Mastermind

Work Saw Specialist

I've got a video uploading......it will be an hour or so before it's done.

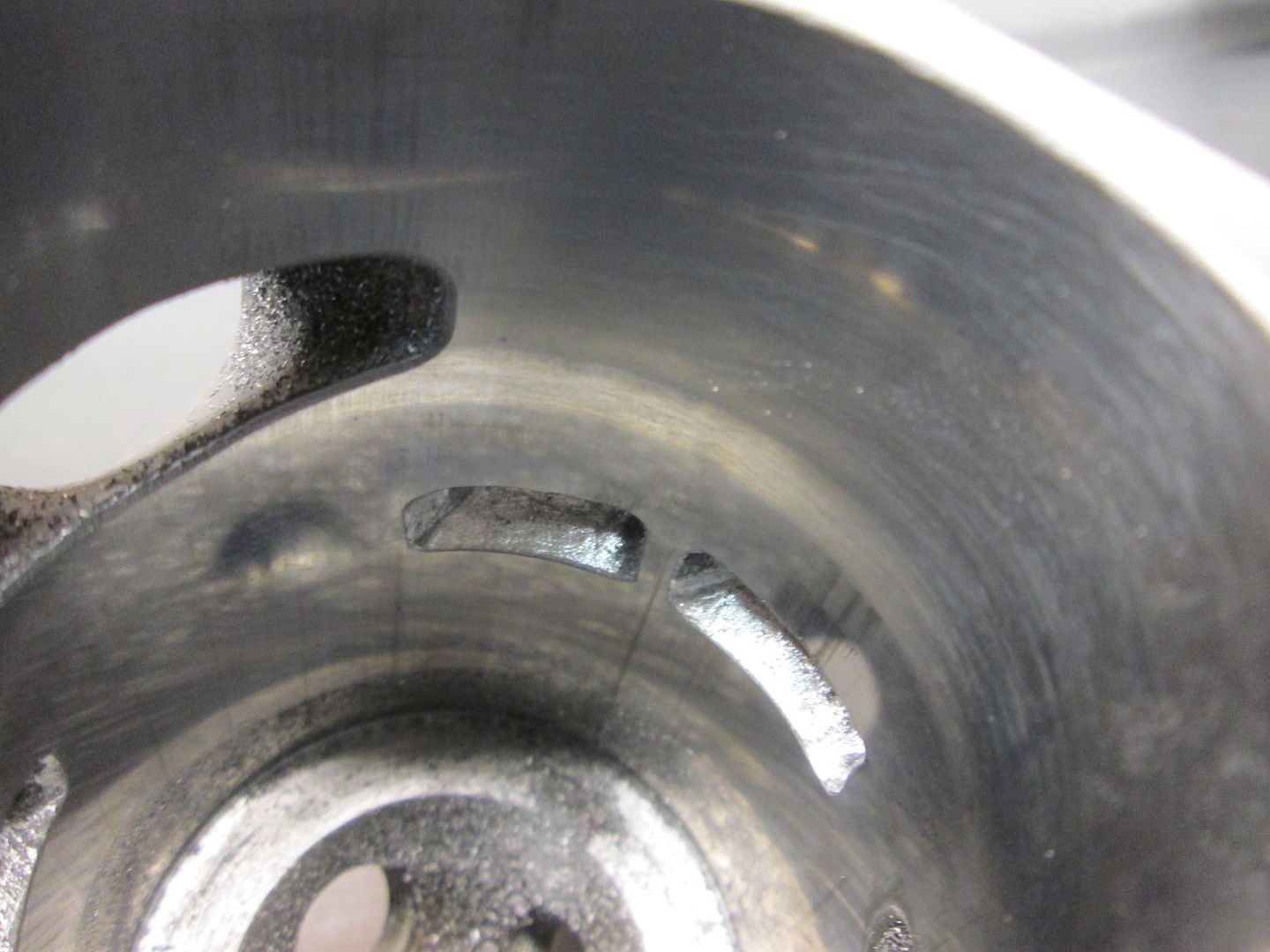

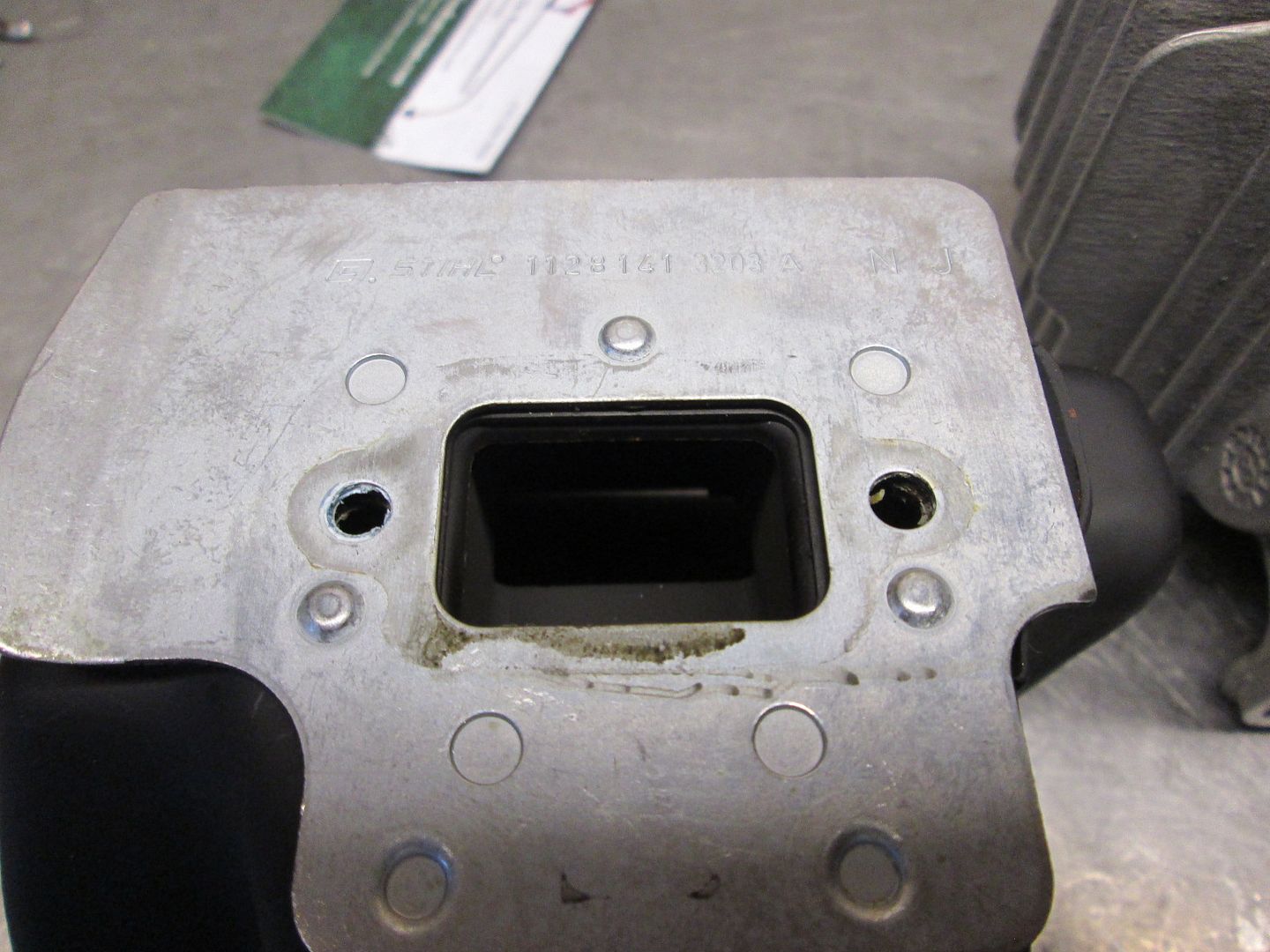

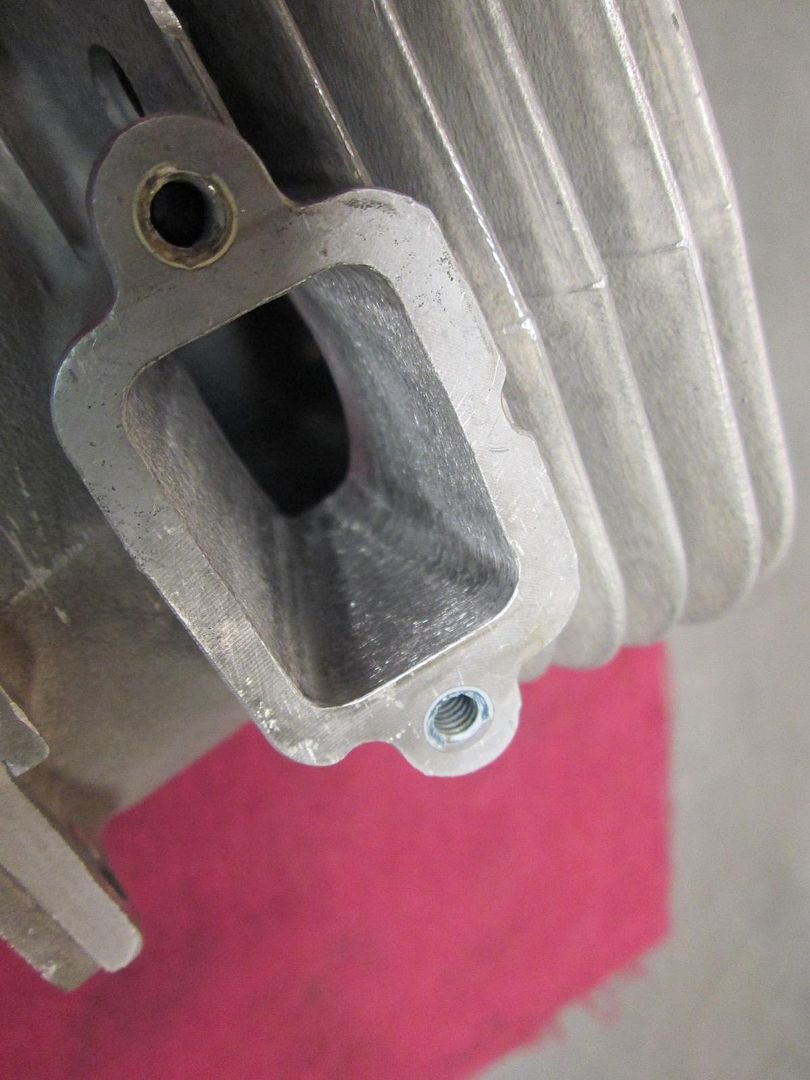

