I put a brand new auto oiler pump on my old Timberbear & opened up the adjustment screw 2 full turns & it still wouldn't oil.The manual oiler worked fine.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

McCulloch Chain Saws

- Thread starter Bruce Hopf

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I picked this one up for $20 tonight. Got home, dumped some fresh fuel in it and it fired up in 5 pulls. It has a very new looking Zama carb in it.

I just need to figure out why it won't oil. Neither the auto or manual oilers work.

Sent from my SM-G981U using Tapatalk

Sounds great, excellent save.

- Joined

- Jul 20, 2014

- Messages

- 1,882

- Reaction score

- 2,527

So the first reason it wouldn't oil...... I think the PO was using vegetable oil for bar and chain lube. It turned the consistency of snot in the tank and it smells like cooking oil. Also, anywhere there is oily sawdust caked on it is hard and waxy.

This is my first experience with this, I would rather deal with used crankcase oil.

It is torn down and the parts are soaking in my solvent tank.

Sent from my SM-G981U using Tapatalk

This is my first experience with this, I would rather deal with used crankcase oil.

It is torn down and the parts are soaking in my solvent tank.

Sent from my SM-G981U using Tapatalk

Here's a quick and dirty shop manual that was derived from a training presentation. Matter of fact and straightforward. Covers the oiler in a couple of different places. Only so many things can go wrong. First I've heard of pressure testing one, though. A good seal at the case is a must for starters. I do seem to recall reading somewhere that adjusting the auto oiler for too much flow can actually override its ability to supply any at all. Not sure how valid that is.

Attachments

I tried new gaskets and diaphragm and still no luck with either oiler. I do agree that opening the oiler too far seems to diminish the oil flow. I didn't try to open it any further but did close it down some and it oiled better.

I was lucky enough to get a couple of dump saws and one with low compression lent it's oil pump to the really nice . The other dump saw oils as well.

The really nice Eager Beaver i as gifted a while ago now has a good oiler on it.

It's not likely either will see much run time but nice to have one in the collection.

I was lucky enough to get a couple of dump saws and one with low compression lent it's oil pump to the really nice . The other dump saw oils as well.

The really nice Eager Beaver i as gifted a while ago now has a good oiler on it.

It's not likely either will see much run time but nice to have one in the collection.

Yeah canola oil is the new craze around here. I actually suggested it for cutting downed trees across one of our trout streams in a park. No other time would I recommend it.So the first reason it wouldn't oil...... I think the PO was using vegetable oil for bar and chain lube. It turned the consistency of snot in the tank and it smells like cooking oil. Also, anywhere there is oily sawdust caked on it is hard and waxy.

This is my first experience with this, I would rather deal with used crankcase oil.

It is torn down and the parts are soaking in my solvent tank.

Sent from my SM-G981U using Tapatalk

$59.99 ($0.40 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$225.16

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express Shipping ⭐⭐⭐⭐⭐

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$56.99 ($0.38 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$19.99 ($3.33 / Count)

Firewood Log Splitter 45mm+32mm + 4 Handles (Square + Round + Hex Shank + Small Hex) Wood Log Splitter Easy Splitter Detachable Drill Bit Heavy Duty Electric Drills Screw Cone Driver Removable

JianShiMoQinDianZiShangWuYouXianGongSi

I've worked on a lot of saws over the past few yrs.since I got involved with them & I've NEVER run into a situation where someone had used vegetable oil in the oiling system.I've never even run into a saw where they've used old motor oil.I guess I can call myself lucky.

It's a" Comifornication "thing, save the environment while murdering trees!I've worked on a lot of saws over the past few yrs.since I got involved with them & I've NEVER run into a situation where someone had used vegetable oil in the oiling system.I've never even run into a saw where they've used old motor oil.I guess I can call myself lucky.

I'm all about synthetic oils but bars and chains are way too expensive to gamble with for me and temperature ratings for cooking oil are way to low.

The 600 Series oilers operate very much like the 10 Series, in fact older ones used the same disc type check valve on the oil inlet. On this kind of pump, the only repair that might be required is to replace the diaphragm. You must use this type of diaphragm with the keyhole type slot with the older oil pumps.

