That definitely makes a difference. Subtract .75HP from the ported saw, and I'm still one happy saw builder!I did a little investigating. I found an engine tuner calculator that suggests the majority of the stock 461 Hp increase was probably due to the the colder drier air that the saw was consuming now compared to the last stock 461 test I did back in August. Temperature and humidity make a significant Hp change. This is why I always do a test against a base line saw at the same time as the modded saw.

http://wahiduddin.net/calc/calc_hp.htm

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Snellerized MS461 on the dyno

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I did a little investigating. I found an engine tuner calculator that suggests the majority of the stock 461 Hp increase was probably due to the the colder drier air that the saw was consuming now compared to the last stock 461 test I did back in August. Temperature and humidity make a significant Hp change. This is why I always do a test against a base line saw at the same time as the modded saw.

http://wahiduddin.net/calc/calc_hp.htm

I was curious about that Chad. Do you run the dyno outside?

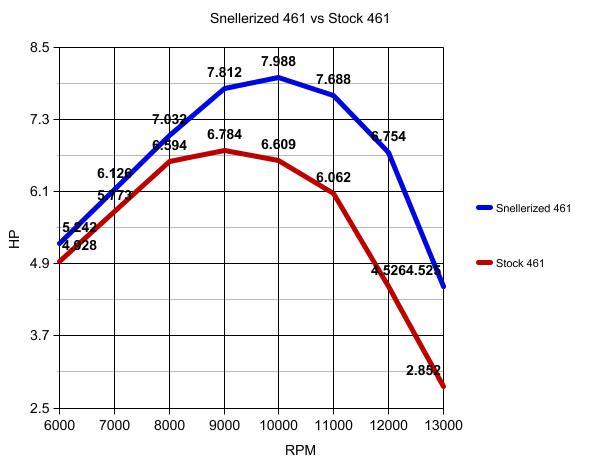

For all of you that run your 12000 rpm in the cut take a look what happens to the hp at 12000 rpm. Steve

It's still making more HP than stock max HP. This saw should cut fastest at 10,000. I find that most saws perform best with a moderately heavy load, but shy of bogging it.For all of you that run your 12000 rpm in the cut take a look what happens to the hp at 12000 rpm. Steve

chadihman

Addicted to ArboristSite

Most of the time yes. The shop I test in is huge and we have exhaust drop hoses but I find it really hard to capture the exhaust especially on a dual port muffler. I roll the dyno outside the door because the shop gets uncomfortably smokey quickly. I do a lot of cutting in the summertime then my saws sit for awhile till its cold and the ground is frozen. I feel the need to usually retune when its cold. Cold air is more dense so the saw runs leaner when its cold. I've had ported saws that felt like they could have had a larger carb when running it in super cold weather but they run fine when its warm.I was curious about that Chad. Do you run the dyno outside?

$142.39

$179.99

ROPE Logic Ultra Ring Sling #3 Riggling Thimble 3/4" Tenex x 6' (40203)

Greener-Garden

$15.95 ($15.95 / Count)

$17.99 ($17.99 / Count)

Fiskars Pole Saw Blade Replacement for Fiskars Pruning Saws and Tree Pruners, 15 Inch Saw Blade with Woodzig Chainsaw-Style Saw Tooth Design

OKB85

$79.99

$89.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$19.99 ($3.33 / Count)

Firewood Log Splitter 45mm+32mm + 4 Handles (Square + Round + Hex Shank + Small Hex) Wood Log Splitter Easy Splitter Detachable Drill Bit Heavy Duty Electric Drills Screw Cone Driver Removable

JianShiMoQinDianZiShangWuYouXianGongSi

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$35.99

$39.99

Wood Kindling Splitter - The Firewood Kindling Tool for Wood Stove Fireplace and Fire Pit

UniExtra

l suppose if your comparing saws it is quite important to do them together rather than comparing testing from another day. My cars always run better at night, cooler air with more oxygen in it. lt makes quite a difference compared to a hot humid day. Great tuning tool!! Great port job!I did a little investigating. I found an engine tuner calculator that suggests the majority of the stock 461 Hp increase was probably due to the the colder drier air that the saw was consuming now compared to the last stock 461 test I did back in August. Temperature and humidity make a significant Hp change. This is why I always do a test against a base line saw at the same time as the modded saw.

http://wahiduddin.net/calc/calc_hp.htm

old-cat

Fir Man

If a rev limiting coil stops the rpms at just above 13,000 rpms, then I fail to see any reason not to use it.

Was this run outdoors?Most of the time yes. The shop I test in is huge and we have exhaust drop hoses but I find it really hard to capture the exhaust especially on a dual port muffler. I roll the dyno outside the door because the shop gets uncomfortably smokey quickly. I do a lot of cutting in the summertime then my saws sit for awhile till its cold and the ground is frozen. I feel the need to usually retune when its cold. Cold air is more dense so the saw runs leaner when its cold. I've had ported saws that felt like they could have had a larger carb when running it in super cold weather but they run fine when its warm.

