rms61moparman

Addicted to ArboristSite

Bob, I believe the "airbox" reference is simply where the fuel line comes out where the carb is mounted. Area where the carb is mounted is often referred to as the airbox. It is simply a matter of reference. The top of the hole is the airbox floor, the bottom is inside the fuel tank.

Steve

:agree2::agree2::agree2:

The whole area where the carb draws air from is what they refer to as the "airbox".

Mike

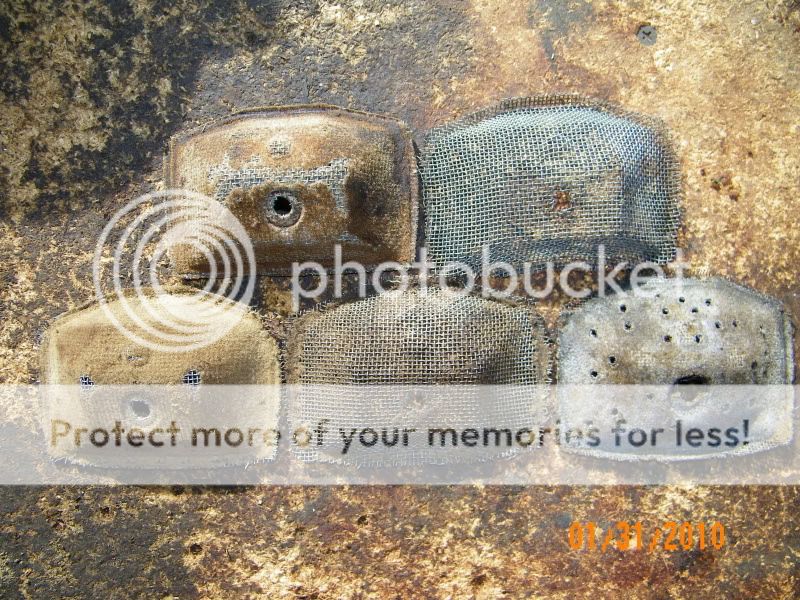

top end is good...

top end is good...