You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tutorial: make your own raker depth gauge supported by software tool

- Thread starter hannes69

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Which file guide?

7/32” for 3/8” chain.

Which model or brand of file guide?

Philbert

One of the design features of this type of chain was to simplify sharpening, by allowing both the top plate and side plate cutting edges to be sharpened at the same time with a round file.

https://patents.google.com/patent/US2622636

"Another object of the invention is to provide a chain link embodying a cutting element that functions both as a side cutter and as a bottom router and whereby the arrangement is such that the operation of filing and sharpening is simplified;"

There are many different designs of file guides, which fix one or more variable for consistent results on each cutter:

- top plate cutting angle (typically 25° - 35°);

- top plate cutting bevel (typically around 60°);

- 'down angle' (typically 0° or 10°);

- cutter length;

etc.

If you want to file outside of the expected ranges (e.g. if you like a deeper 'hook' angle) you may not be able to sharpen both edges at the same time with some types of guides. Other guides, such as the Granberg styles, let you set all 4 of those variables (above). https://www.arboristsite.com/community/threads/granberg-file-n-joint-revisited.193630/

As long as you have a way that works for you, that is what is important.

Philbert

https://patents.google.com/patent/US2622636

"Another object of the invention is to provide a chain link embodying a cutting element that functions both as a side cutter and as a bottom router and whereby the arrangement is such that the operation of filing and sharpening is simplified;"

There are many different designs of file guides, which fix one or more variable for consistent results on each cutter:

- top plate cutting angle (typically 25° - 35°);

- top plate cutting bevel (typically around 60°);

- 'down angle' (typically 0° or 10°);

- cutter length;

etc.

If you want to file outside of the expected ranges (e.g. if you like a deeper 'hook' angle) you may not be able to sharpen both edges at the same time with some types of guides. Other guides, such as the Granberg styles, let you set all 4 of those variables (above). https://www.arboristsite.com/community/threads/granberg-file-n-joint-revisited.193630/

As long as you have a way that works for you, that is what is important.

Philbert

Just under 1/16 on chisel or 1.5+mm.Get the gullet. Still need the outside cutting edge of the tooth, tho I'm sure someone somewhere would argue otherwise. LOL

Nevertheless! You could Polish the rest for aerodynamics and less coefficient of friction for chip roll

Semi or round/chipper chain is a different story.

OK...I'm ready now!

What wrong here?

Stihl RM 3/8 cutter height from top of tie strap to leading edge of cutter

(13/64 or 5.2mm file) = .0246" (Hannes)

"Pogo's " RM 46, .404 (732 or 5.5mm file)

.039" = 1mm

5.75 mm

6×40 = .240 - 6 = 234 - 10 = 224

So the .404 uses a file 1/64 bigger yet its .022"...or about 1/50 lower cutter??

Pogo's seems correct to me.

I don't even think a new 3/8 RM will swallow a 7/32 file. (5.5mm)

What wrong here?

Stihl RM 3/8 cutter height from top of tie strap to leading edge of cutter

(13/64 or 5.2mm file) = .0246" (Hannes)

"Pogo's " RM 46, .404 (732 or 5.5mm file)

.039" = 1mm

5.75 mm

6×40 = .240 - 6 = 234 - 10 = 224

So the .404 uses a file 1/64 bigger yet its .022"...or about 1/50 lower cutter??

Pogo's seems correct to me.

I don't even think a new 3/8 RM will swallow a 7/32 file. (5.5mm)

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$59.99 ($0.40 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$39.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$56.99 ($0.38 / Foot)

$59.99 ($0.40 / Foot)

Double Braid Arborist Rope Orange(1/2 in x 150 ft) Arborist Rigging Polyester Rope - 48 Strand Rope Swing for Tree Bull Rope for Outdoor, Climbing, Swing, Sailing

Cosirulnta Shop

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$56.99 ($0.38 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

$14.99

$17.99

Fiskars Pole Saw Blade Replacement for Fiskars Pruning Saws and Tree Pruners, 15" Blade with Woodzig Chainsaw-Style Tooth Design

AMZ South Supply

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

hannes69

ArboristSite Operative

Maybe nothing´s wrong here, only a misunderstandingOK...I'm ready now!

What wrong here?

Here a pic of Stihl 3/8 RM chain, positioned in rectangular manner for measurements on the computer monitor.

The two red lines show the misunderstanding

What I call 'cutter height' in the context of my software and the raker depth gauge tools is the distance between the leading edge of a new cutter and the landing point of the gauge tool type 1 (here in the middle of the follwing tie strap). I tried to find short names for the software, and so they are maybe partially misleading, couldn´t find a better short name...

You see: the bottom of the cutter´s gullet has a much higher position relative to the 'bar' than the middle of the tie strap.

So the red line on the right measures indeed 246 mil.

The red line on the left measures 205 mil. That means 5.2mm and that means using a 13/64" file

Of course I don´t know, what measurement Pogo took exactly. And I don´t know the geometry of a .404 chain, I assume there are not only differences in the pitch itself but also in other dimensions.

BTW look at the pic above, you see the tie strap has a ramp style, so there are differences in measurements depending on the position on the tie strap. For my example of the gauge tool type 1, the pivot point of the tool lands on the middle of the tie strap, so I took the measurement from there.

Thnx..Maybe nothing´s wrong here, only a misunderstanding

Àà

Here a pic of Stihl 3/8 RM chain, positioned in rectangular manner for measurements on the computer monitor.

View attachment 654685

The two red lines show the misunderstanding

What I call 'cutter height' in the context of my software and the raker depth gauge tools is the distance between the leading edge of a new cutter and the landing point of the gauge tool type 1 (here in the middle of the follwing tie strap). I tried to find short names for the software, and so they are maybe partially misleading, couldn´t find a better short name...

You see: the bottom of the cutter´s gullet has a much higher position relative to the 'bar' than the middle of the tie strap.

So the red line on the right measures indeed 246 mil.

The red line on the left measures 205 mil. That means 5.2mm and that means using a 13/64" file

Of course I don´t know, what measurement Pogo took exactly. And I don´t know the geometry of a .404 chain, I assume there are not only differences in the pitch itself but also in other dimensions.

BTW look at the pic above, you see the tie strap has a ramp style, so there are differences in measurements depending on the position on the tie strap. For my example of the gauge tool type 1, the pivot point of the tool lands on the middle of the tie strap, so I took the measurement from there.

Right, I was aware of that as you already straightened me out on that. I was looking at the illustration on page one that looks like the same height and got 'side tracked' as you would think I should know what a chain looks like by now

Just lost my train of though as I started using file size for prespective once I converted his measurement back into thou then 'back to mm'.

Well that's a good thing then. Much better it be my mistake than yours

I believe the raker to cutter distance was 9?? or was it 11?? thou more than the same run on the 3/8.

Now you wondered earlier in a post

about the only difference from the Husqvarna gauges softwood settings being the .404 was a little thinner than the 3/8.

I remember the thinner .404 gauge converted to about .003" more depth. I though then this possibly was the reason but then I saw It was a different style of gauge it brought doubt that they all are made that thin? would have to check it with the same style of Husky gauges that look like the .325 and 3/8 on this thread to know for certain?

So it looks like there is a .019" cutter height difference measured from the bottom of the gullet to top of cutter........ 13/64 vs 7/32 (14/64) difference of 1/64 file size.

Rounf 19 thou up to 20 thou gives you a 1/50 fraction.

*Edit bottom

I would believe the height difference is 1/64 and runs on the same 11.8°

They would loose raker height as the tooth is set back 9 thou from the raker but a gain as the higher cutter will reach higher in attach mode.

hannes69

ArboristSite Operative

Here I show the numbers for the .404 Stihl chain, ASSUMING a cutter´s angle of 11.8° (I don´t have the measurement).Now you wondered earlier in a post

about the only difference from the Husqvarna gauges softwood settings being the .404 was a little thinner than the 3/8.

First, putting the Husky .404 gauge with soft setting onto it:

The soft setting seems to be suitable as hard setup, it´s too weak as soft setup I think.

