Agree with everything Aaron and Bob said above. You'll occasionally see these saws with a bow saw setup. I has a special brace along with the clutch cover and a couple spacers that space the bar away from the crankcase so the chain clears. Nice setup. Difficult to find a factory setup though.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nik's Poulan Thread

- Thread starter FATGUY

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

XPLRN

Dad ^^^^ wouldn't understand the CAD!!! :-)

It's complete garbage. Send it out west here for orderly disposal.

Seriously though, that is indeed a 74cc saw. Built on the same chassis as the 59cc 306A. Lightweight for 74cc indeed. Robust, strong, and reliable. Air filters and many other parts are getting harder to find, so you'll need to keep that in mind. For an everyday production saw...........look to newer, foreign objects. As a light duty firewood saw and something to have fun with..................it's hard to beat. Looks like you have an earlier one, as it has the 'scrip' model number on the flywheel cover. That's the first 245A I've seen in that style. Other guys here probably have a few of 'em though. I've seen several 306's and 306A's in that style. That 245A will easily run a 24" bar (or even a 28"), but they ballance better with a 20". They'll run a 3/8-8 rim with a 20" bar for more chain speed too. I'd run a 3/8"-7 if mounting a 24" or 28" bar however.

That saw most likely has a governed Tillotson HS carburetor. The governor assembly is a large brass threaded plug on the side of the carb. That governer can make the saw 'seem' to be running richer than it really is. When tuning it, don't go much less than 1-1/8 turn out from seated on the high side. Many of us disable the governer using a disc cut from copper, a beer can, or a welch plug from a carb kit. You unscrew the governer when rebuilding the carb, then put your disc into the governer hole before threading in and tightening the governor body. Put some gasket sealer on the threads of the governor. I wrote down what size punch to use when cutting out the governor disabling disc..........but I left the paper down in the shop. I'll be in there tomorrow morning, and will post the size up here.

Thank-you Eccentric, for the great overview of this saw!! It is something to have fun with and see how it cuts once I get some of the stuff mentioned below taken care of. My 5200 is no where near close to cutting/operational shape so since this 245A is running and fairly close in displacement to the 5200 I'll play with it for now!! Also thanks to redunshee and 67 Mustang for your inputs.....this saw will need a new bar and chain.

I am impressed with now knowing that it is indeed a 74 c.c. saw in that package size. I will like to find a new air filter, carb kit and bar and chain to start getting it in shape. Of course a new fuel line and filter as the fuel line in the picture below sure looks like a replacement candidate.

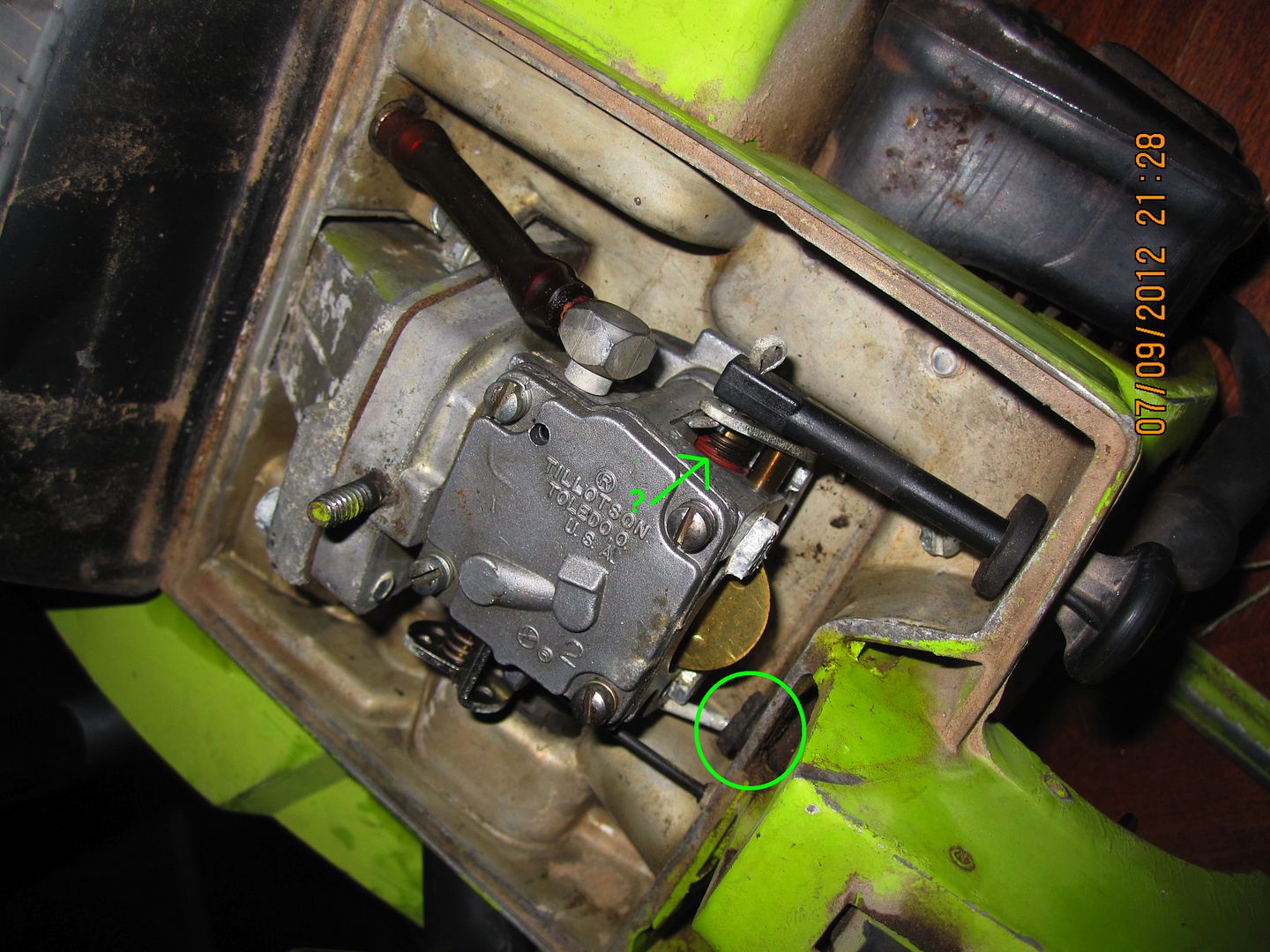

Here is a picture of the carb with a few areas noted;

1st is what I presume to be the "governor" with a arrow pointing to it with a question mark beside it. Appears to have some factory thread sealer around that item. What might be the correct carb kit part number to look for with this carb?? Has anyone written up a post(with pictures) on disabling the governor on this carb?? Of course from your description of the operation is seems pretty basic and something I can figure out once the carb is dis-assembled to clean and kit.

2nd is a circle around a grommet / o-ring style seal around a sliding control rod. That item seems to be pretty whipped out/loose and was wondering what folks have used to replace this?? Seems like it could suck in unfiltered air with that area not getting a good sealing up!??

Last edited:

Eccentric

Mister Wizard

Agree with everything Aaron and Bob said above. You'll occasionally see these saws with a bow saw setup. I has a special brace along with the clutch cover and a couple spacers that space the bar away from the crankcase so the chain clears. Nice setup. Difficult to find a factory setup though.

I'd love to find one of those bow bar setups (with the special clutch cover, the brace, and the spacers) for these saws. I'd put it on a 245A (if it didn't already come with a saw).

Thank-you Eccentric, for the great overview of this saw!! It is something to have fun with and see how it cuts once I get some of the stuff mentioned below taken care of. My 5200 is no where near close to cutting/operational shape so since this 245A is running and fairly close in displacement to the 5200 I'll play with it for now!! Also thanks to redunshee and 67 Mustang for your inputs.....this saw will need a new bar and chain.

I am impressed with now knowing that it is indeed a 74 c.c. saw in that package size. I will like to find a new air filter, carb kit and bar and chain to start getting it in shape. Of course a new fuel line and filter as the fuel line in the picture below sure looks like a replacement candidate.

Here is a picture of the carb with a few areas noted;

1st is what I presume to be the "governor" with a arrow pointing to it with a question mark beside it. Appears to have some factory thread sealer around that item. What might be the correct carb kit part number to look for with this carb?? Has anyone written up a post(with pictures) on disabling the governor on this carb?? Of course from your description of the operation is seems pretty basic and something I can figure out once the carb is dis-assembled to clean and kit.

2nd is a circle around a grommet / o-ring style seal around a sliding control rod. That item seems to be pretty whipped out/loose and was wondering what folks have used to replace this?? Seems like it could suck in unfiltered air with that area not getting a good sealing up!??

That is indeed the governor. The factory sealer on it is hard/brittle and will be ineffective once you unscrew the governor. You can use a little bit of Threebond 1194 or some permatex hi-tac or Indian Head sealer on the governor body threads. Just don't put so much on that it runs into the governor passages (and into the carb body) as you're assembling it. There have been posts (in this thread plus a few others) and 'stand alone' threads on disabling the governor on Tillotson HS carbs. You can find them with a google search. It's pretty basic, and you can do it with the info I've already given you however.

The carb kit you need is the common Tillotson RK-23HS. Easy to find and cheap.

