McC

ArboristSite Guru

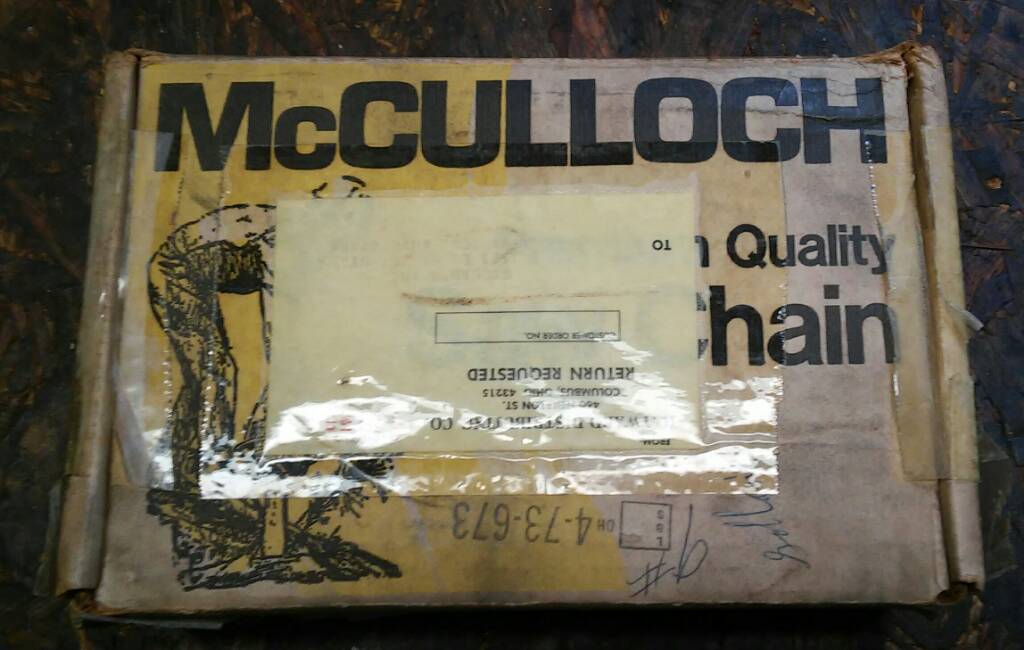

Mark, I ended up buying the banana handle power mac from Ken on Sunday, it was just too darn cute with the little McCulloch scabbard too.

Scott

Scott

This track should save you a little travel time. Vintage races on September 26. http://www.61kartway.com/Great photos Kris. I will have to watch for that event next year and try to visit.

Mark

Some while back in ended up with two McCulloch kits that can be used with the Mini Mac and Power Mac saws including the block off for the muffler and intake, the kits also have a rubber stopper to fit in the oil tank and fuel tank to allow you to test those. The muffler block has a rubber gasket, the intake uses and intake gasket or you can make your own from a piece of inner tube. I will point out that the drawer doesn't look anything like this now with bags of extra fittings, bits of tubing, large syringes that can also be used for pressure/vacuum testing, etc. The kits (93900) are in the bags.

View attachment 443726

I also picked up along the way a vintage McCulloch pressure bulb, the hose and check valve in the original unit were no good due to age but the bulb and gauge have remained viable.

View attachment 443728

I don't have any photos of the Power Mac or Mini Mac set up but the photos below show the pressure and vacuum testing being carried out on a 10 Series carcass (PM8200 I believe) with home made test bits made from steel and inner tube. It's yellow because I used it once when painting a short block.

View attachment 443729

View attachment 443730

It has been pointed out before but I will make the point again here, there is no real vacuum present in a reed valve engine so you can test and feel good about pressure and vacuum in a "reeder" but the vacuum is really superfluous in those models.

I will also note on the PM8200 photos that those engines are equipped with the "Q" port so the port for the compression release above the muffler is not drilled through, thus you can have pressure and vacuum with that "port" open, it is only used to fasten the muffler at the top.

Mark

Sure blows away a Hilti GP22 with , it's piddly little Kawasaki strimmer engineFirst one I have seen. Interesting.

Enter your email address to join: