Ok,,,is the crank seal and bearing going to present any problems coming out ?

how about installation of bearing and seal and housing ??

i put arrows on your pic of the holes to use for puller,correct ?

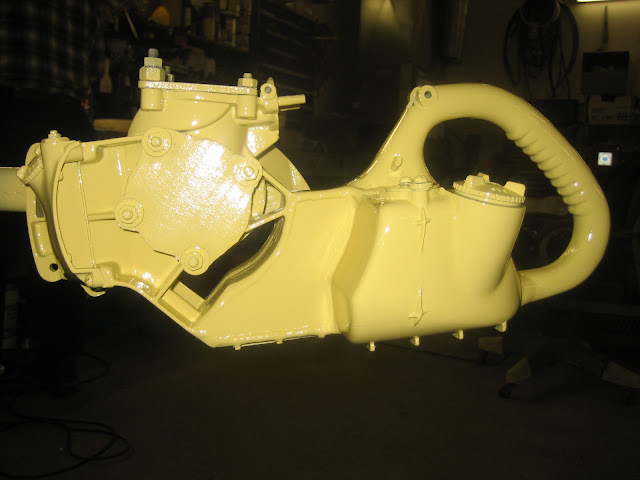

i was only wanting to get this going to hear it run and check it out before making it a bigger project later..after this much teardown it dont look like much more and it would be ready for a paint job

i think what i may do now is save all this info,put saw back together so i dont lose any parts and make it a winter project when i can take more time and be able to dry paint over the woodstove..that is how i seem to get my paint to last the best..

So,info on paint and prep is also needed.. I'm sure the other guys watching this will be interested in anything you can give us...

bearing installation also after housing removal,,i miss anything ?

Ron..

Yes you can make a simple puller and use machine screws to connect to those two bosses and the puller bolt to the crank. The seal and bearing will come off with the fan housing, no damage usually. To install the four studs and the nuts will pull the fan housing back in place. Don`t heat the fan housing when putting it back together, it has to slip back inside the main housing , you don`t want it swelled. It is not a really difficult job to get to where you want to go , the first time around may seem like it but after getting the first one done it becomes old hat. If you missed anything else just give me a shout.

Pioneerguy600