I don't know whether that grommet is still available from Poulan/Husky. I'll probably make ones for my saws out of pieces cut from B&S filter foam glued to the carb box, or something similar.

Poulan 3400 carb problems

I've got a 3400 that hadn't been run in a while, and put in a carb kit. It started and ran for a couple of days and then would only start/run with the choke on. Took the carb back apart, cleaned it in the USC, and reassembled it. Now it'll start, and idle (sort of), but wants to die as soon as the trigger is squeezed. It also is spraying gas out the top of the carb, onto the handle. Any ideas????

I've got a 3400 that hadn't been run in a while, and put in a carb kit. It started and ran for a couple of days and then would only start/run with the choke on. Took the carb back apart, cleaned it in the USC, and reassembled it. Now it'll start, and idle (sort of), but wants to die as soon as the trigger is squeezed. It also is spraying gas out the top of the carb, onto the handle. Any ideas????

I'd love to find one of those bow bar setups (with the special clutch cover, the brace, and the spacers) for these saws. I'd put it on a 245A (if it didn't already come with a saw).

That is indeed the governor. The factory sealer on it is hard/brittle and will be ineffective once you unscrew the governor. You can use a little bit of Threebond 1194 or some permatex hi-tac or Indian Head sealer on the governor body threads. Just don't put so much on that it runs into the governor passages (and into the carb body) as you're assembling it. There have been posts (in this thread plus a few others) and 'stand alone' threads on disabling the governor on Tillotson HS carbs. You can find them with a google search. It's pretty basic, and you can do it with the info I've already given you however.

The carb kit you need is the common Tillotson RK-23HS. Easy to find and cheap.

I don't know whether that grommet is still available from Poulan/Husky. I'll probably make ones for my saws out of pieces cut from B&S filter foam glued to the carb box, or something similar.

This reminds me, I have to do this to my 245A.

I'd love to find one of those bow bar setups (with the special clutch cover, the brace, and the spacers) for these saws. I'd put it on a 245A (if it didn't already come with a saw).

That is indeed the governor. The factory sealer on it is hard/brittle and will be ineffective once you unscrew the governor. You can use a little bit of Threebond 1194 or some permatex hi-tac or Indian Head sealer on the governor body threads. Just don't put so much on that it runs into the governor passages (and into the carb body) as you're assembling it. There have been posts (in this thread plus a few others) and 'stand alone' threads on disabling the governor on Tillotson HS carbs. You can find them with a google search. It's pretty basic, and you can do it with the info I've already given you however.

The carb kit you need is the common Tillotson RK-23HS. Easy to find and cheap.

I don't know whether that grommet is still available from Poulan/Husky. I'll probably make ones for my saws out of pieces cut from B&S filter foam glued to the carb box, or something similar.

That grommet is actually called a throttle boot and it for sure is NLA. Heck its so old it uesed a 4 digit part #, 2597.

Good luck in finding one, there ought to be somthing a guy could make up though and it is definitly needed to keep the dirt out of the carb box, under the filter.

I hate to say it but I do have a few NOS boots but with as many of those series saws that I have, no way could I let one go......

BTW, the carb is not that hard to remove if you have done it a few times, and you have the right tool to use. My idea of the right tool is a Craftsman 5/16" boxed end ign wrench with the box end ground down as thin as you dare go with it.

It will slip right in on the lower carb bolt that way and make the job much easier.

Last edited:

$21.99 ($3.66 / Count)

Firewood Log Splitter 45mm+32mm + 4 Handles (Square + Round + Hex Shank + Small Hex) Wood Log Splitter Easy Splitter Detachable Drill Bit Heavy Duty Electric Drills Screw Cone Driver Removable

JianShiMoQinDianZiShangWuYouXianGongSi

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$56.99 ($0.38 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$56.99 ($0.38 / Foot)

$59.99 ($0.40 / Foot)

Double Braid Arborist Rope Orange(1/2 in x 150 ft) Arborist Rigging Polyester Rope - 48 Strand Rope Swing for Tree Bull Rope for Outdoor, Climbing, Swing, Sailing

Cosirulnta Shop

$59.99 ($0.40 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$14.99

$17.99

Fiskars Pole Saw Blade Replacement for Fiskars Pruning Saws and Tree Pruners, 15" Blade with Woodzig Chainsaw-Style Tooth Design

AMZ South Supply

$39.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

TA edition 3750 rebuilt again and cutting.

3rd one and worst condition one I have had. This one had a freaking bowsaw on it at one time and owner grind on crankcase side to fit. :msp_rolleyes:.

today finished again

in past rebuild

3rd one and worst condition one I have had. This one had a freaking bowsaw on it at one time and owner grind on crankcase side to fit. :msp_rolleyes:.

today finished again

in past rebuild

Kev, that might not be the prettiest 3750 but it aint so ugly it has to sneak up on the trees. :msp_rolleyes:

How she run?

