HeRoze

Addicted to ArboristSite

These are the wraps, the half wraps will replace them.

... and there is the template for some dogs. cool.

These are the wraps, the half wraps will replace them.

that is a beast - - I think my testosterone went up a couple of clicks just looking at the pics.well changed my mind on the next yellow beast to get running. haven't done anything to this one because it's so damn big and heavy. the bar and chain will give you a hernia . ----

Is it dull? Does it 4-stroke out of the cut? Is that the right bar, maybe it needs the spacer for the bar plates? That saw sounds like its bogged down before you even cut anything, especially in the last few seconds of the video when your bliping the throttle. Not making the RMP is should be, that was painfully slow on that last cut and it was Alder. Right about the 1:00 mark, you even look at the saw like somethings wrong.

I say that because it looked like you were struggling with it, close quarters and an angled cut will do it for sure. Watching again I can see it was angled. I'm watching because i have a CP70 I'm about to dig into. Thanks for posting the video!

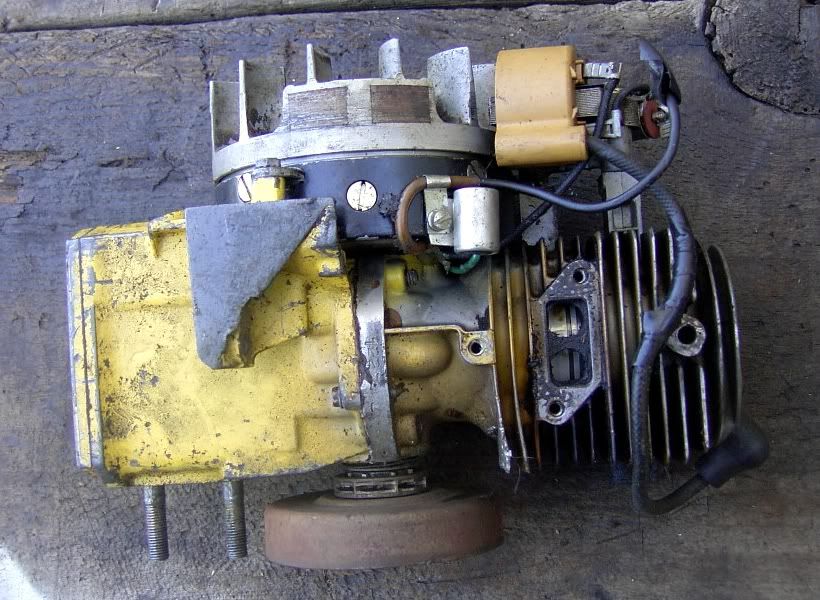

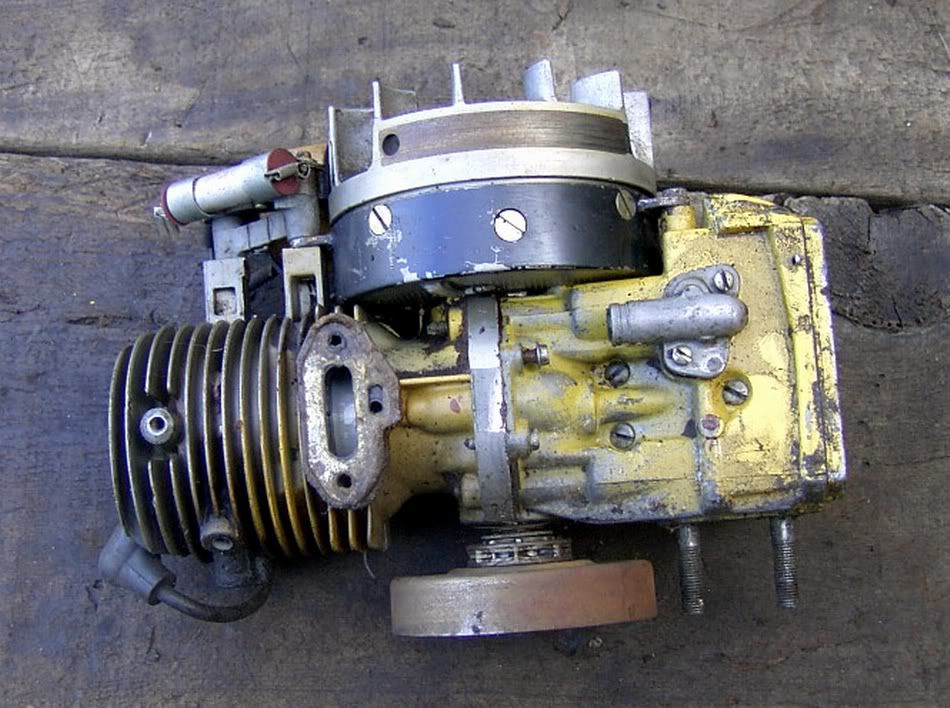

Been spending some time working on a CP70 I picked up last weekend.

There were a few issues that I have found with it, some were fixed and some waiting to be fixed. First off, the intake boot was completely fried, which someone tried to JB Weld it back together, causing the epoxy to run down into the intake block. This needed cleaned up.

The intake boot in the IPL was listed as Part Number 69647. I took a chance on part number 213987/215247 and it was successful. The boot was a direct bolt on, although the lower part of the boot in the IPL shows no "flanges" in the IPL. It mated up to all mounting surfaces just fine.

The crankcase had certainly been apart on this saw previously, and was resealed with orange silicone sealant. In a way I was glad for this, because I found a few little bits of the epoxy down in the crackcase and transfers.

This is a thin ring/domed piston saw. It seems to make good power although I certainly do not have it tuned in right just yet.

Anti-vibe is on par with other macs of this variety, such as the SP80, SP81, PM800, 805 and 850.

Although the motor is supposedly very similar to other 4.3 cubic inch Macs the muffler that is on it produces a much different sound, which is somewhat more similar to my J-red 49sp, as opposed to other 4.3 cubic inch Macs that I have. I think I'm going to try and find a way to remedy this, as I prefer the loud, ear piercing sound.

It seemed to produce good torque, but I have not had the thing in ideal conditions, just a quick couple of passes at some spruce I had laying out there in the pile. More to come, for sure.

It has a few small issues that need sorted out including the kill switch, and some hardware issues.

And a Video that can be seen by clocking the following link....

This is one of my latest projects. I didn't have to do much to it but put in a new air filter and rebuild the battery pack. The filter was oily and plugged so the dufus owner cut some "windows" out of the felt so it could breath through the wire screen. The original Nicad cells were rated at 1 amp/hr and I replaced them with 2.1 amp/hr batteries so it really spins over. The saw doesn't seem to charge, I haven't had time to do any trouble shooting to see if it's the resistor or voltage regulator. It will start many times on a single charge so it's not a real high priority right now. If it's the voltage regulator, it's going to be like hen's teeth to find. Thanks to Mark H for the electric start shop manual!

Jim

that 10-10E looks good, i'm jealous. here is my 3-10E, its not as good of a video as yours though.

McCulloch 3-10E - YouTube