You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Log splitter not building pressure

- Thread starter ctf58

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

You might be able to get seals from a tractor dealer. Take cylinder off of splitter, open it up, investigate the conditions. Might not be only seals.

Old-Feller

Pretty Fart Smeller

Old-Feller

Pretty Fart Smeller

When I built my splitter I used shop air to extend the ram to give me an idea of where I needed to weld my wedge on, Any way, you could extend the ram all the way with the engine and the hyd pump, Then shut it off and disconnect the push side hose and hook up shop air to the cylinder, If it bleeds past, that would let you know if that was the problem whereby eliminating or confirming the seals inside of the ram.

ctf58

ArboristSite Lurker

How long should I wait to see a difference in pressure? I hooked up a tank with 100psi to the inlet port at the top of the ram? Do I need to actuate the valve?When I built my splitter I used shop air to extend the ram to give me an idea of where I needed to weld my wedge on, Any way, you could extend the ram all the way with the engine and the hyd pump, Then shut it off and disconnect the push side hose and hook up shop air to the cylinder, If it bleeds past, that would let you know if that was the problem whereby eliminating or confirming the seals inside of the ram.

dave ensign

Trapshooter

Your being given bad information. It looks like fluid is passing by your piston with pressures of more than 500 lbs. A 100 lbs of air pressure would tell you squat. What you should do is fully extend the ram with your pump, then disconnect the pressure line at the front of the cylinder (end with the rod sticking out). Start your engine and push the control valve handle forward. If oil spurts out the open port in the cylinder the cylinder is bad. If no oil comes out, the problem is in the valve.

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

ctf58

ArboristSite Lurker

1st pic outlet from bottom of tank to filter then to pump.The pressure relief valve is probably built into that cone shaped protrusion on the new valve you installed. Sometimes they are built into a separate area of the valve. If you saved your original documents, it should at least be mentioned how to adjust the pressure relief valves.

Since your engine keeps running when it is stalled on retract, I am assuming that it is set about right, and shouldn't be the problem. How 'bout you tell us what model of valve you bought, and we can find out more info on that?

I continue to think that it isn't the cylinder, however. No amount of "bad seals" will cause the tank to overflow. I've bought far more hydraulic cylinders over the years that the average joe with a log splitter, and I've never had one that failed when new. I think that is the last place you should be looking.

I want to see proof that the hydraulic motor is being spun in the correct direction. I would like to see the details on the casting of the hydraulic valve to make sure it isn't being fed oil from the wrong side. And I want to see something that assures me that the oil is being picked up from the bottom of the tank (or close).

I believe that something is letting air into the system. You said the high pressure lines were loose, yet didn't leak. In my opinion, that cannot happen.

And... I have not heard any reports as to whether there was a check valve located anywhere on the system. One little check valve in the wrong spot can cause troubles, as can a pressure relief valve.

2nd pic box of new valve.

3rd and 4th .pics of Valve installed.

Pressure guage on "In" side of valve

Attachments

ctf58

ArboristSite Lurker

Getting ready to do just that. I didn't think 100psi would do much.Your being given bad information. It looks like fluid is passing by your piston with pressures of more than 500 lbs. A 100 lbs of air pressure would tell you squat. What you should do is fully extend the ram with your pump, then disconnect the pressure line at the front of the cylinder (end with the rod sticking out). Start your engine and push the control valve handle forward. If oil spurts out the open port in the cylinder the cylinder is bad. If no oil comes out, the problem is in the valve.

That is what it looks like alright. That being said, what do we do if it doesn't blow any oil?

Let's worry about any potential problems at the valve after completion of the cylinder test.

Let's worry about any potential problems at the valve after completion of the cylinder test.

