The cyl screws on my HL Farmertec kit are silver, right bolt in right place?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FarmerTec Huztl MS660 Updated Build Kit - Build Thread

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The cyl screws on my HL Farmertec kit are silver, right bolt in right place?

You probably used muffler bolts on your cylinder. Silver M6x20 are lower muffler bolts, black M6x25 are cylinder bolts.

MG porting

ArboristSite Guru

That would be bad.

I took my 660 out for a tune-up. It ran for about 2 minutes while I fumbled around looking for my tach and then it abruptly cut off. It did not load up and cut off, it just cut off so I knew something was wrong. I suspected a fuel issue. I emptied my fuel tank. Took my pressure guns hose and blew my line out to remove the fuel and then did a pressure test. I had a leak. My leak was at the elbow going into the tank. My local store had one, I will pick it up tomorrow.

I secretly hoped it was not anything bad. How that occurred who knows. I did put a piece of r3 between the elbow and carb. Must have cracked it.

I secretly hoped it was not anything bad. How that occurred who knows. I did put a piece of r3 between the elbow and carb. Must have cracked it.

MG porting

ArboristSite Guru

For some reason mine will idle and run normal full throttle but and it's a big but if I sit it down and let it idle for a bit then tap the throttle it will die I'm so done with this carb I'm going to break down and get a Tillotson hs-320a.I took my 660 out for a tune-up. It ran for about 2 minutes while I fumbled around looking for my tach and then it abruptly cut off. It did not load up and cut off, it just cut off so I knew something was wrong. I suspected a fuel issue. I emptied my fuel tank. Took my pressure guns hose and blew my line out to remove the fuel and then did a pressure test. I had a leak. My leak was at the elbow going into the tank. My local store had one, I will pick it up tomorrow.

I secretly hoped it was not anything bad. How that occurred who knows. I did put a piece of r3 between the elbow and carb. Must have cracked it.

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

MG porting

ArboristSite Guru

I would get a walbro but they want a ton of money for them.I am using a wj-76 walbro. Works good

I paid like 55$I would get a walbro but they want a ton of money for them.

MG porting

ArboristSite Guru

Wow!!! Was that new or used??I paid like 55$

Oh, Gees, I screwed up. Not.You probably used muffler bolts on your cylinder. Silver M6x20 are lower muffler bolts, black M6x25 are cylinder bolts.

I don't know why all this grumbling, Oddjob runs nice.

gchamber

ArboristSite Member

For some reason mine will idle and run normal full throttle but and it's a big but if I sit it down and let it idle for a bit then tap the throttle it will die I'm so done with this carb I'm going to break down and get a Tillotson hs-320a.

Sounds like your low adjustment might be slightly off? might try giving it a tweak to the left to see if that helps at all before throwing money at parts. Before my cylinder bolts popped, I had that carb tuned up so so nice, it ran great

MG porting

ArboristSite Guru

IvI' tried its really sesative i ported my cylinder so a better carb is a must.Sounds like your low adjustment might be slightly off? might try giving it a tweak to the left to see if that helps at all before throwing money at parts. Before my cylinder bolts popped, I had that carb tuned up so so nice, it ran great

MG porting

ArboristSite Guru

Never needed one but I've woeked onoa few they are screamers.I got a email. they are going to sell a pop off gauge soon. so no more excuses for building a saw and not testing it. anyone wanna 200t?

smokey7

jack of a lot ace of a few

Im just reading and catching up. Im having a really hard time seeing how the saw that broke the jug bolts would need anything more then a new set of bolts and maybe a gasket. A case and crank with bearings seems way not needed. Im sure the clearance to the transfer tunnels will help it all fit together with no binding and i find it doubtful you will have anynore issues with breaking bolts provided they are getting torqued evenly and to a proper spec. Id bet 25 ftlbs is more then plenty to hold it all together for the long term. I also doubt that using the wrong length (shorter) bolts would cause them to break either. Nice builds guys hope everyone is enjoying the process of building a clean new saw from scratch.

If he can check the torque don't encourage him to over do it.Im just reading and catching up. Im having a really hard time seeing how the saw that broke the jug bolts would need anything more then a new set of bolts and maybe a gasket. A case and crank with bearings seems way not needed. Im sure the clearance to the transfer tunnels will help it all fit together with no binding and i find it doubtful you will have anynore issues with breaking bolts provided they are getting torqued evenly and to a proper spec. Id bet 25 ftlbs is more then plenty to hold it all together for the long term. I also doubt that using the wrong length (shorter) bolts would cause them to break either. Nice builds guys hope everyone is enjoying the process of building a clean new saw from scratch.

