opps!!Dang it, something bad happened in here:

Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stihl 028 AV Super Rebuild Project

- Thread starter briantutt

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

brandonstc6

Addicted to ArboristSite

Do any of those lines catch your fingernail?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

brandonstc6

Addicted to ArboristSite

I do have a good cylinder for an 028 super. I've already robbed a few parts off of the saw I guess I could take the cylinder too. I have another locked up 028 super with a good cylinder that I could take off too. If you are interested

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$17.99

$19.99

Extendable Pole Saw Branch Trimmer Pruner Head for Tree Trimming Pruning

FENGLICNSAOMV

$29.98

ONETIAN Welding Pants, Chainsaw Pants, Welder Chaps, Safety Leg Protection (35 in) Black

ONETIAN PROTECTION

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$194.26

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express-Shipping-24hr ✅

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

brandonstc6

Addicted to ArboristSite

Your welcome. You did say you have a new piston right?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

briantutt

Addicted to ArboristSite

yes new meteor brandYour welcome. You did say you have a new piston right?

Sent from my iPhone using Tapatalk

Brian

brandonstc6

Addicted to ArboristSite

Good deal. If you can use OEM clips for piston pin. You can probably still get them from a good stihl dealer?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I have used the mastermind technique a few times to clean up a cylinder and quite surprised how well it works...good luck on your 28 there a nice one to have around!

LegDeLimber

Addicted to ArboristSite

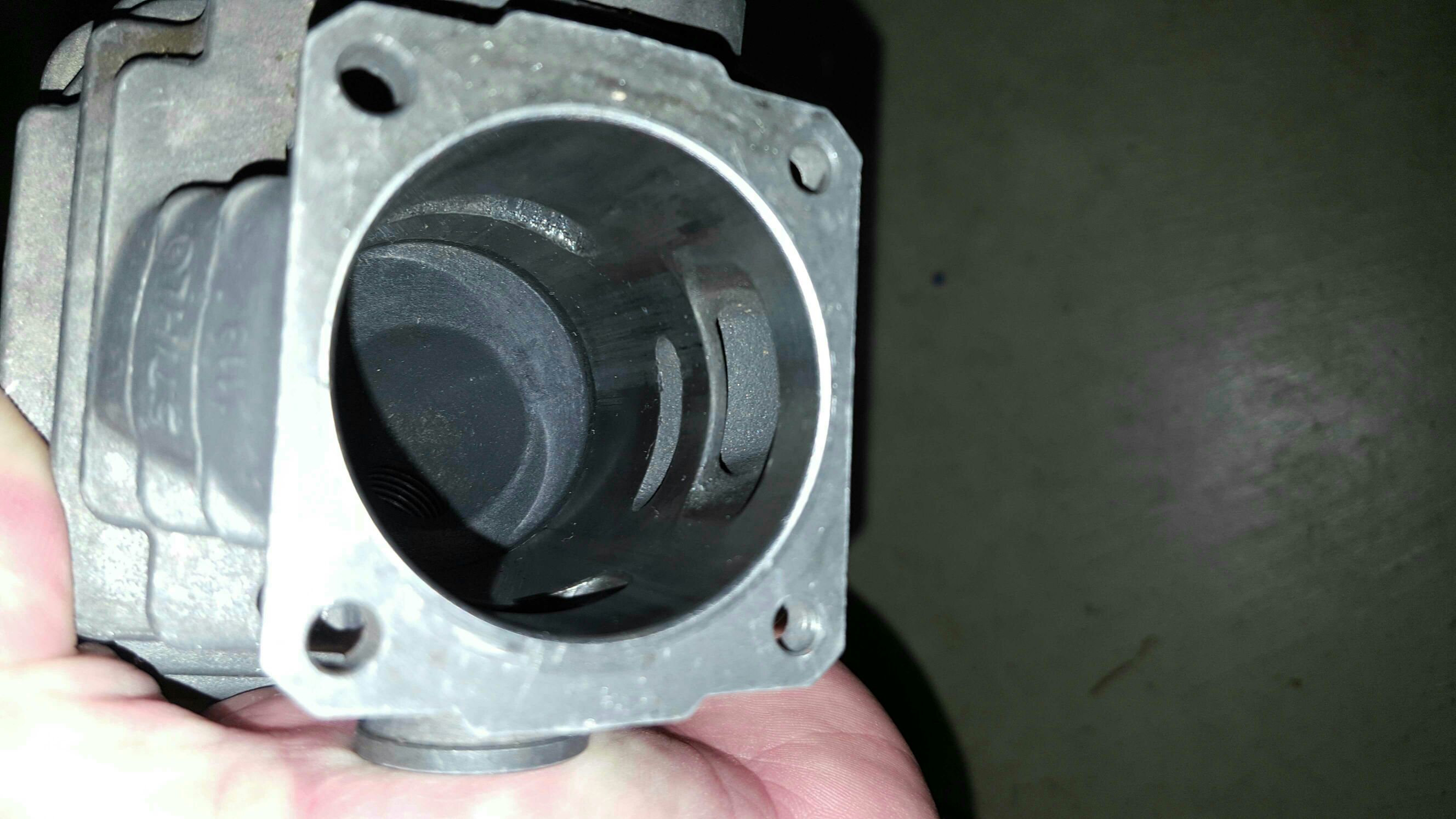

I was looking at that cylinder pic and marked a couple of spots that caught my (double visioned) eyes.

Did you smooth out or rework the chamfer/radius at the red marked areas?

That looks like something banged into the port edges (the piston ring?) and likely pushed up some metal that would be a problem now.

The other place ( marked yellow), has a streak coming from another place that I would double check the port edges.

Did you smooth out or rework the chamfer/radius at the red marked areas?

That looks like something banged into the port edges (the piston ring?) and likely pushed up some metal that would be a problem now.

The other place ( marked yellow), has a streak coming from another place that I would double check the port edges.

Attachments

Those case halves really came out nice.

briantutt

Addicted to ArboristSite

Those case halves really came out nice.

Yeah, I have a little ultrasonic cleaner. Really works great.

briantutt

Addicted to ArboristSite

Took advantage of the super cold weather. Chilled the case half with crank outside, mating half heated in oven set at 350 for 10 minutes or so. Slipped right together. If I torque the case bolts it is very stiff, loosen the bolts it spins freely. I have tried a few good raps with a brass mallet but still too stiff. Any ideas? The mallet trick worked on several other saws I did. Odd thing is that with the heat & cold I easily slipped the mating case half all the way on to the gasket.

I think this is one of the reasons why they say to dry assemble or test fit the pieces. I believe you will have to machine the sides of the rod at the bearing slightly to narrow the piece -- filing or maybe even sandpaper might even do it. I would hate to see those fine chips or dust get lodged in the crankcase.

Check to see if it's the needle bearing or the rod itself that is causing the stiff rub.

Check to see if it's the needle bearing or the rod itself that is causing the stiff rub.

Jason Pitcher

Born to tinker, forced to work.

Hey I am rebuilding one of these to.

captain dangers

partner 1633B (skil) chainsaw

could the new main bearings be slightly thicker in diameter,? thus reducing tolerance and interfering with the fit ? did you measure the new bearings against the old?just a thought CDTook advantage of the super cold weather. Chilled the case half with crank outside, mating half heated in oven set at 350 for 10 minutes or so. Slipped right together. If I torque the case bolts it is very stiff, loosen the bolts it spins freely. I have tried a few good raps with a brass mallet but still too stiff. Any ideas? The mallet trick worked on several other saws I did. Odd thing is that with the heat & cold I easily slipped the mating case half all the way on to the gasket.View attachment 700664

View attachment 700649

briantutt

Addicted to ArboristSite

could the new main bearings be slightly thicker in diameter,? thus reducing tolerance and interfering with the fit ? did you measure the new bearings against the old?just a thought CD

I did not measure the old vs. new but I am convinced it is sideways pressure because the bearings are fully seated cases fully mated without using the bolts, just cold and heat. All I do is back off the torque and everything spins freely. If it was a bearing OD thing it would still be tight because everything is mated.

captain dangers

partner 1633B (skil) chainsaw

hiI did not measure the old vs. new but I am convinced it is sideways pressure because the bearings are fully seated cases fully mated without using the bolts, just cold and heat. All I do is back off the torque and everything spins freely. If it was a bearing OD thing it would still be tight because everything is mated.

when I referred to diameter , I meant the actual thickness as it sounds like your new bearings may be ever so slightly thicker, which could nip the crank. did you measure the thickness of old and new? I'm sure the inner/outer fit is fine. CD

Similar threads

- Replies

- 69

- Views

- 4K