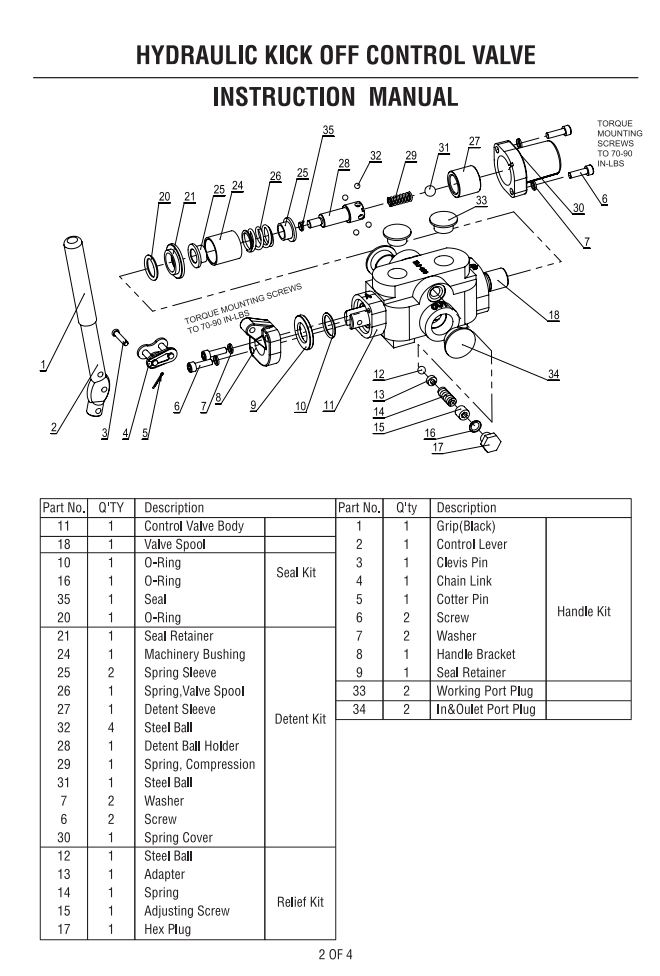

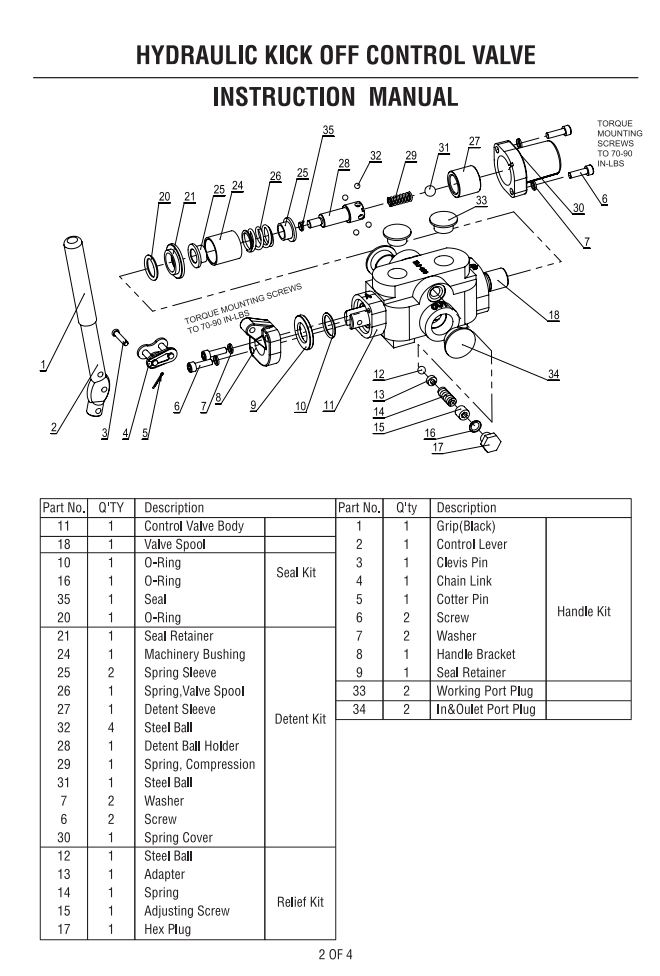

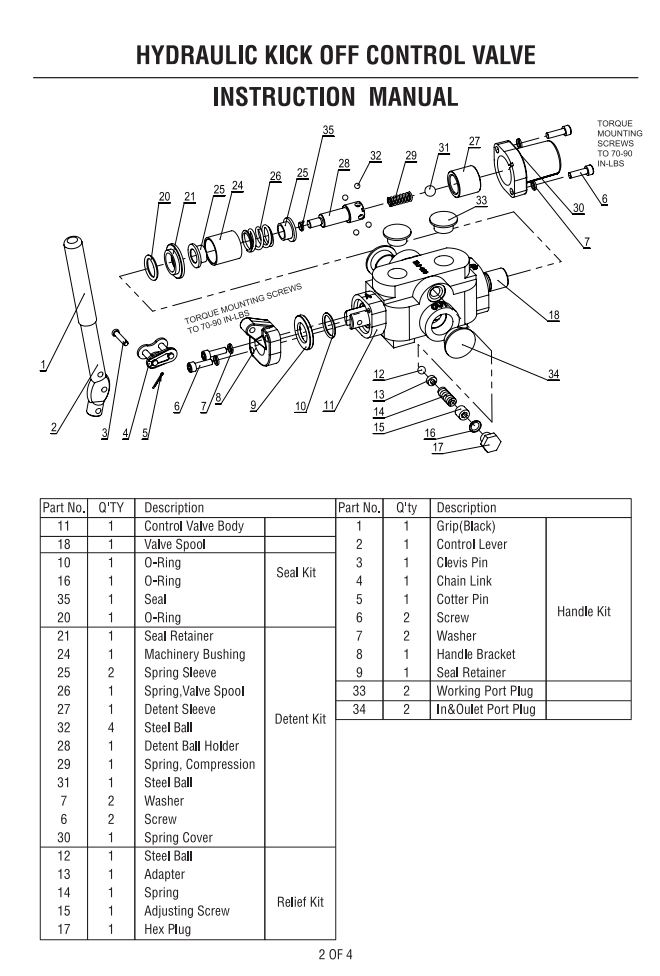

Here is the schematic diagram for that valve:

The diagram doesn't specify which port is for inflow and which is for return to tank. Is it marked on the casting?