Now the numbers for optimized type 1 and type 2 settings (hard setup / trying to maintain the initial cutting angle).

Type 1:

More or less the same behaviour comparfed to the 3/8 chain.

Type 2:

For the chain´s first half of life perfect behaviour, the second half is alittle bit worse compared to the 3/8 chain but very acceptable in my opinion.

So with the given assumption of the same cutter´s angle, the optimized raker depth tools seem to work for the .404 chain as well.

Would of course be nice to get the missing number, some measurements of a .325 chain and maybe a 3/8 chain other than Stihl

This is not right. I don't need 'those guys' to argue with. (Considered displaced!)

*Edit bottom

I would believe the height difference is 1/64 and runs on the same 11.8°

They would loose raker height as the tooth is set back 9 thou from the raker but a gain as the higher cutter will reach higher in attach mode.

Not a true statement.

As long as the raker depth is proportionate to the cutter height then the only things that will change the attack 'height' (depth) is the radius of the raker and the radius of the leading edge. BTW, the radius of the cutter (leading edge) may also vary with different chains? (Pivot to leading edge)

* You need to go to a saw shop and they will give you an assortment of short pieces from different NEW chains that are laying around. Very handy to have around when using a bar rail puller also.

hannes69

ArboristSite Operative

I try to make now some conclusions regarding the topic 'optimum cutting angle'.

When using Carlton´s pictures and argumentations, it seems that optimum cutting angle = constant cutting angle. Like I assumed from the beginning of this thread

It´s only a matter of deciding the value of the cutting angle according to different parameters.

When you like to maintain the performance of a chain using an initial raker depth setting, you simply have to maintain the according cutting angle.

Using Carlton´s pics and assuming an according behaviour of the cutting chain, the corresponding calculations reveal this (attention, the table´s columns now show different entities than formerly):

'Attack depth' means the penetration depth of the cutter in the cutter´s attack position.

The chip size is the sum of the attack depth and the extra depth generated during the lifting off of the cutter.

In this case a 'cutting angle' of 6.3° is maintained through the cutter´s life.

We see: At ~270 mil cutter wearing the attack depth becomes negative. At 320 mil wearing the leading edge of the cutter is already positioned behind the hinge point before getting to the attack position, so no useful numbers for this position.

The chipsize is constant (54.1 - 54.7 mil).

Now the same table maintaining a cutting angle of 8.0°:

Same behaviour, the attack depth becomes more negative towards the end.

Remembering the softwood chip size Westboastfaller has delivered (according to Carlton) ? 63 mil? We´re in the same ballpark here.

Last table now, showing the chip size when putting the optimized gauge type 2 onto the Stihl 3/8 chain:

At this point I see consistency between Carlton´s argumentation and my numbers.

Many discussions here seem to make circles around the actual value of teh cutting angle that has to be taken, which influences we have, which parameters.

The theory regarding the 'optimal cutting angle' won´t answer this. In my opinion it only gives the direction to go for a constant value in order to maintain a given performance level. This level itself is a result of the personal setup with all possible parameters. My personal setup asks for a cutting angle of 7° when using Stihl RM 3/8 chain with my 034 S saw and the wood type I cut.

I cut an elder tree these days in the garden, diameter 14 inches with my saw using a 16 inch bar. When bucking it, the saw had optimal performance when only using the saw´s weight; when pushing additionally, the saw started to bog and when pushing a little bit more the chain stopped to spin. The cut was always smooth. Exactly that is the behaviour I like, big chips only by the pressure out of the saw´s own weight.

I´m satisfied with an angle of 7.0° as an 'all purpose' setting, like the Stihl RM chain. Maybe for certain purposes a RS chain would be better, or a different cutting angle, but I personally like the all purpose approach. You can´t go VERY wrong with a RM chain and a cutting angle of 7° in my opinion, regardless what´s your plan

When using Carlton´s pictures and argumentations, it seems that optimum cutting angle = constant cutting angle. Like I assumed from the beginning of this thread

It´s only a matter of deciding the value of the cutting angle according to different parameters.