The newer type oil pumps have a kind of built in check valve on the inlet side and use a different diaphragm with two holes.

If the oil pump won't work it is most likely because the small disc check valve has failed.

I was not able to reproduce a disc with the proper diameter and thickness in a hurry, but I am sure that will a little effort it would be possible to make a suitable disc for the later type oil pumps with the integral check valve. I did pull the automatic pump apart so you could see the check valve on the outlet end of the automatic portion of the oil pump.

You can test the automatic pump and outlet check valve by putting a drop of oil in the inlet hole and manually operating the piston. If the check valve it not stuck the oil will begin to come out of the discharge hole.

One last detail, the screw that secure the oil pump to the base adjacent to the oil inlet must have a sealing washer. I have used some generic fiber washers in place of the original, I could not make a O-ring work in this application.

Mark

The newer type oil pumps have a kind of built in check valve on the inlet side and use a different diaphragm with two holes.

If the oil pump won't work it is most likely because the small disc check valve has failed.

I was not able to reproduce a disc with the proper diameter and thickness in a hurry, but I am sure that will a little effort it would be possible to make a suitable disc for the later type oil pumps with the integral check valve. I did pull the automatic pump apart so you could see the check valve on the outlet end of the automatic portion of the oil pump.

You can test the automatic pump and outlet check valve by putting a drop of oil in the inlet hole and manually operating the piston. If the check valve it not stuck the oil will begin to come out of the discharge hole.

One last detail, the screw that secure the oil pump to the base adjacent to the oil inlet must have a sealing washer. I have used some generic fiber washers in place of the original, I could not make a O-ring work in this application.

Mark

When I got the new oil pump almost 3 yrs.ago I put it on the saw & didn't really have a chance to test it out because it was winter.In the spring I fired up the saw & called Bob J.to tell him that the oil pump wasn't working.He was the one who told me to open the screw up one full turn & try it again.When I told him it still wasn't oiling he told me to open it up another full turn.

Is the sealing washer for crank case pressure or oil sealing?The 600 Series oilers operate very much like the 10 Series, in fact older ones used the same disc type check valve on the oil inlet. On this kind of pump, the only repair that might be required is to replace the diaphragm. You must use this type of diaphragm with the keyhole type slot with the older oil pumps.

View attachment 861589

The newer type oil pumps have a kind of built in check valve on the inlet side and use a different diaphragm with two holes.

View attachment 861590

If the oil pump won't work it is most likely because the small disc check valve has failed.

View attachment 861591

I was not able to reproduce a disc with the proper diameter and thickness in a hurry, but I am sure that will a little effort it would be possible to make a suitable disc for the later type oil pumps with the integral check valve. I did pull the automatic pump apart so you could see the check valve on the outlet end of the automatic portion of the oil pump.

You can test the automatic pump and outlet check valve by putting a drop of oil in the inlet hole and manually operating the piston. If the check valve it not stuck the oil will begin to come out of the discharge hole.

One last detail, the screw that secure the oil pump to the base adjacent to the oil inlet must have a sealing washer. I have used some generic fiber washers in place of the original, I could not make a O-ring work in this application.

View attachment 861595

Mark

That is to seal the hole since it is connected to the oil inlet passage.

Mark

Mark

The adjusting screw bears against the plastic sleeve to control the stroke of the piston. Once you turn it so far open the stroke is at maximum even though the screw may turn further. Sometimes if the piston is a little sticky, turning the screw to reduce the flow will move it enough to free it up and start it working again.

Mark

Mark

I've worked on a lot of saws over the past few yrs.since I got involved with them & I've NEVER run into a situation where someone had used vegetable oil in the oiling system.I've never even run into a saw where they've used old motor oil.I guess I can call myself lucky.

You certainly are lucky man. Ive had three with waste oil. My first 7-10 was the worst and required a full strip down to the block to clean the last of it off. Yuck

This came from the guy who has a drum full of waste oil beside his log pile for dunking the bar in when running saws with dead oilers lol. This is no joke.

The poor 7-10 in question also had waste oil in the fuel

I had a red saw that came to me in really nice condition except the oiling system was full of something like concrete. None in the lines but everything else was full of that crap. no idea what they were running for oil.