The diagram doesn't specify which port is for inflow and which is for return to tank. Is it marked on the casting?

When I built my splitter I used shop air to extend the ram to give me an idea of where I needed to weld my wedge on, Any way, you could extend the ram all the way with the engine and the hyd pump, Then shut it off and disconnect the push side hose and hook up shop air to the cylinder, If it bleeds past, that would let you know if that was the problem whereby eliminating or confirming the seals inside of the ram.

It's rather dangerous to use air pressure on hydraulic cylinders. When parts finally start to move, they tend to fly destructively out of control.

ctf58

ArboristSite Lurker

Yes it has IN and OUT on casting and you can see in plumbing diagram the side with the adjustment port is the IN side.Here is the schematic diagram for that valve:

The diagram doesn't specify which port is for inflow and which is for return to tank. Is it marked on the casting?

Your hot spot is your leak. Cj

ctf58

ArboristSite Lurker

Ok, I plugged the "A" port on the valve. It is the valve the controls returning the ram. I put a nipple on the port on the ram end of the cylinder. I then started the motor with the ram already fully extended. And there was no fluid to speak of coming out of the nipple. When I moved the handle to extend the ram, I think the technical term is, "a **** ton of oil came out". I'll try to post a video but I'm no expert video pro.

ctf58

ArboristSite Lurker

Pressure never got to 400psi before I let off. I didn't want to wear oil.

I think I'd disassemble that cylinder and take a look at the innards. Someone previously reported that tie-rod cylinders were not very good. That's not my experience, however.

You'll appreciate how easy they are to take apart, and replacemenet parts tend to be commonly available.

Most folks would try to get warranty, or take it to a shop, but I don't think cylinders are that hard to work on. It helps if you have some of the bigger tools for pulling stuff apart.

I've got an excellent hydraulic shop, too. I can walk in with bad seals and they will match them up for me. Often on proprietary cylinders that the manufacturer doesn't make seals available for.

You'll appreciate how easy they are to take apart, and replacemenet parts tend to be commonly available.

Most folks would try to get warranty, or take it to a shop, but I don't think cylinders are that hard to work on. It helps if you have some of the bigger tools for pulling stuff apart.

I've got an excellent hydraulic shop, too. I can walk in with bad seals and they will match them up for me. Often on proprietary cylinders that the manufacturer doesn't make seals available for.

Just take the tie rods apart, pull the head end off with the rod inside the head end, sliding the piston out of the barrel. Most Chinese cyls just use o-rings for piston seals. My guess is they nicked the seal when they assembled it. If the piston is tight on the rod, replace the piston seal and check the bore for bad spots. If all good grease and reassemble. If the piston is loose replace the.o ring between the piston and rod. Your hot spot indicates the leak is between the.piston and barrel. This is one way I find leaks on large cylinders before they are removed from the machine. Be sure you head and cap o rings are in place when you reassemble. Alot of them get pinched. Cj

dave ensign

Trapshooter

Fix the cylinder, adjust the detent and split some wood!

Dave

Dave

Old-Feller

Pretty Fart Smeller

Looks like you figured it out to me!

as far as using air, Lets see 120 psi of air vs 2500 psi of fluid that does not compress, Nothing dangerous about it. I was a heavy equip mechanic for 30 years, Dealt with lots of hydraulics and have used air to actuate many different hyd devices in troubleshooting.

as far as using air, Lets see 120 psi of air vs 2500 psi of fluid that does not compress, Nothing dangerous about it. I was a heavy equip mechanic for 30 years, Dealt with lots of hydraulics and have used air to actuate many different hyd devices in troubleshooting.

Sure. You knew what you were doing. It's not quite the same instructions for less experienced people.

I pretty much know what I am doing, too, but I still find that separating or actuating hydraulic cylinders with air pressure is a bit iffy. Chain hoist or other rigid pulling device? Not so unpredictable.

I pretty much know what I am doing, too, but I still find that separating or actuating hydraulic cylinders with air pressure is a bit iffy. Chain hoist or other rigid pulling device? Not so unpredictable.

Similar threads

- Replies

- 42

- Views

- 2K

- Replies

- 9

- Views

- 395

- Replies

- 3

- Views

- 1K

- Replies

- 6

- Views

- 759