When you like to maintain the performance of a chain using an initial raker depth setting, you simply have to maintain the according cutting angle.

Using Carlton´s pics and assuming an according behaviour of the cutting chain, the corresponding calculations reveal this (attention, the table´s columns now show different entities than formerly):

'Attack depth' means the penetration depth of the cutter in the cutter´s attack position.

The chip size is the sum of the attack depth and the extra depth generated during the lifting off of the cutter.

In this case a 'cutting angle' of 6.3° is maintained through the cutter´s life.

We see: At ~270 mil cutter wearing the attack depth becomes negative. At 320 mil wearing the leading edge of the cutter is already positioned behind the hinge point before getting to the attack position, so no useful numbers for this position.

The chipsize is constant (54.1 - 54.7 mil).

Now the same table maintaining a cutting angle of 8.0°:

Same behaviour, the attack depth becomes more negative towards the end.

Remembering the softwood chip size Westboastfaller has delivered (according to Carlton) ? 63 mil? We´re in the same ballpark here.

Last table now, showing the chip size when putting the optimized gauge type 2 onto the Stihl 3/8 chain:

At this point I see consistency between Carlton´s argumentation and my numbers.

Many discussions here seem to make circles around the actual value of teh cutting angle that has to be taken, which influences we have, which parameters.

The theory regarding the 'optimal cutting angle' won´t answer this. In my opinion it only gives the direction to go for a constant value in order to maintain a given performance level. This level itself is a result of the personal setup with all possible parameters. My personal setup asks for a cutting angle of 7° when using Stihl RM 3/8 chain with my 034 S saw and the wood type I cut.

I cut an elder tree these days in the garden, diameter 14 inches with my saw using a 16 inch bar. When bucking it, the saw had optimal performance when only using the saw´s weight; when pushing additionally, the saw started to bog and when pushing a little bit more the chain stopped to spin. The cut was always smooth. Exactly that is the behaviour I like, big chips only by the pressure out of the saw´s own weight.

I´m satisfied with an angle of 7.0° as an 'all purpose' setting, like the Stihl RM chain. Maybe for certain purposes a RS chain would be better, or a different cutting angle, but I personally like the all purpose approach. You can´t go VERY wrong with a RM chain and a cutting angle of 7° in my opinion, regardless what´s your plan

I never converted the "Type 1" until now .566" and .047"

This is surprising.

Much thicker and steeper than the Husqvarna gauges.

3/8, hard setting Stihl - 14.38mm

Material thickness 1.19 mm

-------------------------------------------------

".325 'Soft' Position -- 14.80mm

.325 'Hard' Position -- 19.00mm

Material Thickness -- .84mm

3/8 'Soft' Position -- 19.00mm

3/8 'Hard' Position -- 23.30mm

Material Thickness -- .84mm

.404 'Soft' Position -- 19.00mm

.404 'Hard' Position -- 22.00mm

Material Thickness -- .75mm"

(19mm base to slot.)

The .325 hard & 3/8 soft also both (19mm) which came in at 6.3 ( .025" ) depth cutting angle with the Stihl 3/8 RM. (Pg 9)

The thickness difference of the .404 gauge is 3.5 thou which makes up the difference. (28.5 thou

The raker is further from the cutter slightly which accounts for a bit of a loss

I would assume the 3/8 Oregon chain will have a slightly closer raker and/or a slight bit more clearance from cutter to strap. It will come in a proper .030" with the thicker husky gauge. The .404 gauge would definitely be a good 'go to gauge' nearing the end.

This is surprising.

Much thicker and steeper than the Husqvarna gauges.

3/8, hard setting Stihl - 14.38mm

Material thickness 1.19 mm

-------------------------------------------------

".325 'Soft' Position -- 14.80mm

.325 'Hard' Position -- 19.00mm

Material Thickness -- .84mm

3/8 'Soft' Position -- 19.00mm

3/8 'Hard' Position -- 23.30mm

Material Thickness -- .84mm

.404 'Soft' Position -- 19.00mm

.404 'Hard' Position -- 22.00mm

Material Thickness -- .75mm"

You initially got 28.5 thou with the husky .404 gauge on the Stihl .404.Here I show the numbers for the .404 Stihl chain, ASSUMING a cutter´s angle of 11.8° (I don´t have the measurement).

