Moparmyway

Its just a saw

- Joined

- Dec 2, 2012

- Messages

- 2,481

- Reaction score

- 3,401

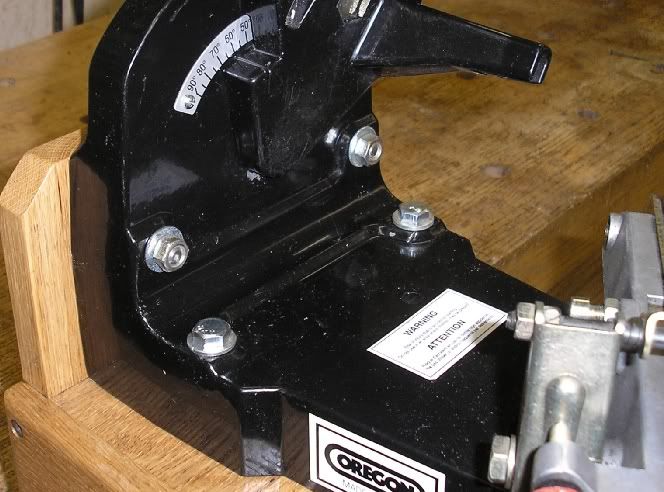

View attachment 339846 View attachment 339847

I made a plate for both switches and the wires are tucked away nicely .........

You need 2 switches. You can keep the origional to energize and de-energize the hot leg. Then use a DPDT switch to switch EITHOR the start winding or the run winding. On mine, the start winding was the red and blue leads from the motor-with the red to the capacitor. The black and green leads are from the run winding. The "start winding" is really the split part of the split pole motor, and not really a "start winding" as it never drops out, but shifts the phase to bring in an additional winding which aids in starting and helps the motor run stronger. Anyway ........ I kept the cap circuit wired in straight and I decided to switch the run winding, so I set the switch up to swap the run wires with the hot and neutral wires. Works like a champ !!Great ideas. Love to see some photos!

A few years back someone posted instructions for making the motor reversible - anybody got it?

Somebody suggested that if they increased the range of motion for the head tilt and vise, you could grind both Left and Right cutters the 'right way' without a reversing motor, and the guarding problems associated with that.

Philbert

I made a plate for both switches and the wires are tucked away nicely .........