Stumpys Customs

Stumpbroke

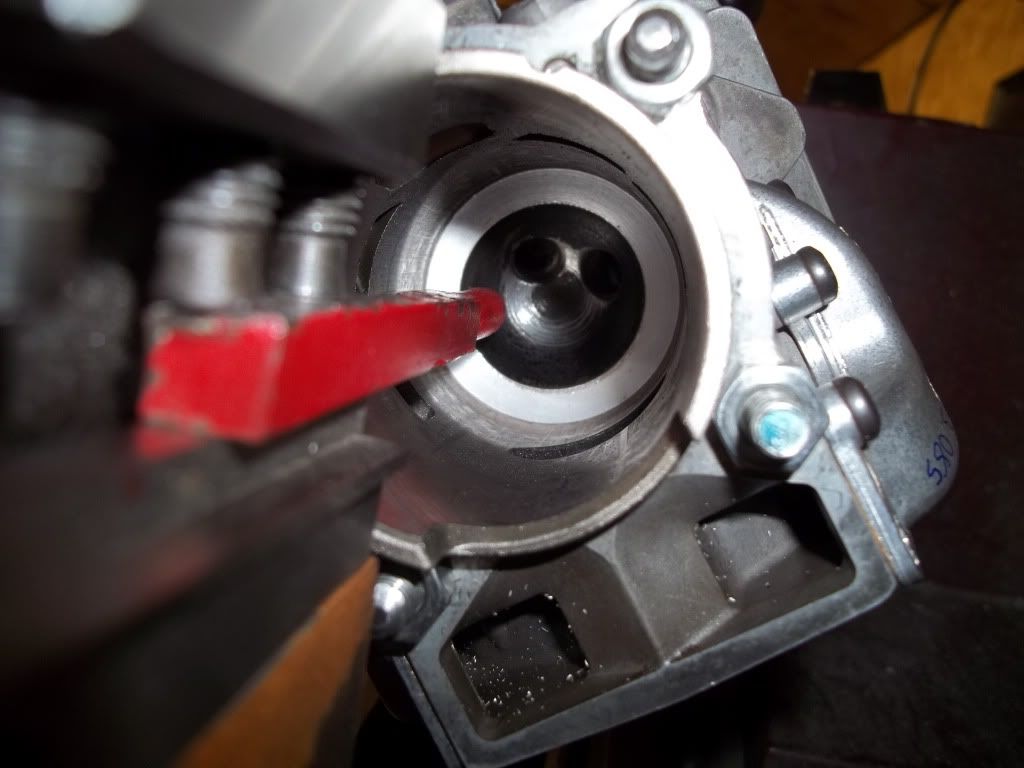

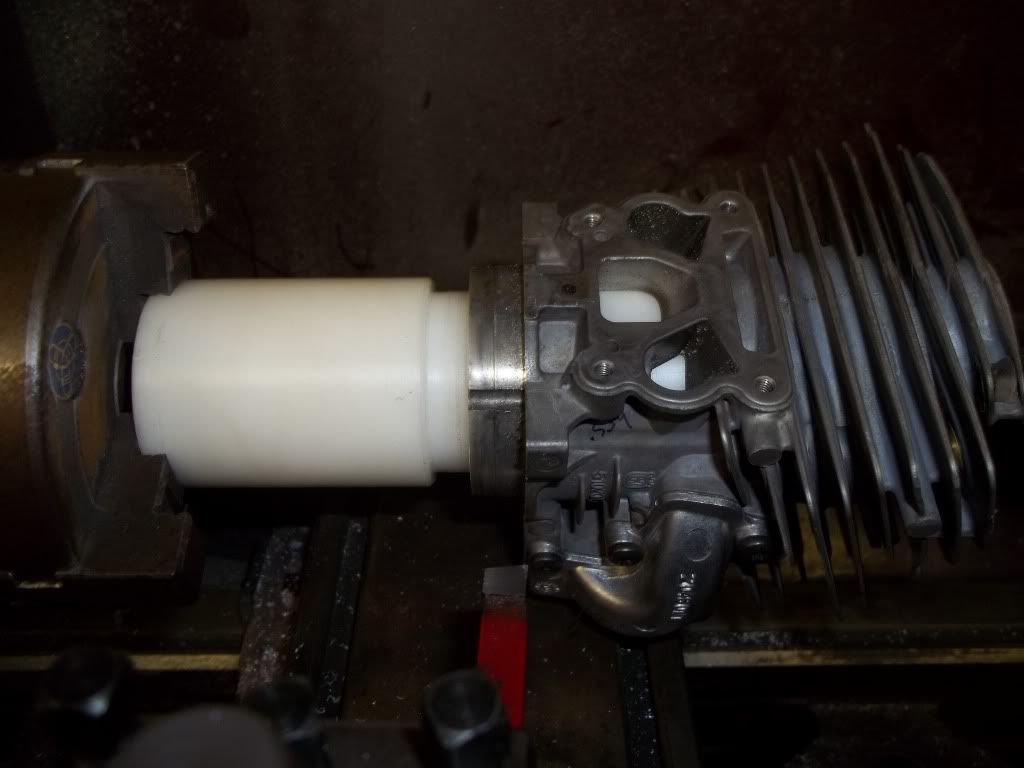

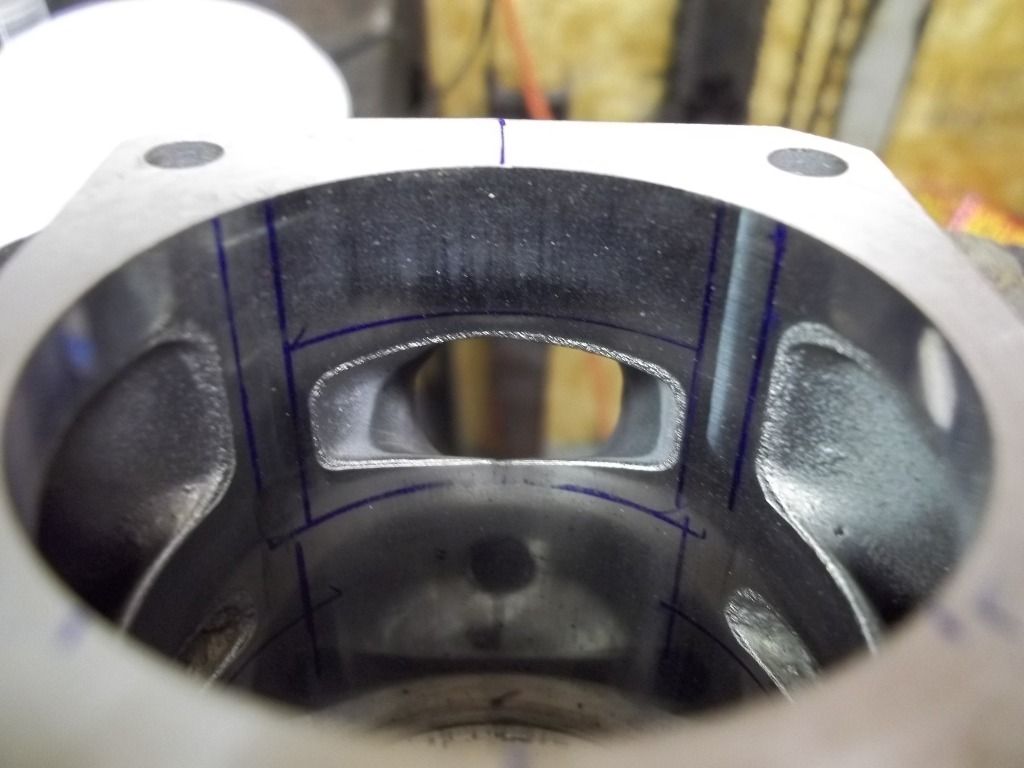

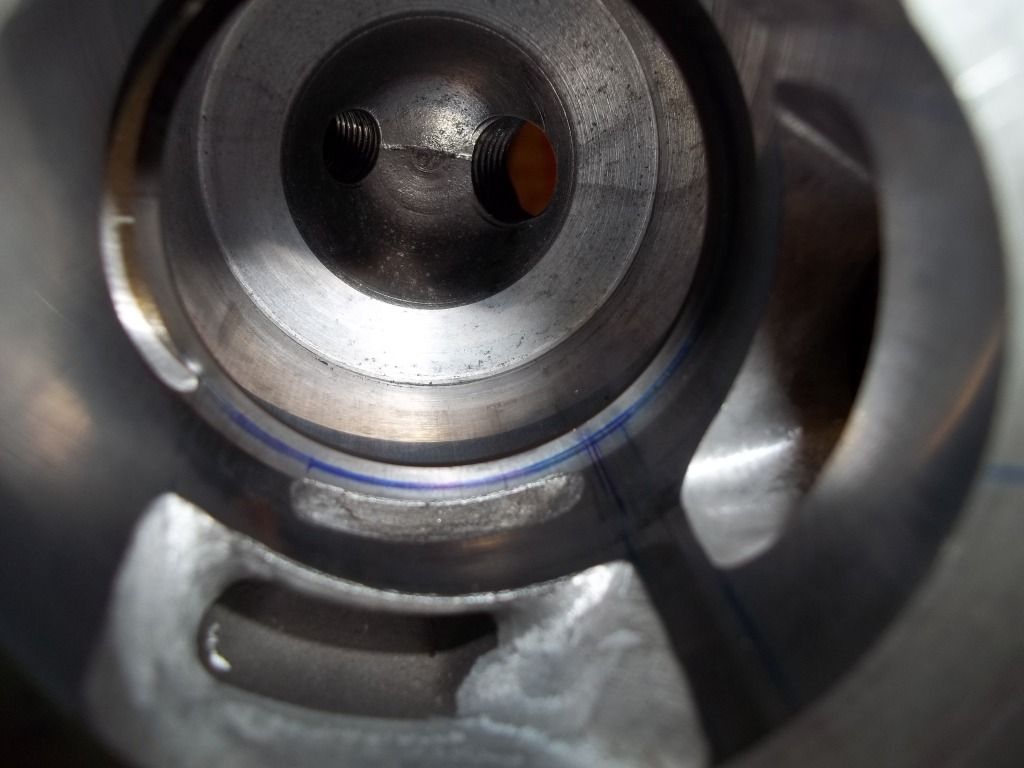

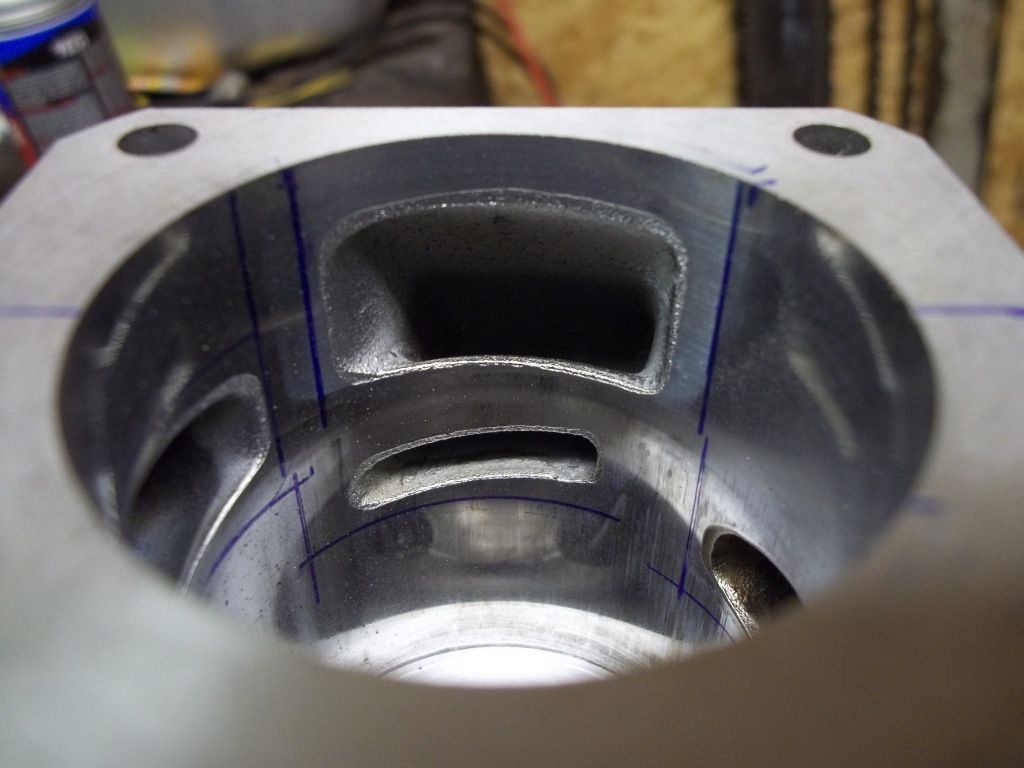

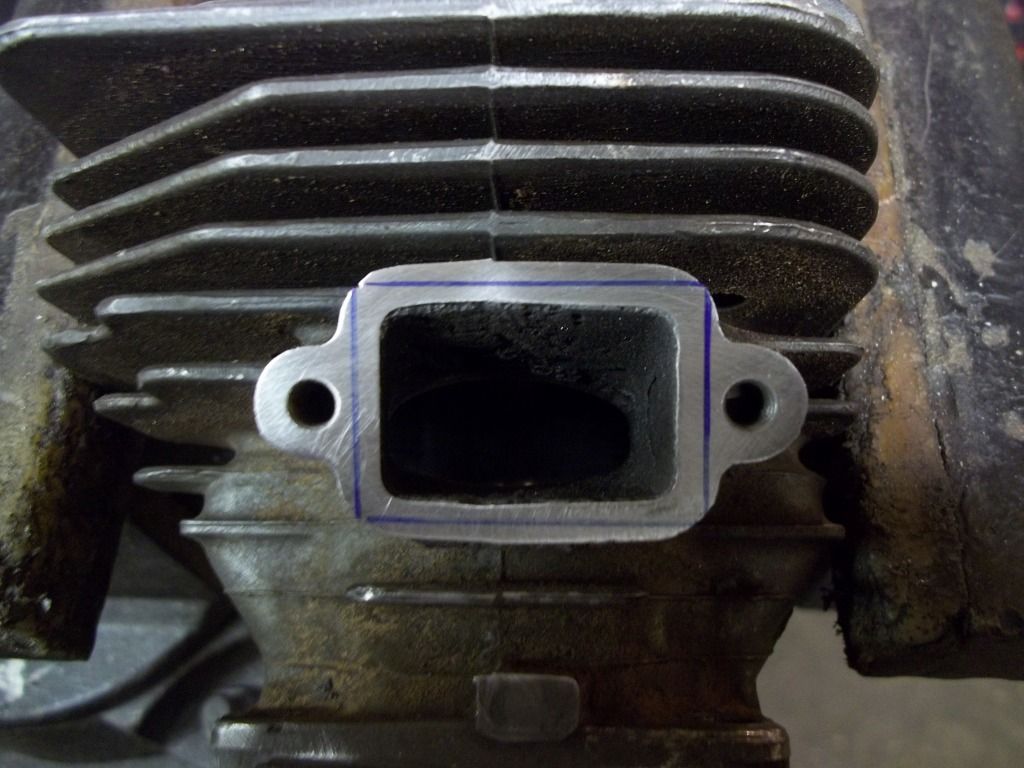