It's much easier to hear the tune with an unlimited coil. This saw tunes well above the rev limiter.If a rev limiting coil stops the rpms at just above 13,000 rpms, then I fail to see any reason not to use it.

Ron660

Addicted to ArboristSite

That's a lot of deviation in stock saws tested. Best I remember, the earlier stock 461 tested was 5.9HP and this one is 6.7HP?I did a little investigating. I found an engine tuner calculator that suggests the majority of the stock 461 Hp increase was probably due to the the colder drier air that the saw was consuming now compared to the last stock 461 test I did back in August. Temperature and humidity make a significant Hp change. This is why I always do a test against a base line saw at the same time as the modded saw.

http://wahiduddin.net/calc/calc_hp.htm

old-cat

Fir Man

I tune my saws in the cut by sound

chadihman

Addicted to ArboristSite

49.2% gain at 12000 rpms This saw will pull really well in wood with the right sprocket and chain combo from 9000-11000 rpms. It'll run better at any rpm really. The saw mounted tach is nice Brad. Nice and small with a clean look. The dyno results and the saw mounted tach will tell you where its best cutting speed is.

This saw will pull really well in wood with the right sprocket and chain combo from 9000-11000 rpms. It'll run better at any rpm really. The saw mounted tach is nice Brad. Nice and small with a clean look. The dyno results and the saw mounted tach will tell you where its best cutting speed is.

I want one…& not the dynoI finally bit the bullet and sent a saw to Chad to run on the dyno. This particular saw was built the same as all of my 461s, not knowing it was going to go on the dyno. Also, this saw is not nearly broken in, as it's still on only is first or second tank of fuel.

This graph does a great job of giving a visual representation of my build style, and why I build like I do. I talk a lot about demanding both RPMs and torque. If a saw doesn't have both, I'm not happy with the build. Notice how the ported saw makes as much or more HP than the max of the stock saw from about 7,500-12,000 RPMs. HP climbs earlier than the stock saw but at the same rate/curve. Once the stock saw maxes out, the ported saw just keeps climbing. Once it peaks, there's no abrupt fall off, and it tapers off nicely. It's making 6+ HP from <7,000 all the way up to almost 12,500.

Even more surprising than the results of my ported saw, are the results of the stock saw. This is the same saw that Chad ran on his dyno before, only this time, it's making 3/4 more HP. Since then, this saw has seen a lot of run time with a 36" bar, so is fully broken in. The same testing methodology was used. This really surprises me. I would have never guessed it would be that much. This would suggest that the ported saw should easily end up at 8.5+HP. I'll take that!

A couple details about how I build a 461. This saw has a .035" popup, resulting in 180-190 PSI compression. It's been several months since I built this saw, so I don't recall exactly what it was. I find that the 461 runs best with lots of intake duration and set the intake port timing at 85°. I've also found that it likes short blowdown, so have that set at 16°. I've tested other configurations, and this is where I find the 461 runs best. This saw is wearing a 046 coil and timing has been advanced about 6°.

HuskStihl

Chairin'em for the sound

I'm back to the stock coil in my only limited ported saw. I like the unlimited coils for tuning to get the maximum performance, but these days, I'm running most stuff pretty rich, so I'm 4-stroking before bumping the limiterI tune my saws in the cut by sound

I thought so as well. I haven't punched numbers into the calculator to see how much weather affects the numbers. I do know that forum members talk about how much difference break-in can make. I still thought that was a lot. Like said earlier though, take off .75 HP and I'd still be happy.That's a lot of deviation in stock saws tested. Best I remember, the earlier stock 461 tested was 5.9HP and this one is 6.7HP?

Did you find it to be accurate? I thought it seemed kind of inconsistent and was scared to trust it.The saw mounted tach is nice Brad. Nice and small with a clean look. The dyno results and the saw mounted tach will tell you where its best cutting speed is.

Ron660

Addicted to ArboristSite

I concur. But if you take off 0.75 HP from the stock saw you also have to lower the ported saw result the same to a max of 7.2. No matter, these are good results.I thought so as well. I haven't punched numbers into the calculator to see how much weather affects the numbers. I do know that forum members talk about how much difference break-in can make. I still thought that was a lot. Like said earlier though, take off .75 HP and I'd still be happy.

I concur. However, I have to believe the dyno is accurate, based on prior performance. I don't think he has changed anything recently. The question to me is if the difference is weather, break-in, or possibly tune. Chad, do you recall of you had the stock saw tuned to the same RPMs both times.I concur. But if you take off 0.75 HP from the stock saw you also have to lower the ported saw result the same to a max of 7.2. No matter, these are good results.

HuskStihl

Chairin'em for the sound

This is a fairly simple dyno, and SAE corrections may not be as applicable to small two strokes. Basically, you are going to have to look at percentage of improvement vs stock rather than absolute numbers. This dyno is perfect for seeing how porting changes affect the power band, but really bad for pissing matches. Your saw made a really nice gain over stock, the absolute number is meaningless

Similar threads

- Replies

- 1

- Views

- 553