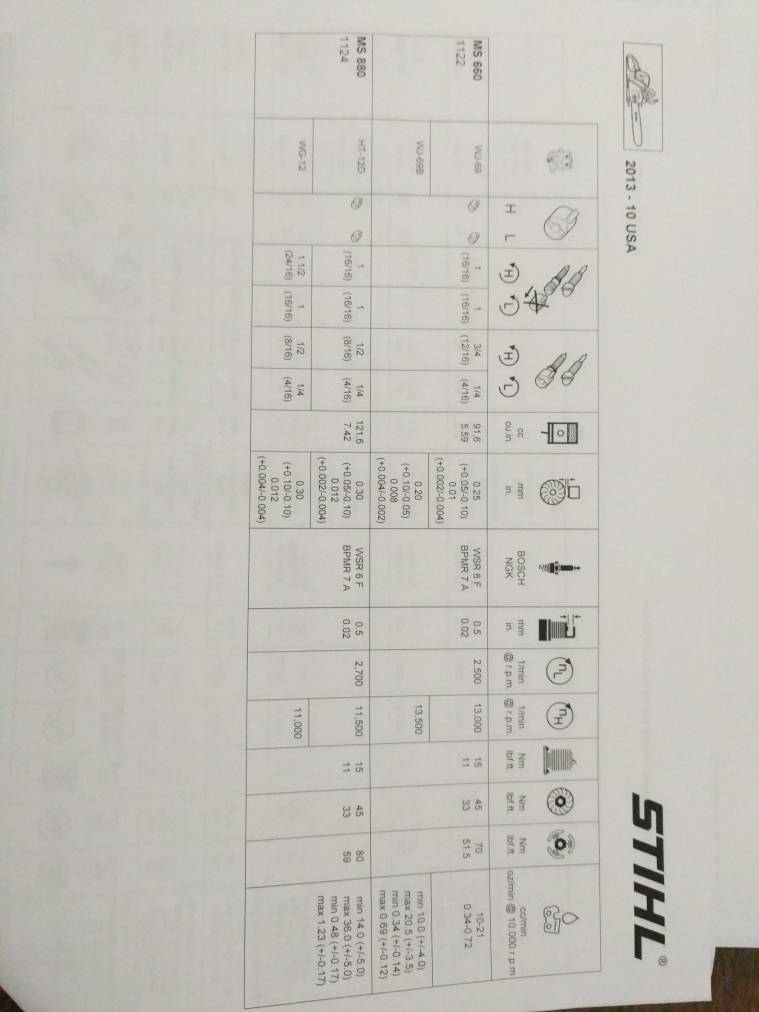

11 ft lb per stihl

gchamber

ArboristSite Member

Pretty sure 11 ft lb is easily achievable. I dont have a 1/4" drive torque wrench though. or a socket small enough to fit down the cylinder fins for that matter, but I don't think the bolts being loose from the get go was the issue. I think the cylinder was pinched against the case not allowing me to tighten the bolts all the way down, then with the vibration and the expanding and cooling from heat cycles, the bolts worked their way out until eventually there was enough room for the cylinder to move up and down, hammering the heads off.

I think Bedford's advise was more of a "replace all this and you'll know for sure it wont be a problem again" instead of me putting the saw back together, running it for an hour or so and then the crank bearing seizing. Either way, my plan is to try to put it back together with new head bolts and see what happens. The gasket isn't bent or creased or anything, so I am going to install it then try to complete a leak down test to ensure proper sealing. Hopefully all good and I can get back to sawing!

I think Bedford's advise was more of a "replace all this and you'll know for sure it wont be a problem again" instead of me putting the saw back together, running it for an hour or so and then the crank bearing seizing. Either way, my plan is to try to put it back together with new head bolts and see what happens. The gasket isn't bent or creased or anything, so I am going to install it then try to complete a leak down test to ensure proper sealing. Hopefully all good and I can get back to sawing!

William Prophett

ArboristSite Operative

I really think it will be fine. One word of caution, and I'm not sure if it will matter or not, the metal base gaskets are "supposed" to be "one time use" gaskets. You have three options here, one is to use the gasket and hope, the second is to use the gasket and coat the surfaces with 1184 (that I do anyway), and third would steal the gasket from the other 54mm cylider (granted thats if you didn't use it the first time). Also, if you did use the kit gasket, did you grind it out for clearance for the 56 (I think I remeber seeing you say you did)... I believe you are exactly right, the clearance issue caused the issue and as the bolts loosened up they got hammered off.Pretty sure 11 ft lb is easily achievable. I dont have a 1/4" drive torque wrench though. or a socket small enough to fit down the cylinder fins for that matter, but I don't think the bolts being loose from the get go was the issue. I think the cylinder was pinched against the case not allowing me to tighten the bolts all the way down, then with the vibration and the expanding and cooling from heat cycles, the bolts worked their way out until eventually there was enough room for the cylinder to move up and down, hammering the heads off.

I think Bedford's advise was more of a "replace all this and you'll know for sure it wont be a problem again" instead of me putting the saw back together, running it for an hour or so and then the crank bearing seizing. Either way, my plan is to try to put it back together with new head bolts and see what happens. The gasket isn't bent or creased or anything, so I am going to install it then try to complete a leak down test to ensure proper sealing. Hopefully all good and I can get back to sawing!

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 32

- Views

- 3K