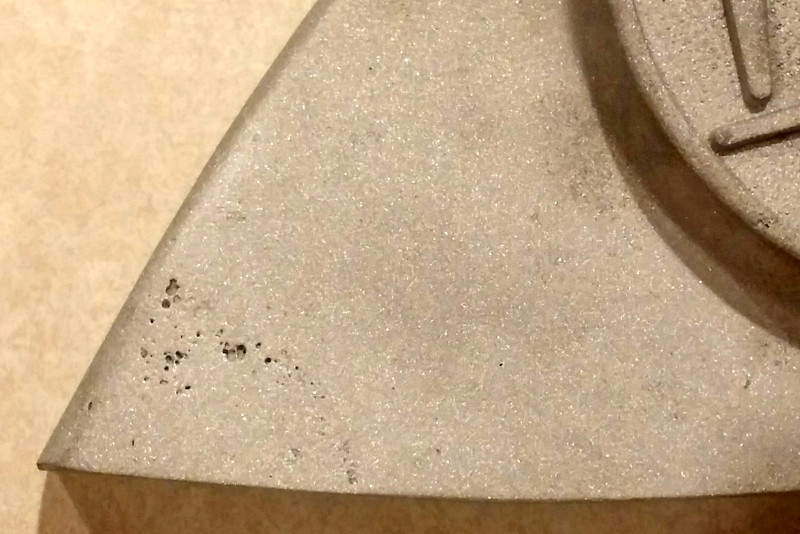

Here it is after welding/before filling. Shaun will be posting a video in the next couple of days. That will be pretty cool.

I have. I apply it with a razor blade, at Mike's suggestion, and scrape filler over the hole in every direction. I guess it's viscous enough that it doesn't want to go in those tiniest holes and displace the air.That looks great Shawn does good work on everything he puts his hand to.

Brad, have to tried pushing the filler in the pits with your finger?

I have. I apply it with a razor blade, at Mike's suggestion, and scrape filler over the hole in every direction. I guess it's viscous enough that it doesn't want to go in those tiniest holes and displace the air.

I have great confidence in JBWeld. One thing I love about this filler Mike sent me, is that I can throw it in a toaster oven at 225°F for 25 minutes and it's rock hard, ready to sand.Wow that looks great. Good job Shaun. For those pin holes I use JB weld a lot the time.

I'm not sure JB Weld, or even Devcon would work under powder coat. The baking might be too hot, even if it would allow adhesion.

ive tried jb weld it holds up under the heat but it wont allow adhesion of powder it must have a oil in it it results in fisheye like marks in powder when cured !