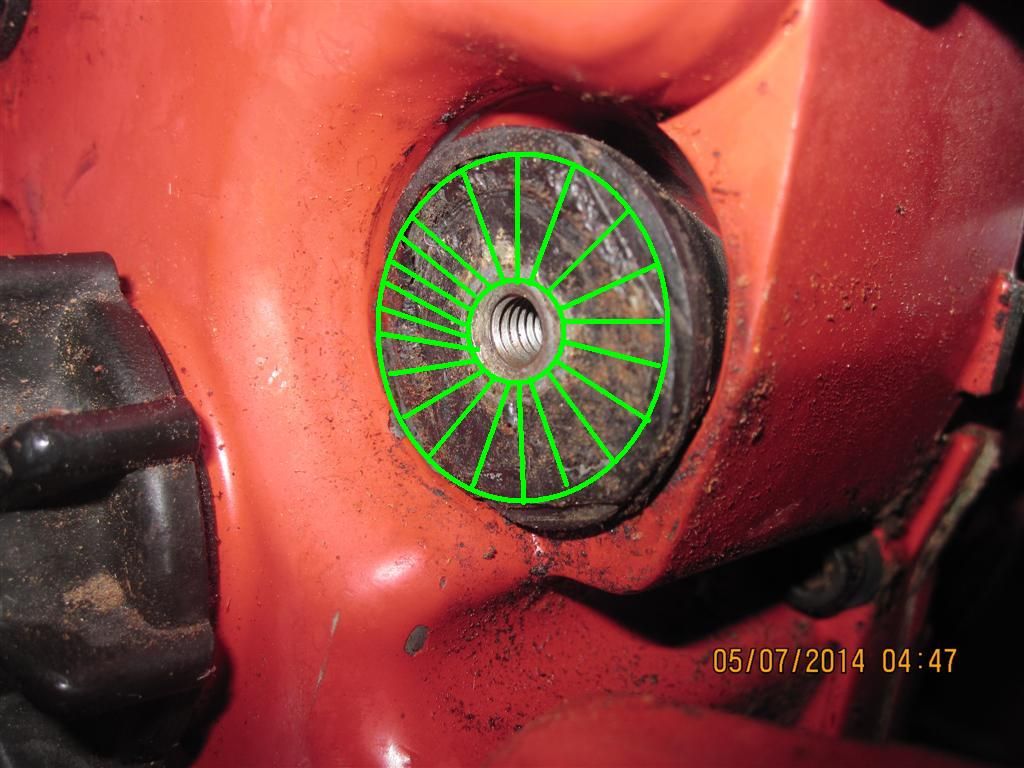

The next thing I noticed is the anti-vibe system is in dire need of attention. The biggest/loosest point is the one marked with the green box here. It REALLY needs some attention, the one on the left side of that casting isn't sooo bad.

