Jerry,

When you rebuilt that NU-17, did you ever check the compression? I got part of a service manual for that saw(thanks Lawrence) and it listed the compression at between 90-105psi. I wondered if that was a mis-print?

The NU17 has around 130-135 lbs currently,it would be very hard to start and have little power with 90-105 comp.

Pioneerguy600

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pioneer chainsaws

- Thread starter WesternSaw

- Start date

-

- Tags

- operator manual

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

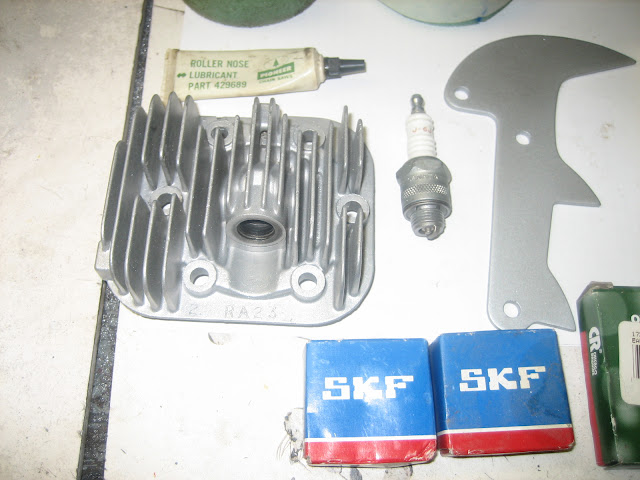

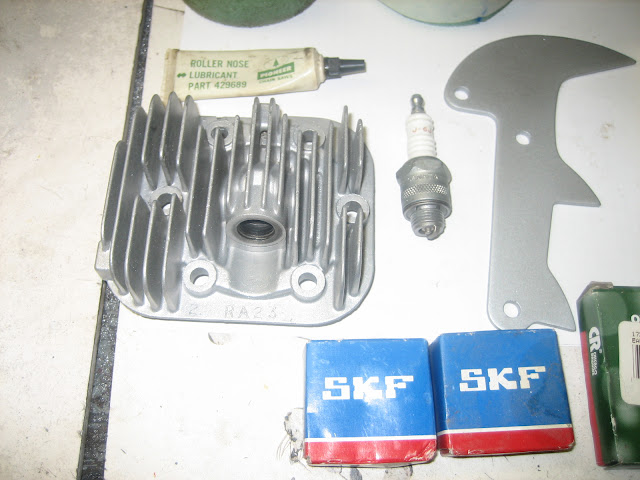

A few more picts of what I will be using to put the RA back together with.

propliner

ArboristSite Guru

1073

It's not normal but I think it may have been caused by carbon buildup at one time. Using too rich an oil mixture is usually the culprit and I've read that too much oil is worse than too little... for this very reason.

The compression is not dependent on the fit above the rings and if the cylinder hasn't been scored then there is probably no serious damage. Be careful of the mixture and check occasionally for carbon buildup.

The piston in my 1073 is scored above the rings. The cylinder wall looks good and the piston below the rings looks good. Is this normal for this saw?

It's not normal but I think it may have been caused by carbon buildup at one time. Using too rich an oil mixture is usually the culprit and I've read that too much oil is worse than too little... for this very reason.

The compression is not dependent on the fit above the rings and if the cylinder hasn't been scored then there is probably no serious damage. Be careful of the mixture and check occasionally for carbon buildup.

A few more picts of what I will be using to put the RA back together with.

Jerry, you're just bragging now.

Jerry, you're just bragging now.

Thanks Jacob, just thought some of the Pioneer guy`s would like to know the rebuild details on this one. Of all the rebuilds that I have done over the years this is the first one that I have documented with picts of every step, I have 66 picts stored on this one now. Usually only have taken before and after picts but had many PM`s asking for more detailed rebuilds.

Pioneerguy600

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$225.16

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express Shipping ⭐⭐⭐⭐⭐

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$59.99 ($0.40 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$19.99 ($3.33 / Count)

Firewood Log Splitter 45mm+32mm + 4 Handles (Square + Round + Hex Shank + Small Hex) Wood Log Splitter Easy Splitter Detachable Drill Bit Heavy Duty Electric Drills Screw Cone Driver Removable

JianShiMoQinDianZiShangWuYouXianGongSi

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$56.99 ($0.38 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

no longer collecting

ArboristSite Operative

Speaking about rebuilt, i have a nice project to work on . Last week i found myself a nice Pioneer P35 .

It will be quite a challenge since this saw does not exist and there are no parts for it ...they have to be made....Quite a unique saw with lots of unknown.

PS: If you know anybody that has one let me know since i am doing the history and would like to get in contact with an owner.

I am mainly looking for a copy of the “said so” letter that was signed by the employees….and some testimonies….they are only a handful and I am not sure on how much are still alive to this day.

The saw would be 32 years old when the test run stopped……assuming that the engineers that worked on the project were around 30 at the time……..they would be over 60 to this day and the closure of the plant plus the failure is certainly something that they wish not to remember…

Alain,

It is posted now on my web site.

Alain,

It will be quite a challenge since this saw does not exist and there are no parts for it ...they have to be made....Quite a unique saw with lots of unknown.

PS: If you know anybody that has one let me know since i am doing the history and would like to get in contact with an owner.

I am mainly looking for a copy of the “said so” letter that was signed by the employees….and some testimonies….they are only a handful and I am not sure on how much are still alive to this day.

The saw would be 32 years old when the test run stopped……assuming that the engineers that worked on the project were around 30 at the time……..they would be over 60 to this day and the closure of the plant plus the failure is certainly something that they wish not to remember…

Alain,

It is posted now on my web site.