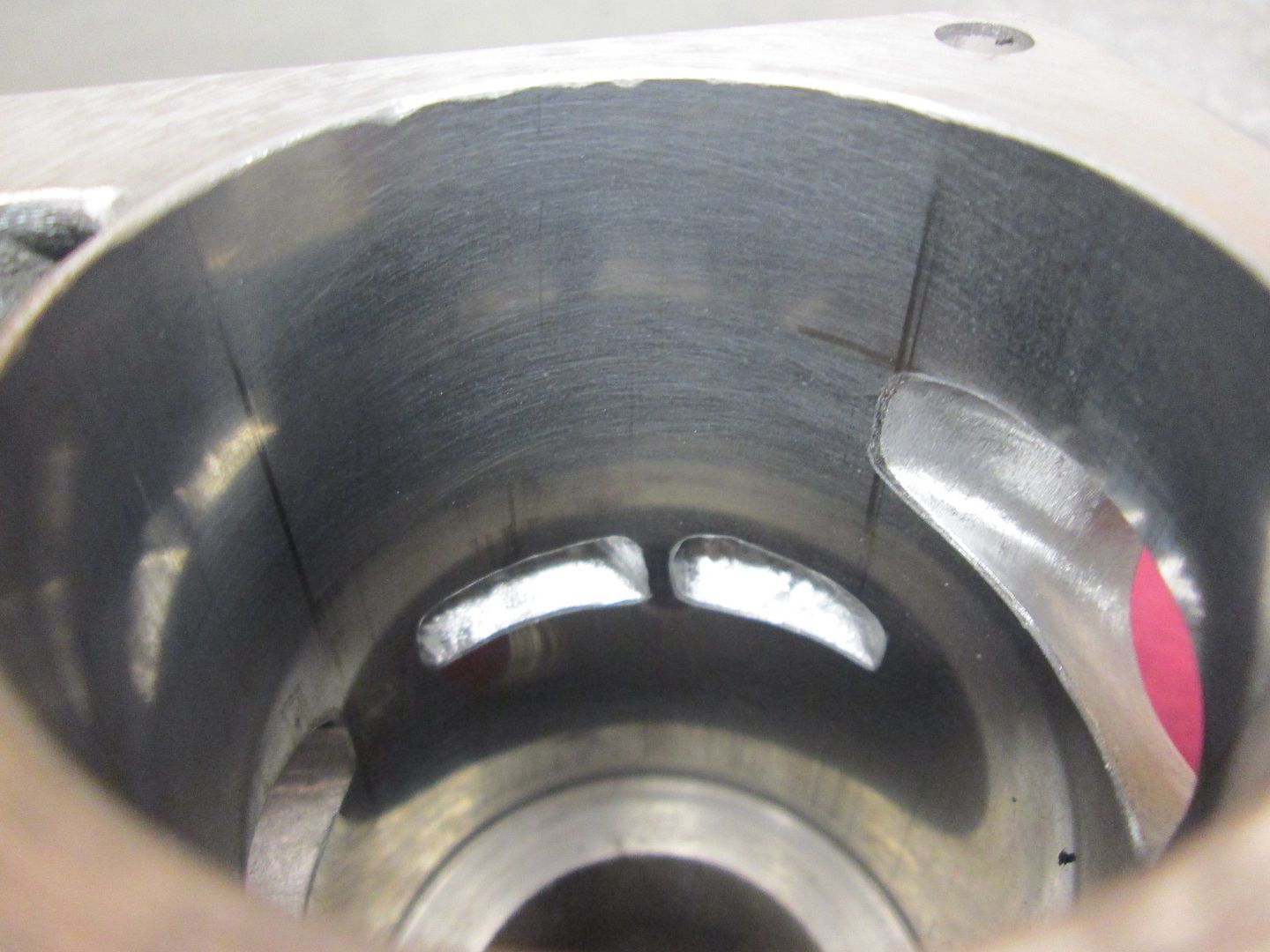

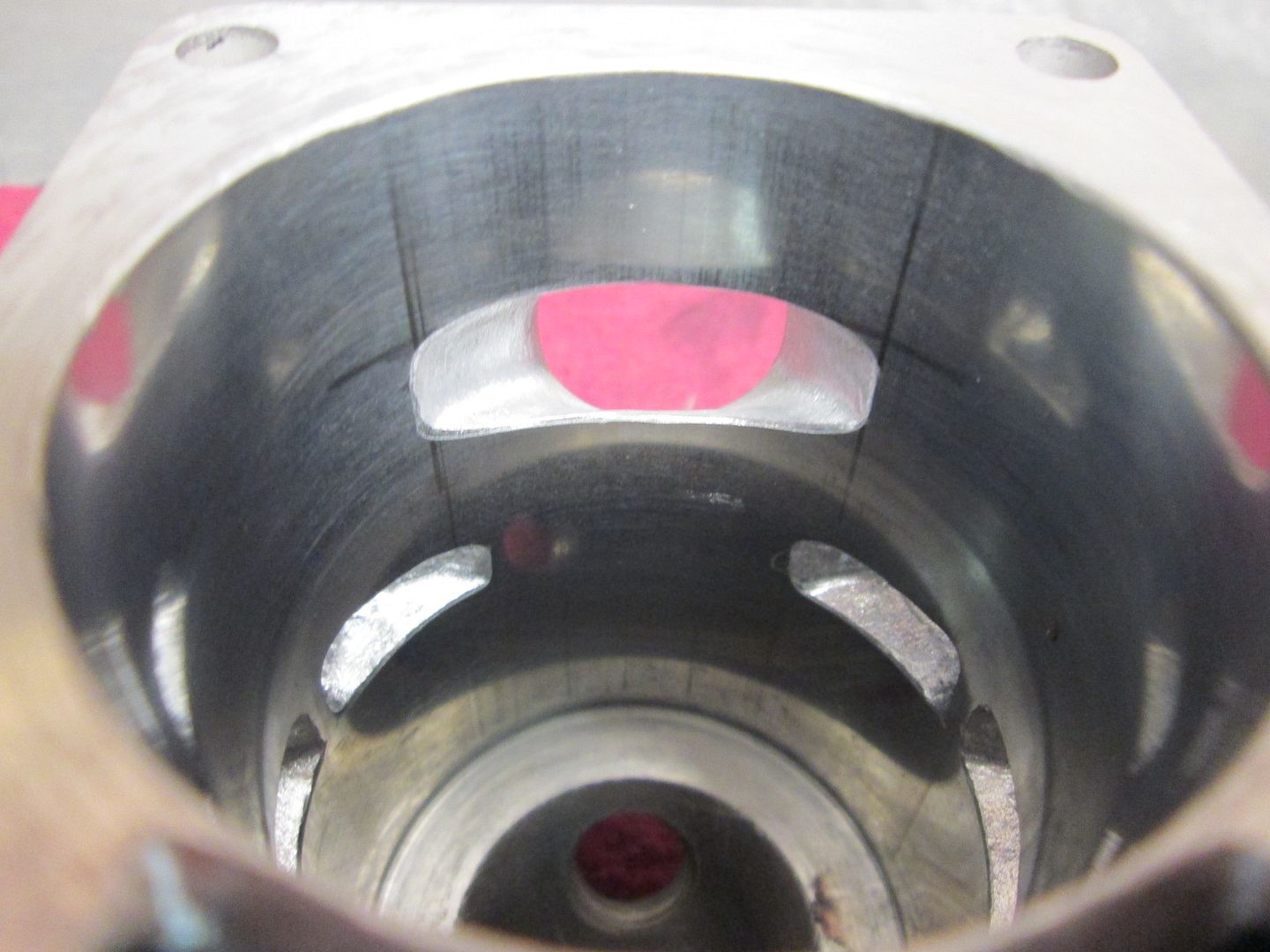

Its all good as long as youNow, I'm trying to decide how much I should share on my port work..........I've spent a lot of time learning how to get repeatable results on the port heights.

I'm of the belief that knowing how I do it, and actually doing it yourself is two different things, so I'm just gonna spill all the beans here.

Keep them coming as long as they aren't videos of you and Thomas1 in the sack, you can spoon him all you like while somebody kicks him, but please don't film it!028 more minutes and I'll post another funny talkin video.....

Enter your email address to join: