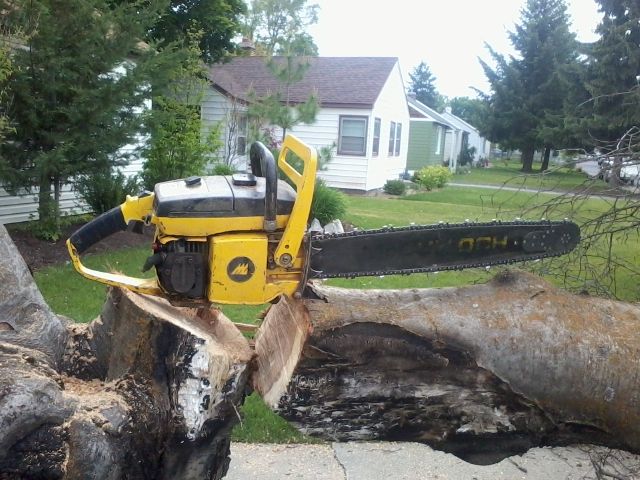

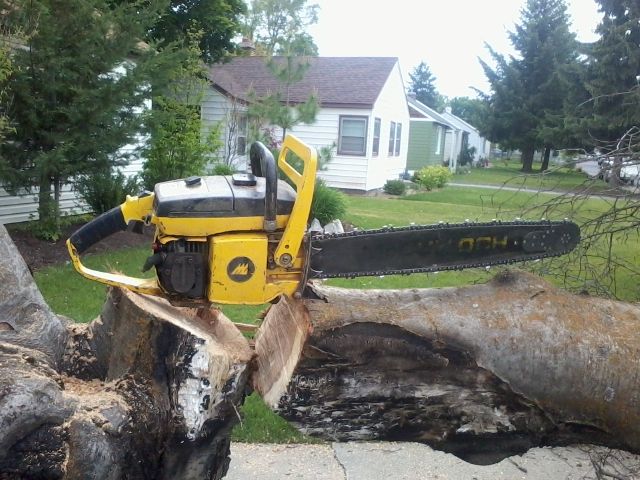

stretched the legs on the 82cc CP70 today, I did a removal of a mountain ash. The saw preformed flawlessly as usual for a 10 series.

Sweet, We're going to have to start calling

you Mcculloch Jim.

Lee

stretched the legs on the 82cc CP70 today, I did a removal of a mountain ash. The saw preformed flawlessly as usual for a 10 series.

Got the sp125 out for a little excercise the other day to cut a tree for a friend. Will be going back to drop another decent size tree and haul to the sawmill for him soon. I sure like that 125.

Jeff

Looks like everyone has been having some fun. I finally got home tonight, will have to try and get some photos of the surprises that arrived while I was away posted up tomorrow.

Mark

I"m thinking of building a couple saws later this summer, an SP-105 & SP-125. I have 4 or 5 completely apart SP's that I robbed a part here or there about 10 years ago to build an SP-125C. Going through the boxes of parts, I noticed that I have 2 cylinders which had a slight amount of surface rust (cylinders have been oiled again) and 2 cylinders did not (one completely junk and the other iffy at best).

Would it be fair to say the one with rust are cast iron cylinders? What else could I use to determine which is which? Is there a part number somewhere of the cylinder? I didn't see one, but I could have looked right over it......

Another question, what color schemes have you seen or own? The saw i built (and use ~ not a shelf queen) has yellow fuel tank and bottom brace and black engine. I have one black fuel tank (rest yellow) which I think was the 105. Just looking for ideas.....

Lastly, anyone come up with the color powder coat color to match the mac's?

bob

I pulled the Italian titan 50 out to do some precision deck post adjustments. Pulled and pulled. No spark whatsoever? it ran when i parked it.

Brian

A magnet will verify wether its steel or chrome in the bore

McBob

i used another type of alcohol while building mine but it tastes better than rubbing alcohol and come from the hills of TN.

i can PM you the seller that i get my powder from. here are the pics of the finished saw. on the muffler, i used a high temp silver powder coat. it was very durable and didn't burn or peel.

as a side note, the temp from the oven may have led to my fuel leaks in the two piece fuel tank seam.

That would be too easy. Honestly, I thought they were steel liners with a chrome layer over it.

George Di ckel (put the letters together) # 12 :msp_confused: since when is a whisky name considered "bad" :msp_confused:

Please do. At least it will give me a start. Granted i have to: finish the re-roofing the garage, complete my tear-down and restoration of a Lincoln Idealarc 250/250 welder and tray and get to my 1948 Deere B to run again (lost spark). And then get the 660 and SP-70 running. And after that, it is Super-Pro time (I think).....

What temp were you at?

i've got a DE50 that will run but has an air leak somewhere causing it to run lean. after i noticed it running lean, i put it up and haven't used it again so the P&C are still in good shape. its the same as you're titan 50 so if you need a parts saw, just PM me.

also, i've used a 10-10s coil on a titan 620. so, it may be possible to do something like that on a titan 50 if you can't get a original coil.

joey

Do coils just go bad sitting on a shelf? it ran great when i last set it down. Wierd

Brian