Alain,

Last edited:

crane

Addicted to ArboristSite

I would have to agree with you Jerry, just struck me as odd. Either I'm reading it wrong, or it is a misprint.Jerry,

When you rebuilt that NU-17, did you ever check the compression? I got part of a service manual for that saw(thanks Lawrence) and it listed the compression at between 90-105psi. I wondered if that was a mis-print?

The NU17 has around 130-135 lbs currently,it would be very hard to start and have little power with 90-105 comp.

Pioneerguy600

When the rings are in, I'll shoot for 140psi range. Thanks

propliner

ArboristSite Guru

P35

Boy, what I wouldn't give for one of those!

Any idea how many cc's the P35 was?

Last week i found myself a nice Pioneer P35 .

Boy, what I wouldn't give for one of those!

Any idea how many cc's the P35 was?

no longer collecting

ArboristSite Operative

Boy, what I wouldn't give for one of those!

Any idea how many cc's the P35 was?

Nop...Since there was never an IPL or operator manual for this saw.

I think i will make a new post ..to get more attention...

Dont want to screw this one.....

Alain,

FELLNORTH

ArboristSite Operative

Some of the new parts going back into this saw.

More picts tomorrow evening.

Pioneerguy600

where are you getting your parts, i scored an IEL RA this week end and want to do the same quality job as you. the RA is complete but filthy.

nice job.

do you have a paint code?

thank for the pics.

tyler

I would have to agree with you Jerry, just struck me as odd. Either I'm reading it wrong, or it is a misprint.

When the rings are in, I'll shoot for 140psi range. Thanks

I pulled my copy of that manual and read the same page as you have posted, does not seem correct to me either. If you go to page 32 that covers the 600 and look under cylinder,piston,rings and pin it says the comp should be 125-145 for the 600 series saws. The NU 17 and the 600 series saws use the same piston and rings so I would think that they both should have similar compression. It must be a mis print , just goes to show that you can`t believe everything that is printed.

Pioneerguy600

where are you getting your parts, i scored an IEL RA this week end and want to do the same quality job as you. the RA is complete but filthy.

nice job.

do you have a paint code?

thank for the pics.

tyler

FELLNORTH;

I got a lot of my parts years ago when I bought out a Pioneer dealers left over stock when he retired, I have been involved with Pioneer saws since 1957 when my father bought our first new saw, that was a Pioneer 600, the first year they were made and we got a very early production model #( 40 ) . Paint for the IEL`s and Pioneers was not a standardized color and there is many shades on the same models that varied somewhat throughout the model run, I take in a part to our paint supplier and he will closely match it to the original. I own over 40 of the IEL`s and Pioneer 600 series and no two are the same color so I just try to match what is on them when I get them if the paint is the original and was not repainted by some redneck. LOL.

I bought one 600 once that was painted " red " , man that was an ugly saw.

Pioneerguy600

FELLNORTH

ArboristSite Operative

thanks for the info, can you tell me what the best way to remove the flywheel is?

i dont want to use the old hold it up and beat on it trick, but there is no place to grab with a puller.

thanx again.

i dont want to use the old hold it up and beat on it trick, but there is no place to grab with a puller.

thanx again.

tallfarmboy

ArboristSite Guru

Howdy all...

Working on a Pioneer 400 that I purchased for a song here locally.

Saw has no spark...

1. Are points located under the flywheel?

2. Is the flywheel nut LH thread?

3. Are there any sources for aftermarket ignition parts? This saw was only made 2 years so I'm guessing that I am going to be SOL.

4. Does anyone have a service manual or IPL for this saw (Pioneer 400)?

Thank you!

TFB

EDIT: Flywheel nut is off... reverse thread... Any tricks to removing flywheel short of fabricating a puller?

Thank you!

Working on a Pioneer 400 that I purchased for a song here locally.

Saw has no spark...

1. Are points located under the flywheel?

2. Is the flywheel nut LH thread?

3. Are there any sources for aftermarket ignition parts? This saw was only made 2 years so I'm guessing that I am going to be SOL.

4. Does anyone have a service manual or IPL for this saw (Pioneer 400)?

Thank you!

TFB

EDIT: Flywheel nut is off... reverse thread... Any tricks to removing flywheel short of fabricating a puller?

Thank you!

Last edited:

WesternSaw

Addicted to ArboristSite

tallfarmboy

If you can PM me your email I could scan and send.I think I have something you could use.

Lawrence

If you can PM me your email I could scan and send.I think I have something you could use.

Lawrence

briantutt

Addicted to ArboristSite

1073 Bar Stud

Still looking for pointers for removing one of the bar mount studs on a 1073. Anyone done this before? Can I weld on a nut and use that? Also, Does the piece the bolt goes through (that requires me to remove the clutch to remove) have to come off first?

Still looking for pointers for removing one of the bar mount studs on a 1073. Anyone done this before? Can I weld on a nut and use that? Also, Does the piece the bolt goes through (that requires me to remove the clutch to remove) have to come off first?

WesternSaw

Addicted to ArboristSite

Best answered by more mechanicaly inclined than myself

Hi Brian

I think that pioneerguy600,propliner,pioneerman,crane,JacobJ,and all the other gurus would be the go to guys for this

Lawrence

Hi Brian

I think that pioneerguy600,propliner,pioneerman,crane,JacobJ,and all the other gurus would be the go to guys for this

Lawrence

Similar threads

- Locked

- Replies

- 36

- Views

- 6K

- Replies

- 15

- Views

- 2K

- Replies

- 10

- Views

- 5K