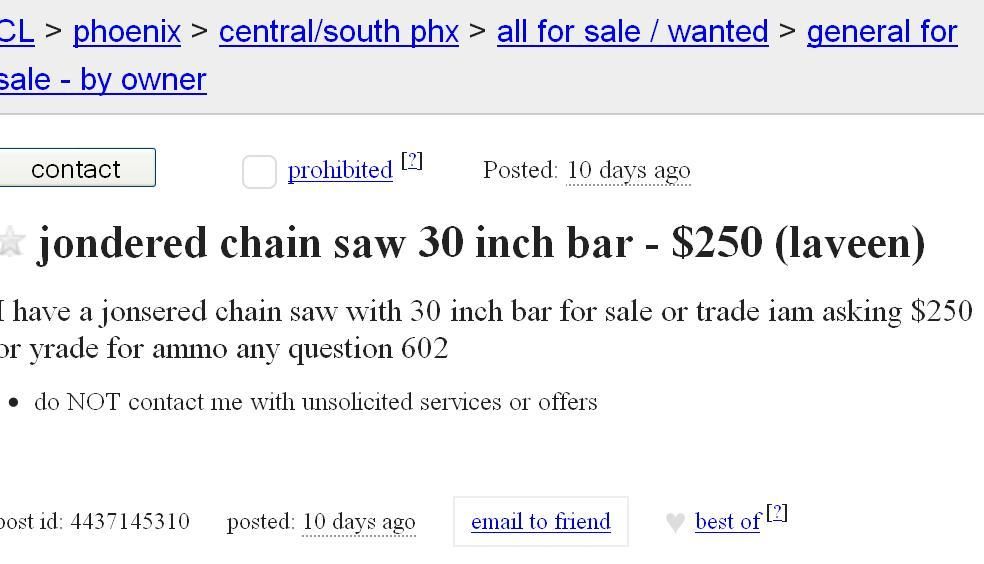

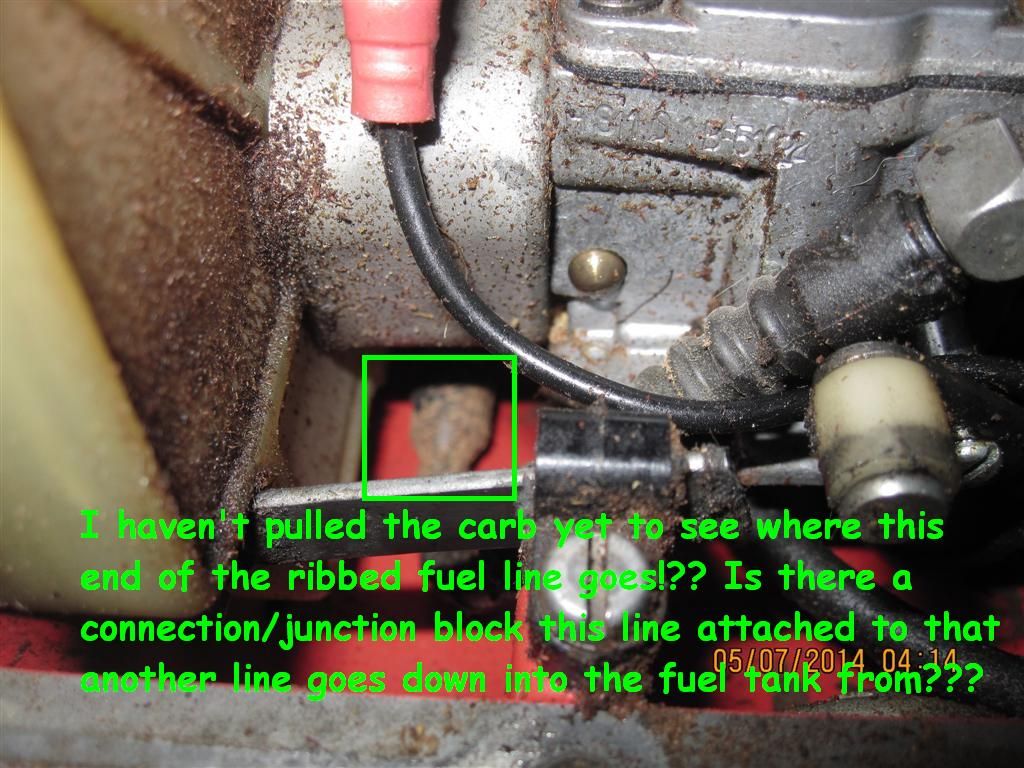

The throttle handle assembly is pretty loose on the two conical anti-vibe points where it mounts to the main saw body. I would like to replace those two pieces but have been told that they are pretty much unobtainium in NOS and kind of a crap shoot in "used". Has anyone tried to put the appropriate sized washers on top of these bushings to actually "shim" the bushings back into the conical casting holes?? I've attempted to illustrate my thoughts here;

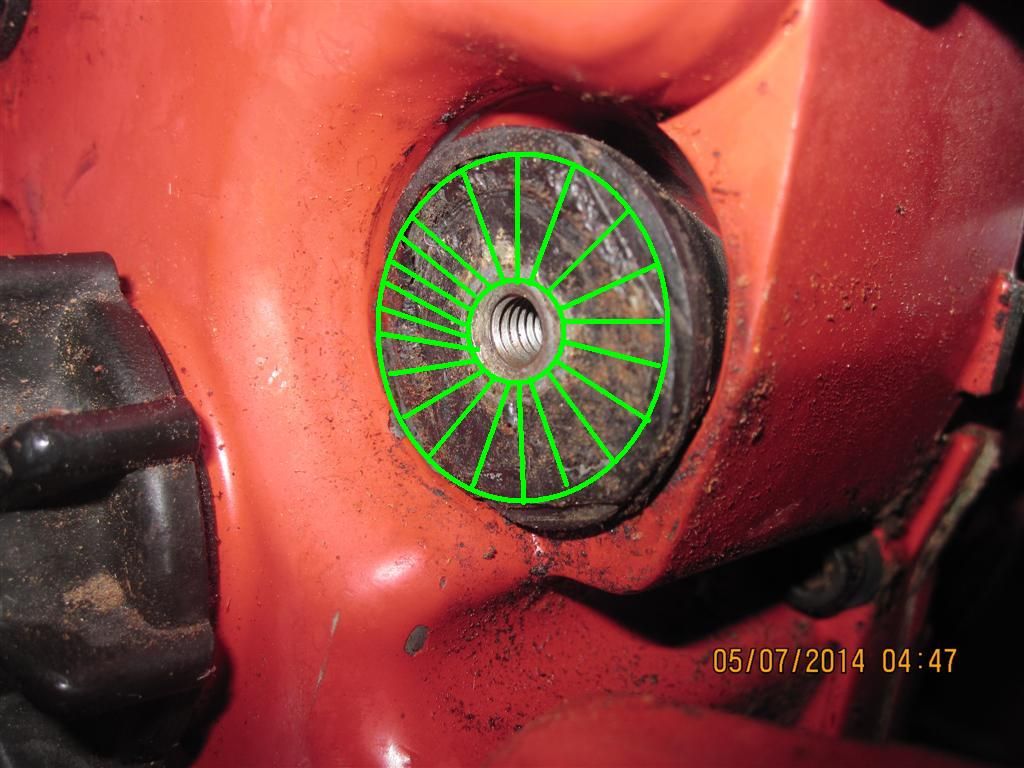

Anyways that's the start of this 90 series adventure!! I'll be picking up a carb kit, fuel line and a filter and getting that installed. Speaking of fuel line........what is up with this fuel line setup as I've never seen a ribbed line before!?? Also where I marked the green box on the picture below, what is that fuel line attaching to??? Is there a junction block where line then goes into the tank or ??? I'm not going to be getting around to pulling the carb any time soon so figured I'd put it out to those that have the knowledge about these sort of things!!