First, putting the Husky .404 gauge with soft setting onto it:

View attachment 655263

The soft setting seems to be suitable as hard setup, it´s too weak as soft setup I think.

Now the numbers for optimized type 1 and type 2 settings (hard setup / trying to maintain the initial cutting angle).

Type 1:

View attachment 655264

More or less the same behaviour comparfed to the 3/8 chain.

Type 2:

View attachment 655265

For the chain´s first half of life perfect behaviour, the second half is alittle bit worse compared to the 3/8 chain but very acceptable in my opinion.

So with the given assumption of the same cutter´s angle, the optimized raker depth tools seem to work for the .404 chain as well.

Would of course be nice to get the missing number, some measurements of a .325 chain and maybe a 3/8 chain other than Stihl

(19mm base to slot.)

The .325 hard & 3/8 soft also both (19mm) which came in at 6.3 ( .025" ) depth cutting angle with the Stihl 3/8 RM. (Pg 9)

The thickness difference of the .404 gauge is 3.5 thou which makes up the difference. (28.5 thou

The raker is further from the cutter slightly which accounts for a bit of a loss

I would assume the 3/8 Oregon chain will have a slightly closer raker and/or a slight bit more clearance from cutter to strap. It will come in a proper .030" with the thicker husky gauge. The .404 gauge would definitely be a good 'go to gauge' nearing the end.

So you are running them both to get the best possible numbers? What would stop the Stihl gauge of not being able to at least match the numbers if not exceed them as its not limited to the rivet.Now the numbers for optimized type 1 and type 2 settings (hard setup / trying to maintain the initial cutting angle).

I would have liked to see what the Stihl gauge would do on the taller cutter compared to the 3/8 Stihl.

Hard setting? Maybe in the middle.

Misunderstanding again?

Trx250r180

Saw polisher

I just eyeball the cutter and let the wood tell me if it needs more off the rakes. Sorry i'm late Jamie.

hannes69

ArboristSite Operative

Not so surprising I thinkI never converted the "Type 1" until now .566" and .047"

This is surprising.

Much thicker and steeper than the Husqvarna gauges.

You obviously can trade in 'pivot length' for 'material thickness' and vice versa.

Thicker material -> you have to go steeper for the same results.

Thinner material -> you have to go less steep for the same results.

So if you like to switch from .047" material to .033" material (the 0.84mm of teh Husky gauge) you simply have to change the pivot length from .566" to .750" in order to get similar numbers.

Results:

.047" and .566":

0.033" and .750":

The numbers are not identical but more or less the same.

A material thickness of 0.047" leads to a tool that is mechanically more robust than using 0.033" material. I see no (obvious) reason why Husqvarna used such a thin material (maybe it´s a standard material from their suppliers, who knows).

Maybe misunderstanding. The numbers for optimized type 1 and type 2 settings mean:So you are running them both to get the best possible numbers? What would stop the Stihl gauge of not being able to at least match the numbers if not exceed them as its not limited to the rivet.

I would have liked to see what the Stihl gauge would do on the taller cutter compared to the 3/8 Stihl.

Hard setting? Maybe in the middle.

Misunderstanding again?

I want to show numbers independantly for the two different types of depth gauge tools (to still compare them). Optimized means: I want to use ONE setting and ONE tool. So no dual gauge. The initial angle of 6.8° should be maintained as well as possible and the depth gauge tool should start with this value when put onto a new chain. Of course you could allow some overshoot, then the result would be better for the end of life point of the chain and worse for the first half.

I assume with mentioning 'Stihl gauge' you mean 'type 1 gauge' ? I still don´t know what you mean with 'the taller cutter compared to 3/8 Stihl' ? I always use my Stihl 3/8 RM chain example, only at the beginning of this thread I showed some numbers for 3/8 Carlton low profile chain and later on theoretical numbers for a 'virtual' .404 chain. In all other cases I use the Stihl 3/8 RM chain.

