You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Craftsman 2.3

- Thread starter Opihi59

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I've got a 2.3 craftsman,(no a/v), and it's kind of a mustard yellow color.

Anybody ever see one? Canadian color scheme or something?

That depends, I have seen that color on 25 series saws but not a Micro based XXV.

That is a very fine looking saw and you got it for a great price. The only saws I ever remember my dad owning were little top handle Poulans, mostly because he got them free from a family member who owns a tree business. I am personally a Craftsman junky so I like it from both sides.

It seems that the Craftsman/Poulan saws are always "on sale" at ebay. I don't think you can find a better chainsaw in the $30 range. If it had been a Stihl, Husqvarna or Echo top handle you could add more than $100 more for it and these Poulans are just as good, easier to service.

That saw looks like my old Sear's 2.3, I changed out the bar long ago to a 16" with thumb tension adjuster for the chain. Someone borrowed my saw, brought it back in the case and said thanks. Two years later I got it out to service it, to start trimming with it and found out it had no compression. I pulled the saw down and found they had burnt up the jug and piston. So now the saw sits in its case till one day I find a free good junked out one. Still have the owner's manual put up. One day she will run. :frown:

Frank Boyer

Addicted to ArboristSite

I have a 70's Craftsman/poulan XXV 2.3 cu in and it is yellow. It has points, and no AV. I got it used from a tree guy for $25 in 1977 or so.

Opihi59

ArboristSite Operative

You need a service manual for that saw, so you need to send me a PM with a email address......

Searched more here at home, minus the firewall at work and found this thread you had posted up in last year. I'm linking it in for my own selfish purposes so I can find it later.

http://www.arboristsite.com/chainsaw/120981.htm

I read thru it and downloaded the 2 page PDF that you linked into that thread, but still if you have a more pages I have planny room in the AOL address I PM'd you. Looks pretty straightforward to me, so I'll dig in to it more, pull the clutch assy etc. Yesterday I pulled the pump assembly--the black plastic piece--I hooked a spare hose to it and could blow thru it, but not suck back thru it so my impression is that aspect of the system is okay. I will pull the check valve but will not use pressurized air on it. In the link above you noted that this part was available and listed a PN 530069142 I am finding thru my usual sources I get these things that they are NLA, so if you know a source let me know about it.

I'll wait on further instructions and admonitions.

$204.65

Oregon 295453/S Yukon+ Type A Class 1 (20 m/s) Chainsaw Protective Trousers, Black, 3X-Large

Express Shipping ⭐⭐⭐⭐⭐

$225.16

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express Shipping ⭐⭐⭐⭐⭐

$59.99 ($0.40 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

$56.99 ($0.38 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

Opihi59

ArboristSite Operative

That saw looks like my old Sear's 2.3, I changed out the bar long ago to a 16" with thumb tension adjuster for the chain. Someone borrowed my saw, brought it back in the case and said thanks. Two years later I got it out to service it, to start trimming with it and found out it had no compression. I pulled the saw down and found they had burnt up the jug and piston. So now the saw sits in its case till one day I find a free good junked out one. Still have the owner's manual put up. One day she will run. :frown:

She'll run sooner if you send her to me. I'll come up with the parts and add her to my pile. I can give you mailing addresses in Anderson SC and Henderson KY so you don't have to pay too much for shipping. It will be worth your while and save you time and angst if you just box it up and PM me for mailing addresses. I'm always ready to help. :msp_wink:

Sorry but my little girl will never leave me again, had her when she was born on the show room floor at Sears. :smile2:

Opihi59

ArboristSite Operative

Modifiedmark, I got your email and thank you. Will work on this and post up more info, and pollute the forum with more of my photos. I'll likely send you some more questions so I can look smart and post up all your knowledge in this thread.

So I decided to give some stuff for the night crew to look at and took the thing apart. The clutch assembly on the 2.3 has two holes in it, they wouldn't fit my Angle grinder tool span, so I dug out a pin spanner from my kit of bike tools. Looks like this, spun off the clutch no problems.

So now we're looking at this. The small black hole above the single bar mount stud is the oiler outlet hole. And the shiny hex head is the check valve.

