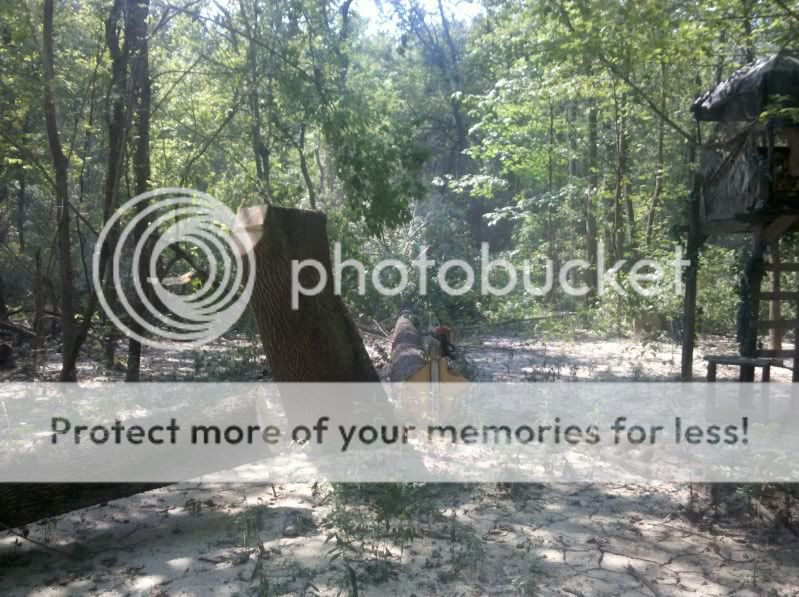

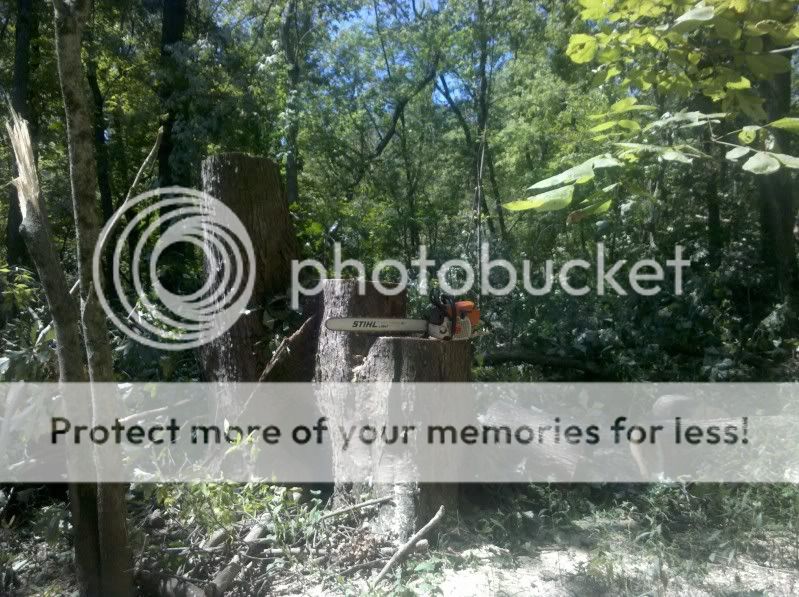

Nice pics and vids there Sam,i see your giving them Stihl light bars a woork at the refueling area.

I think your PM box is full.

Andrew

Andrew, I cleaned some more messages out. (the saw is headed toward Terry now).

As to the Lite bars, I am treating them just like the regular bars. That said, I do or did have one issue with one of them, but I don't know if it was due to handling abuse, heat or what but the aluminum panel has ripples in it, and I'm not sure how it happened. I'm going to talk with me dealer and see about it. That said it could very well, be due to the way I treat bars and if that is the case I don't fault the bar at all, as I use them as baseball bats, LOL. I'm not sure when or how it happened, I was cutting and noticed that it "slowed" down a bit, so I checked the chain, it wasn't really dull, but I sharpened it and thats when I noticed these two ripples. I did get the bar stuck in a tree and it smashed it pretty hard going over, so I don't know it that did it or what? The bars have equal cutting time and similar abuse on them and the other one is fine, so I think it was that "bad" pinch with a pretty good smash awards that rippled this bar. I'll take some photos of it. All I have to do is sand the ripples down and proceed with normal use, as the rails are straight and it tracks straight, so don't know why or how it happened.

That said .................... I can say this I will probably never cut much professionally without a 28" Lite bar on any of my saws, unless I am using a shorter bar for bucking up or something, these things are amazing. By comparison or simply "feel" its like holding only the powerhead and no bar has been mounted on it yet, most any 70cc saw it going to feel like a toy with it on, LOL. I do more over head cutting now than I ever did as a result, LOL. I'd rather cut with the 28" Lite bar than with a regular 20" bar, even if its just something little, they are that nice.

I don't know that a regular homeowner type human would ever see much benefit "financially" from the use of a Lite bar, but the "professional" or someone who has the opportunity to complete more work and get paid more as a result should really see and improvement in production from it.

As to the refueling position, the bars don't seem to mind that minor stuff, LOL.

Sam

"really, theres people out there who cant do that successfully?" LOL!!

"really, theres people out there who cant do that successfully?" LOL!!