Opihi59

ArboristSite Operative

I replaced the oil lines on the Poulan version of one of those a couple of weeks ago. I scratched my head trying to figure out how it works. Must be the vibration of the saw or something. Maybe if Mark gets in the mood to type he can explain it.

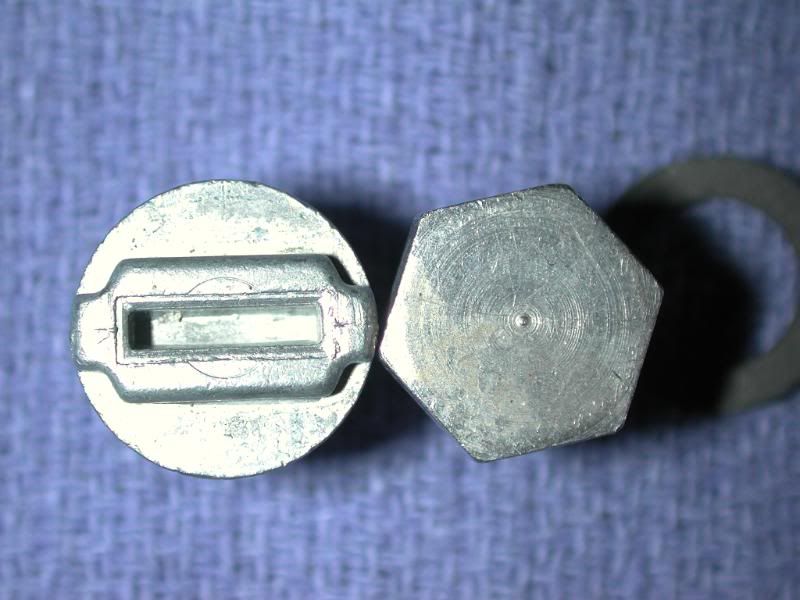

The pressure from the crankcase is fed thru a one way valve (the check valve) into the oil tank. In the oil tank there is a one way valve which then feeds oil out thru the oiler line to the oiler hole, and Bob's your Uncle. Pretty straight forward. Look at my pictures and read the narrative and it will make sense.