I started reading this thread, but unfortunately it got fairly nasty fairly quickly, which was a bit unfare on the OP I think. He was just offering something, you're free to move on if you don't like it.

Anyway, I think the software is a good tool for determining the angle you want or need. I don't want to derail the OP's intent, but if making up the gauge is not practical for you, you can simply just draw it up on paper and check.

Just work out the angle you want from the OP's software, and then take the tangent of it. If you're not up on maths, there are tables for this stuff, or you can just google it (literally just type "tan 6 degrees" into the search bar and it will tell you, then invert this number ot get your 1 in ___ value to use for the ratio. Will work for any angle). Then just string out your chain along some useful reference (I used the tops of two teeth on the same side), and then see where the raker sits in relation to the line.

Maybe not practical for every day use, but for when you're doing a full refurb of your chain it might be useful of your normal method of setting the depths (i.e. 3 files per tank of fuel, or whatever you do).

Anyway, I think the software is a good tool for determining the angle you want or need. I don't want to derail the OP's intent, but if making up the gauge is not practical for you, you can simply just draw it up on paper and check.

Just work out the angle you want from the OP's software, and then take the tangent of it. If you're not up on maths, there are tables for this stuff, or you can just google it (literally just type "tan 6 degrees" into the search bar and it will tell you, then invert this number ot get your 1 in ___ value to use for the ratio. Will work for any angle). Then just string out your chain along some useful reference (I used the tops of two teeth on the same side), and then see where the raker sits in relation to the line.

Maybe not practical for every day use, but for when you're doing a full refurb of your chain it might be useful of your normal method of setting the depths (i.e. 3 files per tank of fuel, or whatever you do).

Attachments

Not quite sure what you are trying to establish...., a variable for the formula or a parameter for making a gauge

Would that not simply represent the same approach (or obtain the same result) as using a center drop fixed depth tool? Using an additional tooth to determine the relationship of a raker to a different tooth seems to defeat the purpose of the progressive concept, especially if the two teeth are different lengths (heights). Granted, the variance would probably be negligible, but after all, this thread has been unusually focused on splitting hairs..., Swedish ones at that! LOL

Then just string out your chain along some useful reference (I used the tops of two teeth on the same side), and then see where the raker sits in relation to the line.

Would that not simply represent the same approach (or obtain the same result) as using a center drop fixed depth tool? Using an additional tooth to determine the relationship of a raker to a different tooth seems to defeat the purpose of the progressive concept, especially if the two teeth are different lengths (heights). Granted, the variance would probably be negligible, but after all, this thread has been unusually focused on splitting hairs..., Swedish ones at that! LOL

- Joined

- Dec 6, 2014

- Messages

- 21,333

- Reaction score

- 25,448

Blonde hairs?

I don't think it would. It's just an analogue version of using the DAF that was shown in the other threads. If it was constant depth, the lower blue line wouldn't be angled, it would be parallel (i.e. like the lower red line in the image attached). Unless I'm misunderstanding you?

The tops of the teeth are just a useful reference point, and I agree that all your teeth would need to be very close to the same height and length for this to be a useful reference. I know mine are because I recently spent some time ensuring this. You could just as easily use the bottoms or any other part that would notionally be parallel with the bar.

The tops of the teeth are just a useful reference point, and I agree that all your teeth would need to be very close to the same height and length for this to be a useful reference. I know mine are because I recently spent some time ensuring this. You could just as easily use the bottoms or any other part that would notionally be parallel with the bar.

Attachments

hannes69

ArboristSite Operative

Yes, there were many people in this thread not liking my approach and they obviously didn´t move onHe was just offering something, you're free to move on if you don't like it.

