https://www.ebay.com/itm/MCCULLOCH-...N-BRAKE-Used/171710510699?hash=item27fabe766b

Mini Mac clutch cover with a simple brake flag.

Mark

Mini Mac clutch cover with a simple brake flag.

Mark

There are early versions of the brake on the Mini Mac with a flag at the top only, but later they went with the "full wrap" brake design to insure you would activate it no matter where you bumped the saw in a troubling situation. The 300 and 600 Series saws are the same way. They are ugly and add a few ounces but do lend a small safety factor.

View attachment 664486

This is a Power Mac (PM) 6 saw but there is a similar brake handle on early brake equipped Mini Mac saws.

View attachment 664494

Believe it or not, I do this for pleasure as a hobby. I will work on other peoples saws including Mini Macs but that is not my focus or goal.

Mark

Very unbalanced, I was wondering how much counter balance a 14" bar would give it. It's just way down the list of things to spend money on at the momentAbsolutely incredible write up, thank you for taking the time to respond with this knowledge. I certainly learned a lot over the past 6 months working on this saw, but these points are a great reference for future maintenance. That MiniMac 2.1 definitely is a different animal, instead of Eager Braver it's a Silver Eagle. Pretty cool.

I agree, this saw is a little awkward to use, has a lot of forward bias, not balanced at all.