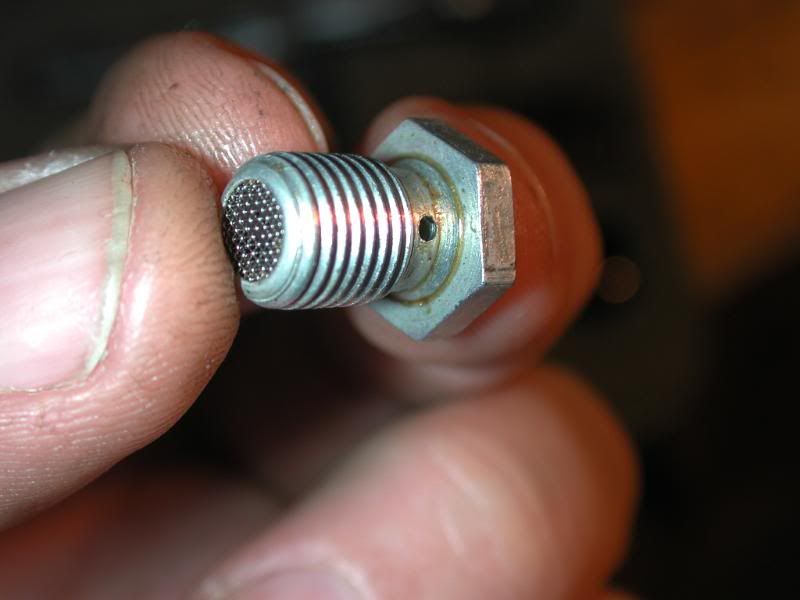

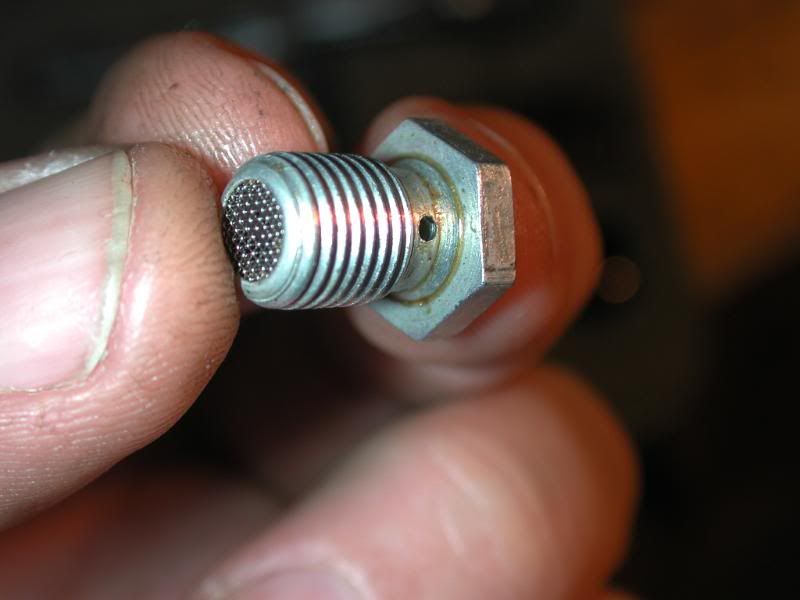

This is the check valve, removed.

If I put the threaded end in my mouth, I can both suck air and also blow air thru the thing. I don't believe that is how this is supposed to work. But Modifiedmark will have to help confirm. No bad jokes about the blowing/sucking thing. We're trying to fix saws here, and we're all grownups and professionals, right?

Here is the hole into the crankcase where the check valve has been removed.

And now on to a new post so I don't hit the photo limiter.

So I decided to give some stuff for the night crew to look at and took the thing apart. The clutch assembly on the 2.3 has two holes in it, they wouldn't fit my Angle grinder tool span, so I dug out a pin spanner from my kit of bike tools. Looks like this, spun off the clutch no problems.

So now we're looking at this. The small black hole above the single bar mount stud is the oiler outlet hole. And the shiny hex head is the check valve.

This is the check valve, removed.

If I put the threaded end in my mouth, I can both suck air and also blow air thru the thing. I don't believe that is how this is supposed to work. But Modifiedmark will have to help confirm. No bad jokes about the blowing/sucking thing. We're trying to fix saws here, and we're all grownups and professionals, right?

Here is the hole into the crankcase where the check valve has been removed.

And now on to a new post so I don't hit the photo limiter.

Opihi59

ArboristSite Operative

More on the oiler mechanism

Now here is the cover over the oiler mech that sits in the oil tank. Remove the two screws....

There is a filter, oiler mech and the oil hose. The other end of the hose is the oil outlet just above the single bar stud.

So I can SUCK thru the hose connected to the oiler mechanism, but I cannot BLOW thru it. I believe I got my sucking and blowing confused in a previous thread, this is the correction. Can suck thru it, but cannot blow thru this hose.

This is the oiler hose, I just pulled it out and will put in a new hose, another bonus shot of the Hex head check valve as well. Interested if someone tells me whether or not my Hex check valve is toast.

All the wispy little hairs stuck to the stuff is compliments from Katie the Scottish Fold who donates hair equivalent to her body mass daily to everything I own, and barfs in my tool box as well. Meow.

Now here is the cover over the oiler mech that sits in the oil tank. Remove the two screws....