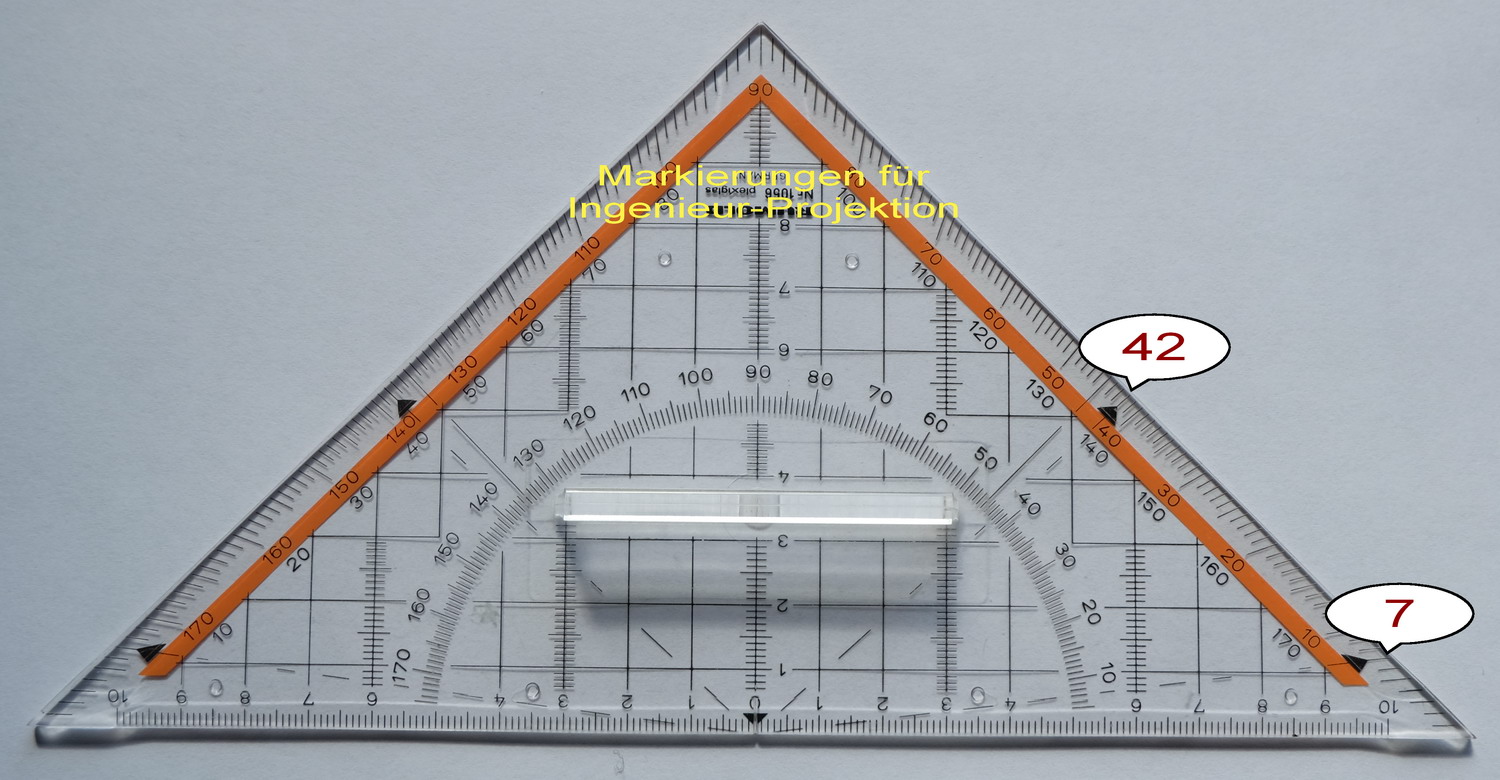

You can do it like that, but normally you don´t have to fiddle around with tangens or math when you want to know the angle. At least in Germany every pupil sitting the first time in a math class is obliged to own this tool called 'geometry triangle':Just work out the angle you want from the OP's software, and then take the tangent of it.

So after making your two lines you can simply measure the angle without doing calculations

Yes. I used a ruler as a 'bar' aligned with a piece of paper or my desk, then I made my measurements of the chain (sitting onto the ruler) itself.You could just as easily use the bottoms or any other part that would notionally be parallel with the bar.

Similar threads

- Replies

- 8

- Views

- 2K