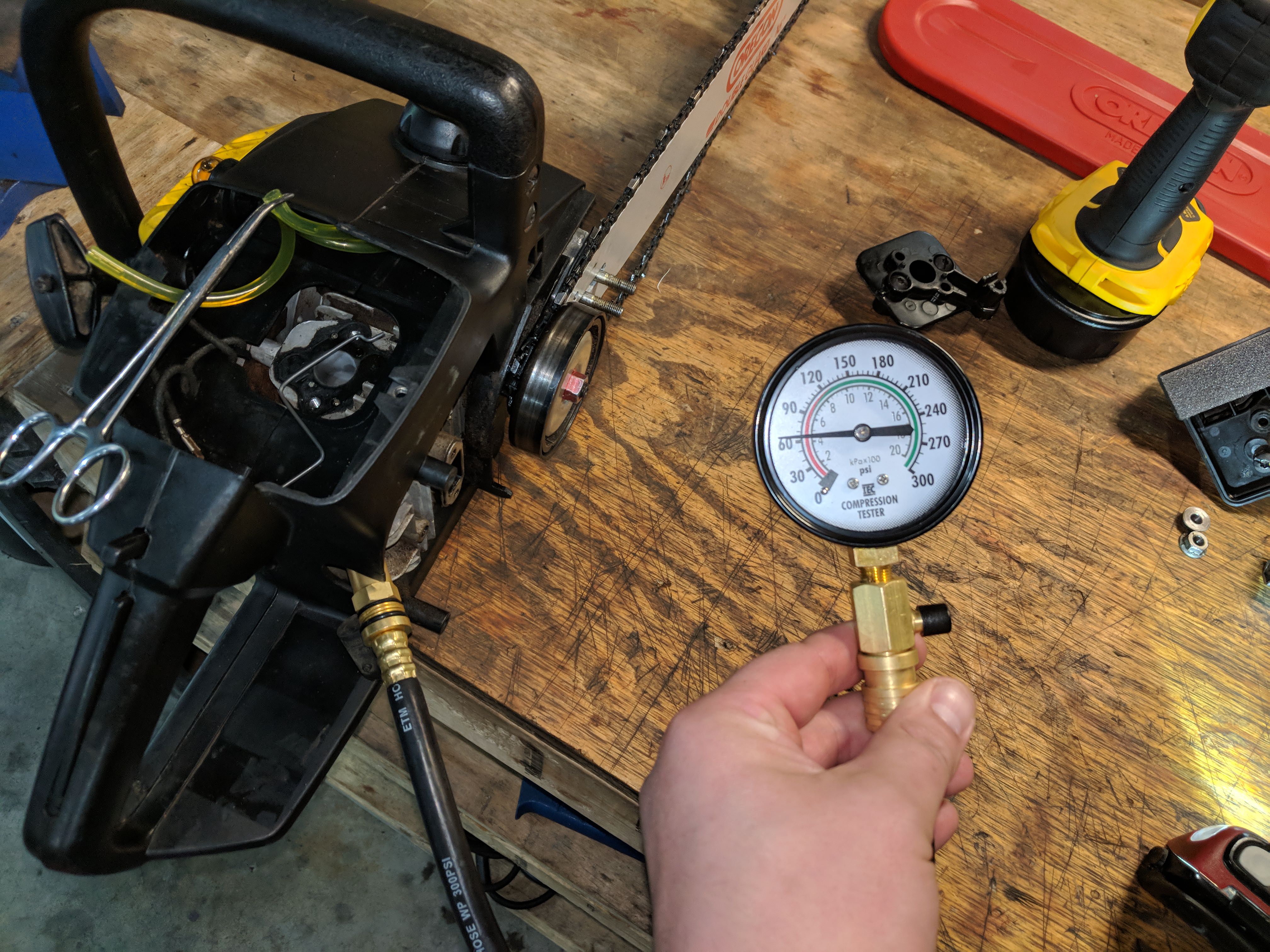

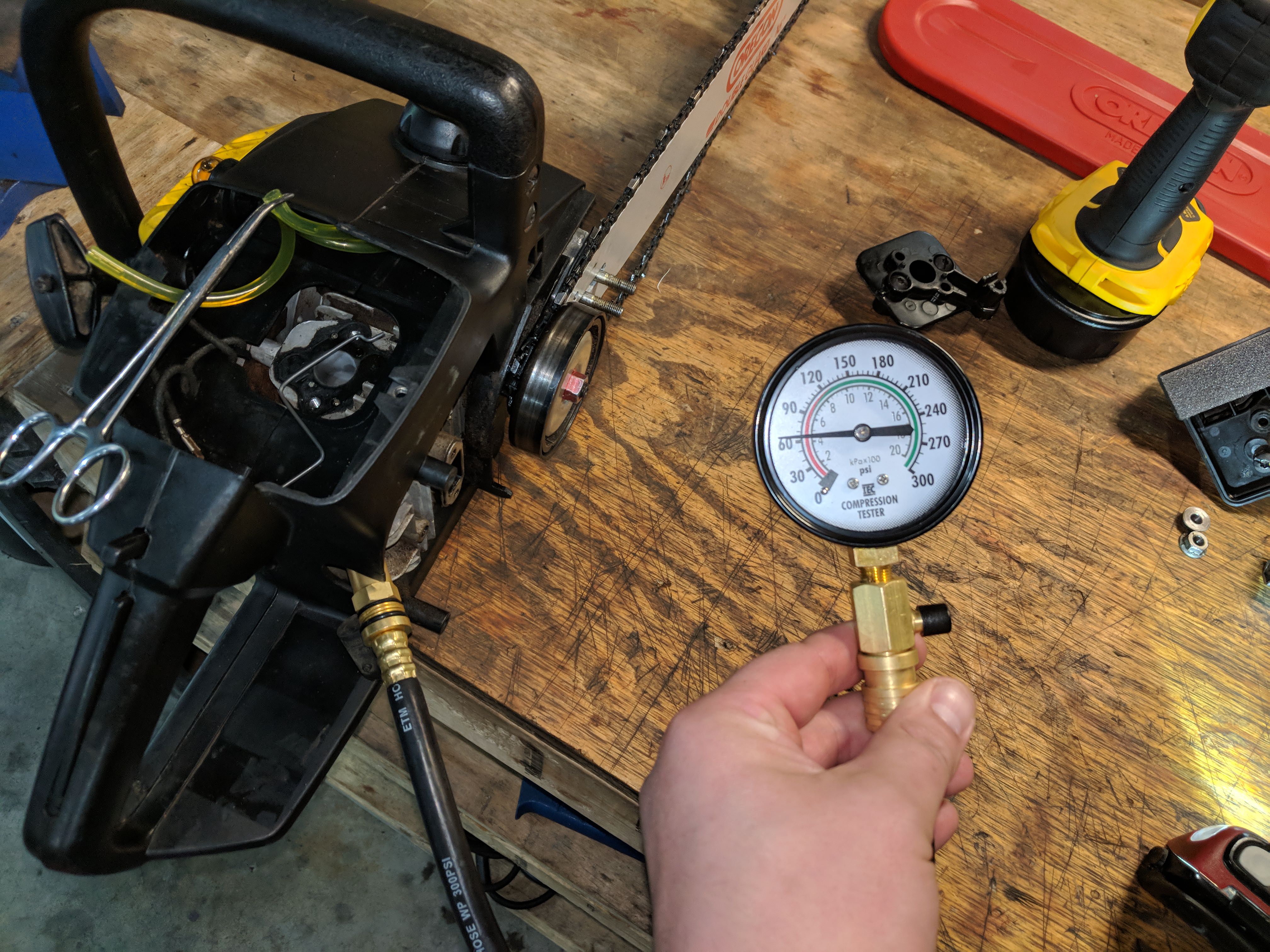

Have you used your compression tester on small engines before? My one is fine on a larger capacity engines, but with something as small as a chainsaw the volume of the hose can be almost equal to the compression chamber of the engine (my near new ms170 was reading 80psi). Where as the hose volume wouldn't have such a dramatic effect on the car engines it was designed for.Ignition and oiler seem to be a better scenario. I don't know why I didn't do this first, but after putting it back together (I'm talking about tge MAC 3200 now) - it tries to start, fires up, then in 2-3 seconds dies. I checked the compression and sure as *****, I'm only getting a hair over 60 psi. Took of the muffler and intake assemblies to inspect the piston, and through the intake port I'm seeing scoring on the piston.... probably the cylinder wall as well. Oh well, I was only $17 worth of parts and about 2 hours into it.