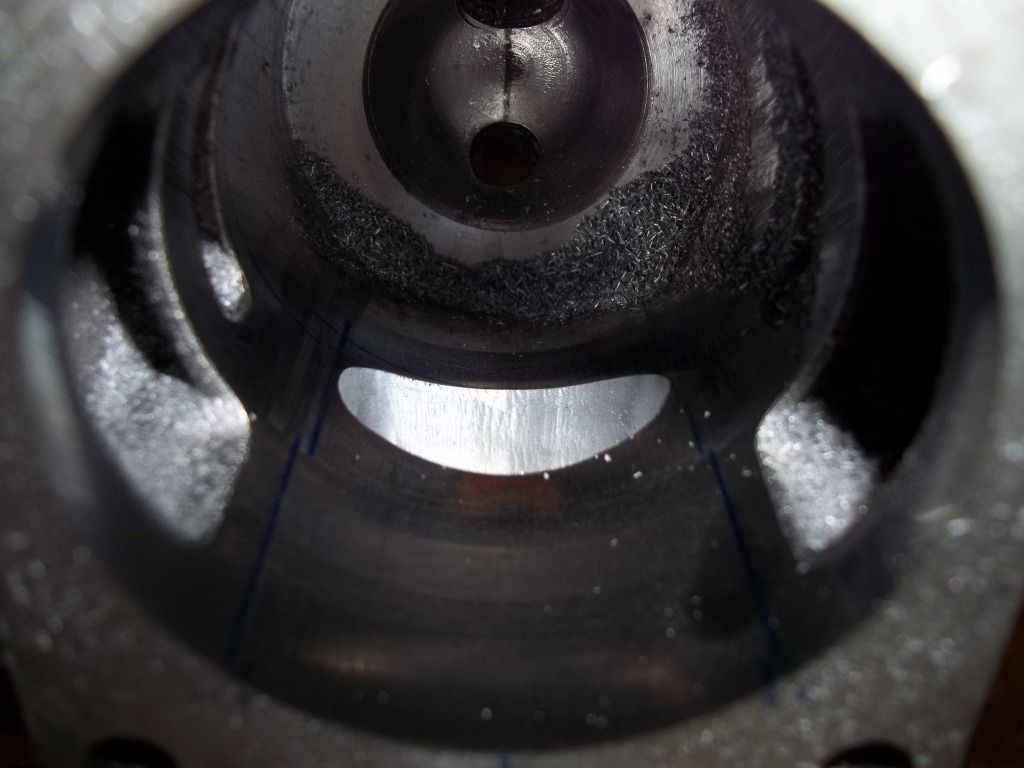

Thought a few of ya's might want a lil more in depth look at how I port a saw. I'll be using my current project a Stihl MS460 to illustrate. Feel free to ask ?'s. I'll do my best to answer. I do want to add this is not the only way to do it, just the way I do it.

Just a run of the mill well used MS460 with a couple of new parts to go with it.

Normal grit & grime from being used for it's intended purpose.

The first step is to get everything as clean as possible. I have a parts washer outside the shack that the saws take a bath in.

Just a run of the mill well used MS460 with a couple of new parts to go with it.

Normal grit & grime from being used for it's intended purpose.

The first step is to get everything as clean as possible. I have a parts washer outside the shack that the saws take a bath in.