I am still cleaning up saws in preparation for moving them to the new museum and workshop building and decided to tackle this 10-10. I thought it would be nice to have the full wrap handle bars on display and I already have a RH start set up over there. When I took it apart it was dirty, the fuel tank was leaking, the fuel cap was leaking, and it died while I was trying to tune it and lost spark. Upon disassembly I found it had been fit with a chip, and that the wire had come loose. I decided to switch it back to points.

The short brake clutch cover had a few deficiencies already so I didn't mind modifying it to fit the full wrap bar.

Mark

The short brake clutch cover had a few deficiencies already so I didn't mind modifying it to fit the full wrap bar.

Mark

Here is my latest project. My neighbor came over with it and told me he had finally gotten into cleaning out one of his sheds and found this and gave it to me. I did not get any before pictures, but I can tell you it was extremely dirty. I put some fuel into the carb and it fired, but quit after it ran out of the fuel I put in it. I had blew it out with compressed air, but when it started it blew out a couple hand fulls of stinkbugs and remains and nest. It was ugly. I pulled it apart and cleaned it and cleaned and rebuilt the carb and it runs like a clock. In the pictures it is missing the brake handle. I have got to find the screw that goes in there, it was missing when I got it.

The stinkbugs I got out of it. A bunch of live ones that met there death due to a can of WD-40 and a lighter.

I have not put it to wood, but it sounds good.

My other project, 1988 Honda Goldwing that has been setting for 15+ years. Had to clean fuel system and rebuild carbs. Chase a couple electrical gremlins and a few other things. Got it running and am now putting it back together. This is how a smooth engine runs. That is a nickel on the valve cover. Used to do this at bars and bet for beers. Won many beers doing this.

Brian

View attachment IMG_0867.MOV

The stinkbugs I got out of it. A bunch of live ones that met there death due to a can of WD-40 and a lighter.

I have not put it to wood, but it sounds good.

My other project, 1988 Honda Goldwing that has been setting for 15+ years. Had to clean fuel system and rebuild carbs. Chase a couple electrical gremlins and a few other things. Got it running and am now putting it back together. This is how a smooth engine runs. That is a nickel on the valve cover. Used to do this at bars and bet for beers. Won many beers doing this.

Brian

View attachment IMG_0867.MOV

I would also bet on that being a 640. Although not as common it may also be a 1-85 or 1-86. Mark will probably be able to give better insight.MAC EXPERTS WANTED NAME THAT OL' MAC Thanks guys. My guess is a mac 640 gear drive. What's your thoughts?View attachment 861616View attachment 861617View attachment 861618View attachment 861619View attachment 861620

Sent from my SM-N970U using Tapatalk

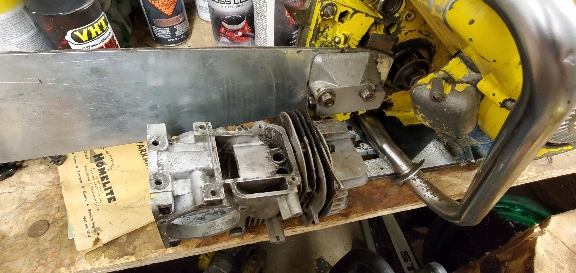

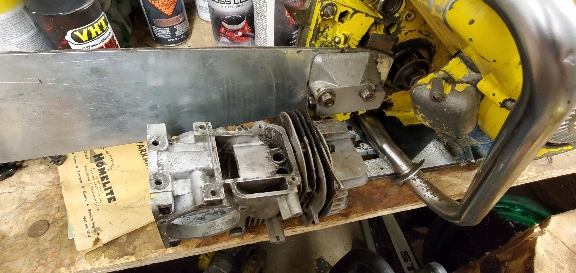

Getting ready to bore this super 55 cylinder and do some port work. Although I know what I want to do I really would like to pick the brain of someone who has some decent experience modifying and porting old Mac cylinders.

Sent from my SM-N970U using Tapatalk

Sent from my SM-N970U using Tapatalk

Similar threads

Want to Sell

Vintage Collection Liquidation

- Replies

- 2

- Views

- 1K