There is a filter, oiler mech and the oil hose. The other end of the hose is the oil outlet just above the single bar stud.

So I can SUCK thru the hose connected to the oiler mechanism, but I cannot BLOW thru it. I believe I got my sucking and blowing confused in a previous thread, this is the correction. Can suck thru it, but cannot blow thru this hose.

This is the oiler hose, I just pulled it out and will put in a new hose, another bonus shot of the Hex head check valve as well. Interested if someone tells me whether or not my Hex check valve is toast.

All the wispy little hairs stuck to the stuff is compliments from Katie the Scottish Fold who donates hair equivalent to her body mass daily to everything I own, and barfs in my tool box as well. Meow.

Opihi59

ArboristSite Operative

Parts

Anybody got a plug and a jug for sidwell's saw laying around? That's just too nice of a saw, with too good of a history to just let languish.

Sorry but my little girl will never leave me again, had her when she was born on the show room floor at Sears. :smile2:

Anybody got a plug and a jug for sidwell's saw laying around? That's just too nice of a saw, with too good of a history to just let languish.

Opihi59

ArboristSite Operative

Updating

I read thru the Service manual, looked over the saw and the mechanism involved, and feel that my Check valve isn't working. It should be a one-way device which allows pressurization of the oil tank from the crankcase, but should not allow pressure to escape back into the crankcase. My read on the Service manual and interpretation of how this should work tells me I should only be able to blow thru the check valve--the hex head one--from the threaded end, but should not be able to suck back thru the check valve. Otherwise, why have a check valve if it isn't designed to "check" something? I have figured I need a check valve so will be looking for a source. Seems they have just run out of them on the world market though. I may be fabricating up some sorta bodge job or looking for a used one from my usual source...............AS..............

I read thru the Service manual, looked over the saw and the mechanism involved, and feel that my Check valve isn't working. It should be a one-way device which allows pressurization of the oil tank from the crankcase, but should not allow pressure to escape back into the crankcase. My read on the Service manual and interpretation of how this should work tells me I should only be able to blow thru the check valve--the hex head one--from the threaded end, but should not be able to suck back thru the check valve. Otherwise, why have a check valve if it isn't designed to "check" something? I have figured I need a check valve so will be looking for a source. Seems they have just run out of them on the world market though. I may be fabricating up some sorta bodge job or looking for a used one from my usual source...............AS..............

Have you tried to flush it out with carb cleaner and compressed air, maybe its just stuck for sitting and not being used. It may have a spring loaded check ball in it and is stuck. Can hurt to try, not much to lose at this point.

Chris J.

Addicted to ArboristSite

Is my ignorance showing, or is that oiler set-up a lot more complicated than it needs to be?

Since when :msp_sneaky:?

...We're trying to fix saws here, and we're all grownups and professionals, right?...

Since when :msp_sneaky:?

Well its really a simple system that works of crank-case inpulse pressure, no gears or diaphram to wear out. Just have to losen oil tank cap when your'e done for the day so it stops pushing oil out.

Last edited by a moderator:

I learned the hard way on how the oiler worked, dumped oil all in my case, had oily gloves and files,,, that was a mess.

I read thru the Service manual, looked over the saw and the mechanism involved, and feel that my Check valve isn't working. It should be a one-way device which allows pressurization of the oil tank from the crankcase, but should not allow pressure to escape back into the crankcase. My read on the Service manual and interpretation of how this should work tells me I should only be able to blow thru the check valve--the hex head one--from the threaded end, but should not be able to suck back thru the check valve. Otherwise, why have a check valve if it isn't designed to "check" something? I have figured I need a check valve so will be looking for a source. Seems they have just run out of them on the world market though. I may be fabricating up some sorta bodge job or looking for a used one from my usual source...............AS..............

If you can blow and suck through the checkvalve, then it is bad and you need it replaced.

Is my ignorance showing, or is that oiler set-up a lot more complicated than it needs to be?

It must be as it is the simplest setup you could probably ever have.

As to your ignorance, I'll leave that one alone. (for now)

Opihi59

ArboristSite Operative

Carb cleaner

I'll give it a try with the carb cleaner. I'm not real sure what's inside there, some sort of rubber butterfly valve, spring and a ball bearing? At any rate, will give it a trial with spraying it out, and/or soaking. May not get to it tonite, I'm stuck at work and may not make it home.

I'll give it a try with the carb cleaner. I'm not real sure what's inside there, some sort of rubber butterfly valve, spring and a ball bearing? At any rate, will give it a trial with spraying it out, and/or soaking. May not get to it tonite, I'm stuck at work and may not make it home.

Well did you get it to work, dying to know?..:msp_confused:

Similar threads

- Replies

- 43

- Views

- 2K

- Replies

- 1

- Views

- 621