GusGus2020

ArboristSite Operative

Nice 298 there!Couple of good runners old school torque

Nice 298 there!Couple of good runners old school torque

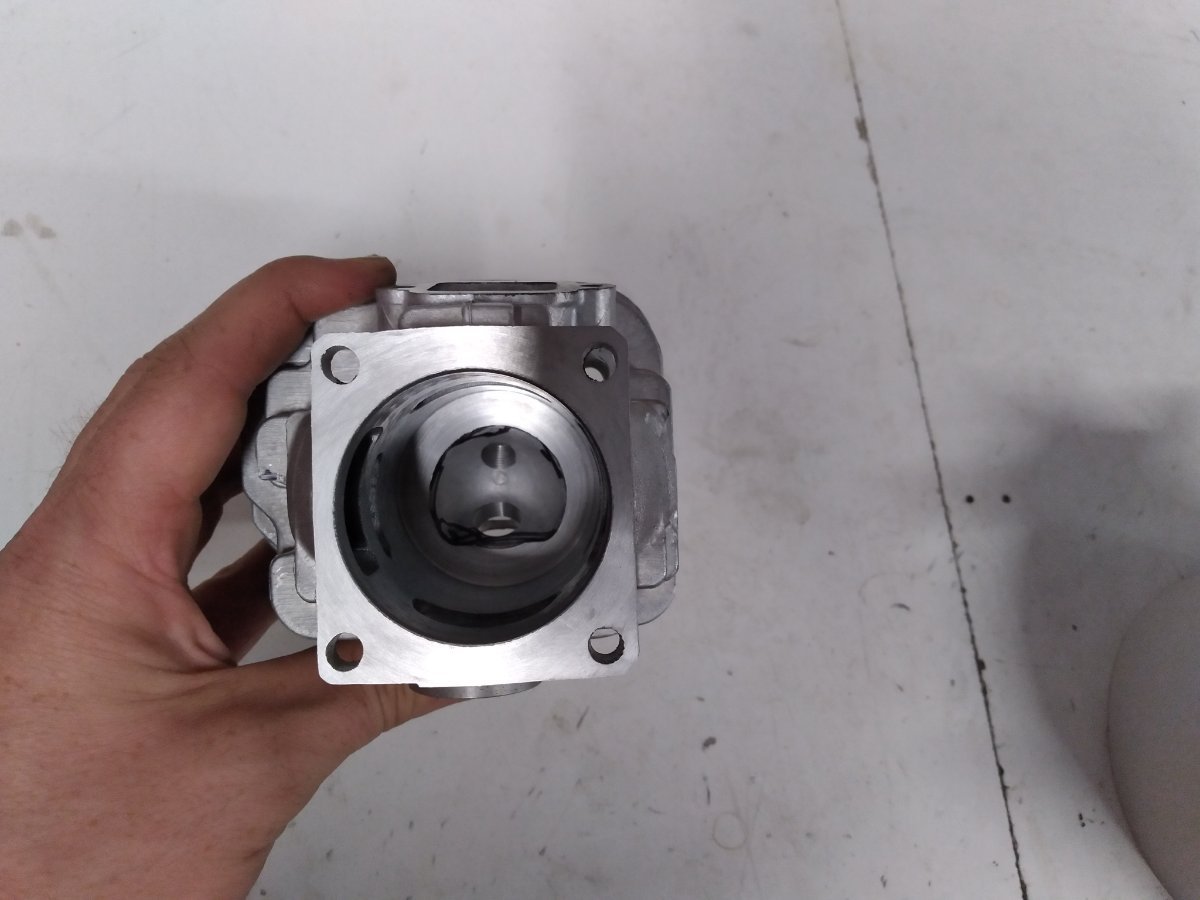

Yea just put new rings and crank seals it has very strong compression old school don’t make like that anymore.Nice 298 there!

If you need to source a starter pawl let me know and I'll hit up a buddy, he should have one or two he'd get rid of.2100 that I’ve been slowly putting back together. Got it on a trade for some other saw repair work. Had a chunk missing from the tank handle, plastics were really faded, was caked with dirt…looking much better now - I’ll see if I regret taking the base gasket out. Squish is still at .037. - It’s missing one of the starter pawls, so I still need to address that before running it too much. A few other odds and ends to take care of, but I’m looking forward to having this in the stable.View attachment 1011552View attachment 1011554

2100 that I’ve been slowly putting back together. Got it on a trade for some other saw repair work. Had a chunk missing from the tank handle, plastics were really faded, was caked with dirt…looking much better now - I’ll see if I regret taking the base gasket out. Squish is still at .037. - It’s missing one of the starter pawls, so I still need to address that before running it too much. A few other odds and ends to take care of, but I’m looking forward to having this in the stable.View attachment 1011552View attachment 1011554

Gave it a little workout today

I'd say it'll work, a buddy runs a Maxflow foam element over a Stihl HD2 filter on his 066 and it works just fine. I'd still oil that prefilter, though. I've got about 1/2 a bottle of filter oil that can go with the pawl if you want some.Best of both worlds, or too much?View attachment 1012324

What sorta oil do you use? I get mine soaking wet, while yours still looks pretty dry.It’s been oiled - it’s part of a Uni I had on my 181 - I was getting more fines through than I liked, so I got these K&Ns that I thought might seal a bit better. With both the pre filter and cones oiled, hopefully it’ll stop most anything now…

Is that a small cardboard box you have there?