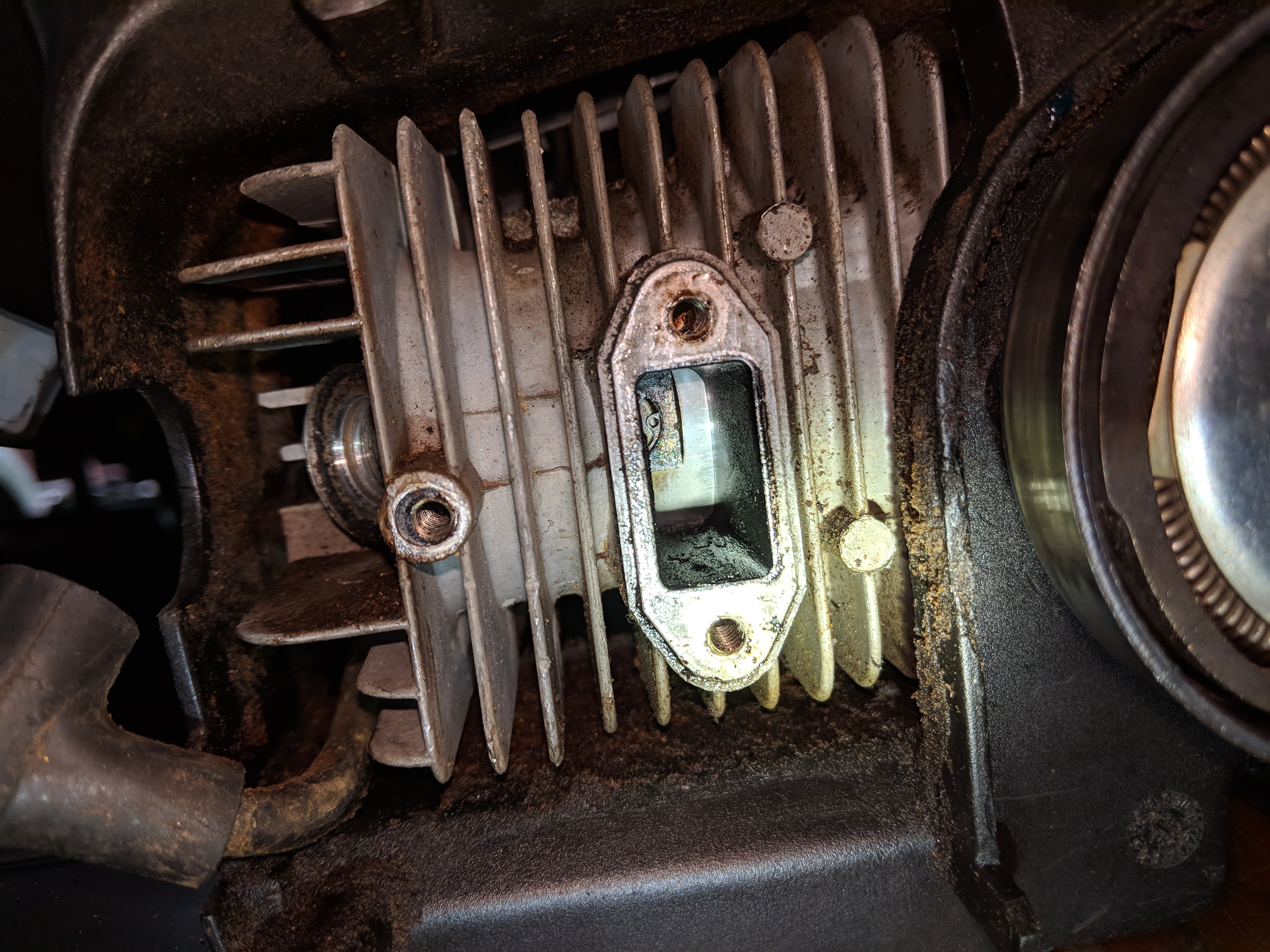

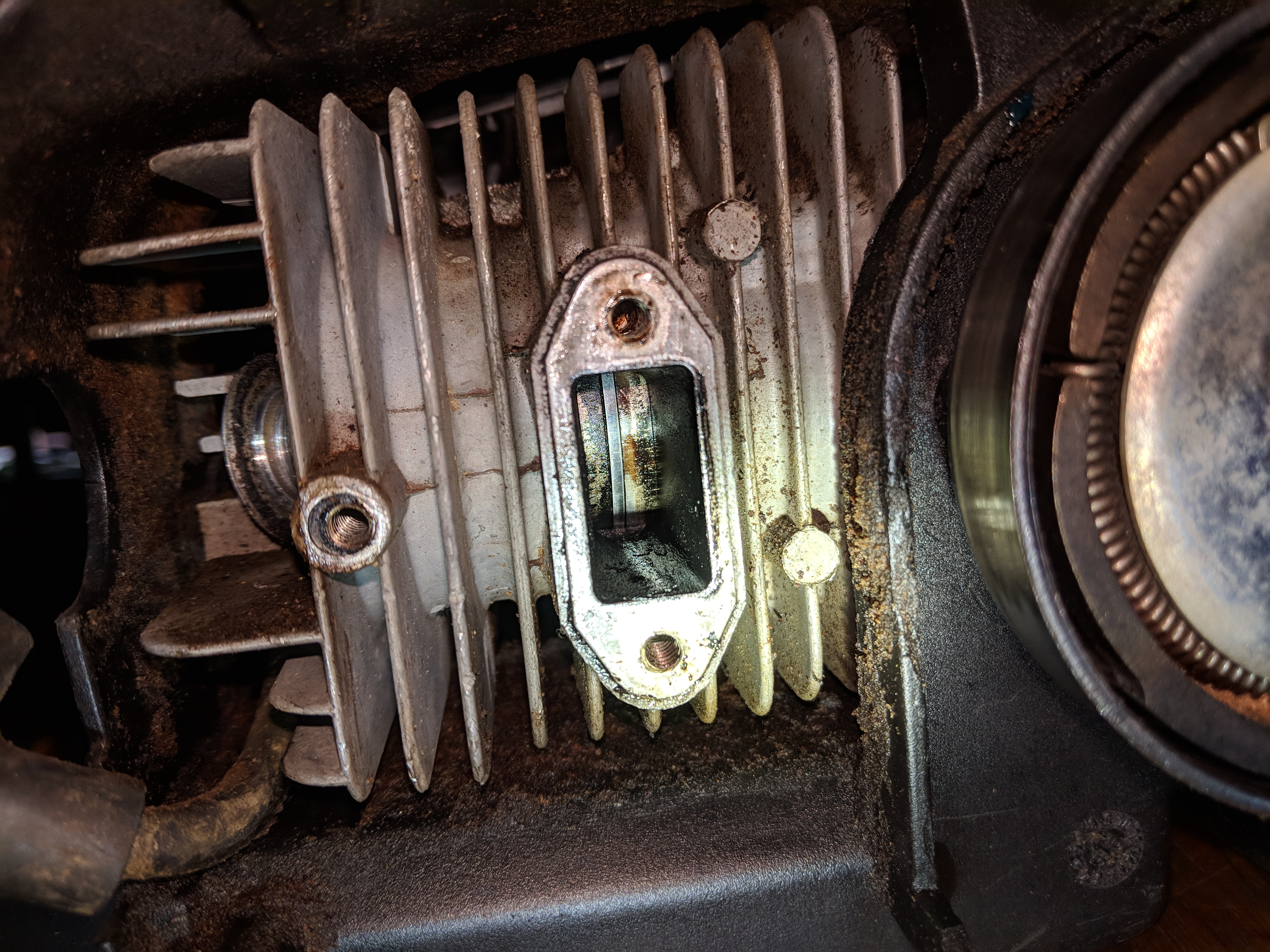

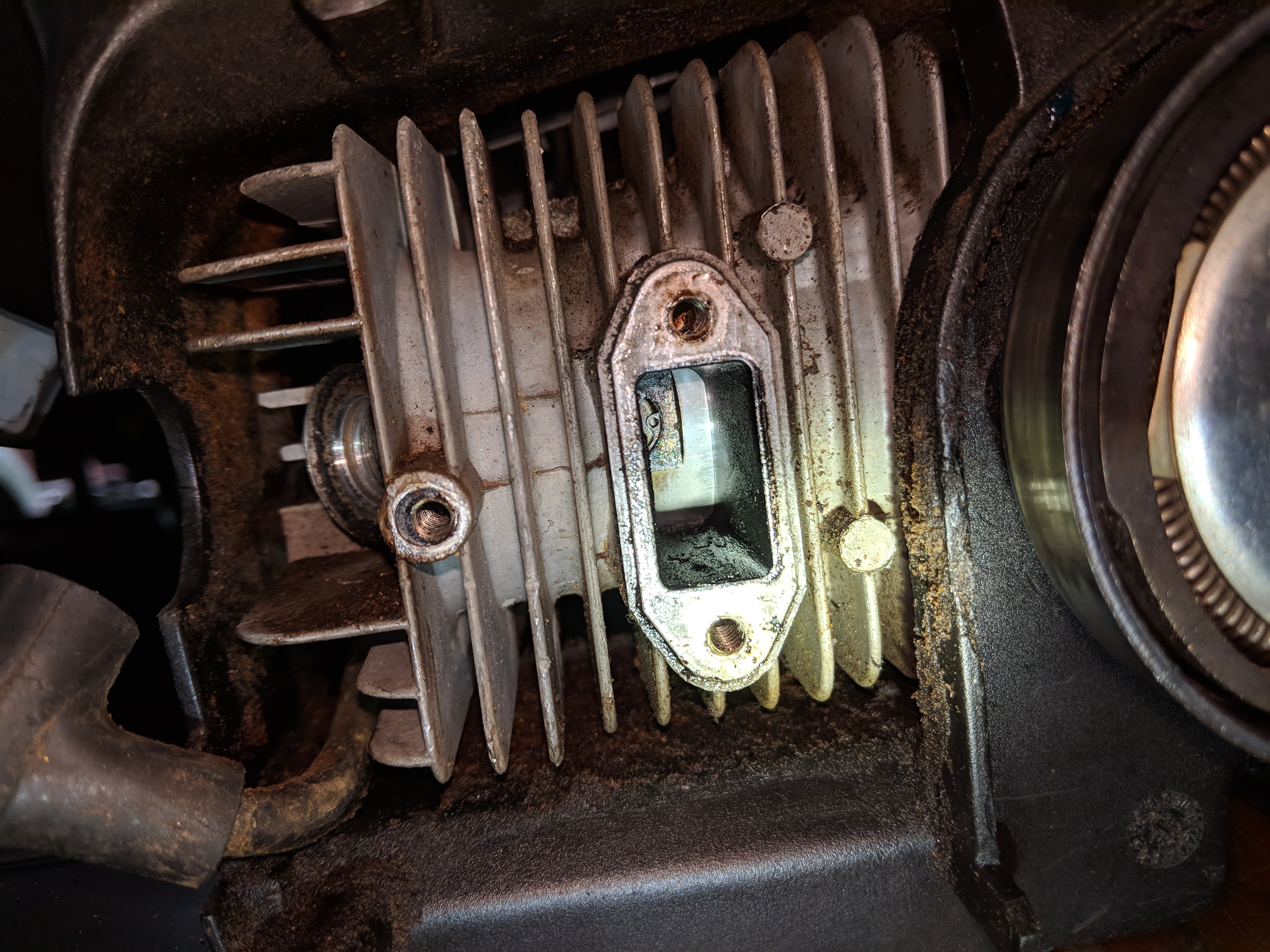

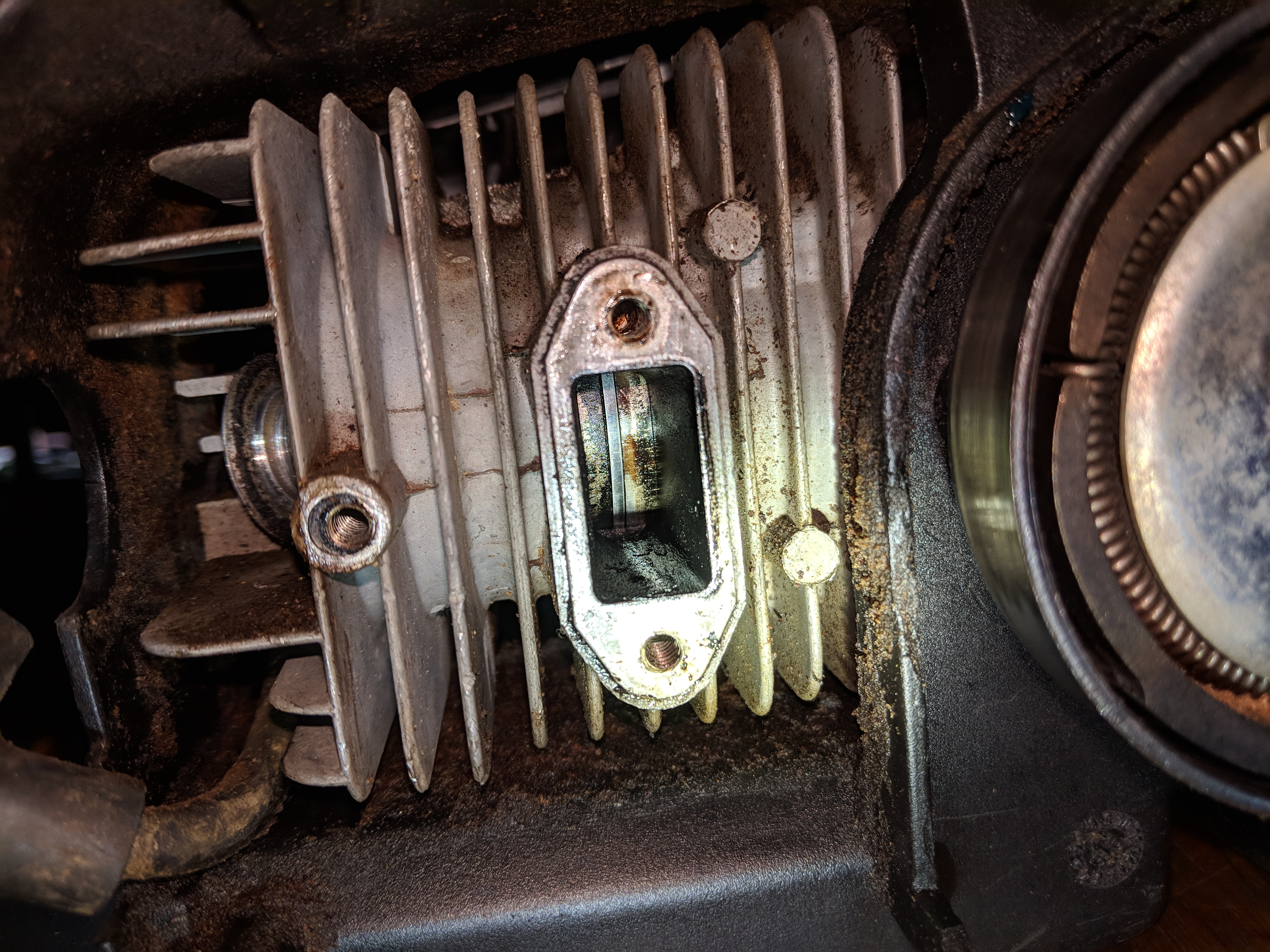

Piston appears okay here:

But here I see some scoring, used a polymer pick for tactile feedback and I feel a ridge:

Very unbalanced, I was wondering how much counter balance a 14" bar would give it. It's just way down the list of things to spend money on at the moment

Have you used your compression tester on small engines before? My one is fine on a larger capacity engines, but with something as small as a chainsaw the volume of the hose can be almost equal to the compression chamber of the engine (my near new ms170 was reading 80psi). Where as the hose volume wouldn't have such a dramatic effect on the car engines it was designed for.

I think there's a thread on here somewhere on changing the valve placement or modifying them to reduce the air volume before the guage , I haven't done anything to mine yet. I thought about shortening the hose right down, but could be a pain to get it to thread down tight into the sparg plug hole on some engines thenIt was, I found an OEM 12" bar and chain on eBay for $25, now it's much more easily wielded as it is intended, a limbing saw.

Funny you should mention that, because this compression tester is new, recently purchased. Before, I borrowed one from a guy at work, who changed jobs a few weeks ago so I bought this on a whim because I needed one again.

Might have to check my other saws for comparison...

Does anyone have a manual for the eager beaver 2.0 60012312?!?!?