How she run?

Mark now that right there was funny. :hmm3grin2orange:

Runs just like the other 2 did. Right on the skirt of a 262 IMHO. :msp_tongue:

Runs just like the other 2 did. Right on the skirt of a 262 IMHO. :msp_tongue:

Mark now that right there was funny. :hmm3grin2orange:

Runs just like the other 2 did. Right on the skirt of a 262 IMHO. :msp_tongue:

Pretty much just the way I figgered it would! Thats saying something as well.

I've got a 3400 that hadn't been run in a while, and put in a carb kit. It started and ran for a couple of days and then would only start/run with the choke on. Took the carb back apart, cleaned it in the USC, and reassembled it. Now it'll start, and idle (sort of), but wants to die as soon as the trigger is squeezed. It also is spraying gas out the top of the carb, onto the handle. Any ideas????

Had the same issue with my 026.

Are the gaskets and diaphrams in the right order?

You should also pressure test the carb.

Got this info from Zippy and it was a big help.

Use around 7 psi to test. Walbro says it's OK to have a few bubbles coming out.

You can put the carb in a glass of water when you pressure test it to try and see where it's leaking from. If the bubbles come out of the Venturi it's most likely the needle valve, if they come out the impulse channel it's probably the pump diaphragm and if they come from the hole in the metering side lid it's the metering diaphragm.

Moparpoulan

ArboristSite Lurker

Think I got burned

So does anyone know if this will affect the performance of the saw, I have never had a saw with this issue until I bought thisView attachment 244710

So does anyone know if this will affect the performance of the saw, I have never had a saw with this issue until I bought thisView attachment 244710

Had the same issue with my 026.

Are the gaskets and diaphrams in the right order?

You should also pressure test the carb.

Got this info from Zippy and it was a big help.

Use around 7 psi to test. Walbro says it's OK to have a few bubbles coming out.

You can put the carb in a glass of water when you pressure test it to try and see where it's leaking from. If the bubbles come out of the Venturi it's most likely the needle valve, if they come out the impulse channel it's probably the pump diaphragm and if they come from the hole in the metering side lid it's the metering diaphragm.

Thanks! I'll give it a try......

wigglesworth

Booned

redunshee

Addicted to ArboristSite

I've got a 3400 that hadn't been run in a while, and put in a carb kit. It started and ran for a couple of days and then would only start/run with the choke on. Took the carb back apart, cleaned it in the USC, and reassembled it. Now it'll start, and idle (sort of), but wants to die as soon as the trigger is squeezed. It also is spraying gas out the top of the carb, onto the handle. Any ideas????

Assuming you have the diaphragms in the correct order, I'd say your metering lever is too high. It should be set level with the carb body before you install the gasket and diaphragm( in that order). Exact opposite order on the pump side. I'd then set the Lo and HI needles at 1 turn out from lightly seated and adjust the Lo needle richer( counterclockwise) until saw accelerates smoothly. I usually let saw warm up at idle and turn LO needle in until saw starts to die, then open it up until it again starts to die. Midway between the two extreme settings is usually where it needs to be.

Bob

So does anyone know if this will affect the performance of the saw, I have never had a saw with this issue until I bought thisView attachment 244710

Probably not immediately but definitely will hurt the cooling of the cylinder. I would keep on the lookout for another cylinder. You kinda wonder how used equipment got that way...

homelitejim

Full of Scrap

So does anyone know if this will affect the performance of the saw, I have never had a saw with this issue until I bought thisView attachment 244710

looks like they tried to change the spark plug with a sledge hammer. A fin or two is no big deal but that there can cook your saw quick.

rms61moparman

Addicted to ArboristSite

So does anyone know if this will affect the performance of the saw, I have never had a saw with this issue until I bought thisView attachment 244710

Well you know, it's like this right here.

I wouldn't knowingly pay top dollar for that saw.

If it was an ebay saw I would file a dispute.

That being said, you have the saw, and if you get two hours of cutting or ten years of cutting, it won't hurt anything MORE than the piston and cylinder.

I personally would run the scoundrel like it belonged to my brother in law!!!

You may be surprised how much cutting it will still do.

JMHO

Mike

I'd then set the Lo and HI needles at 1 turn out from lightly seated and adjust the Lo needle richer( counterclockwise) until saw accelerates smoothly.

Bob

Check that the needles aren't damaged or bent which would prevent proper seating. This can happen if they've been overtightened.

Check that the needles aren't damaged or bent which would prevent proper seating. This can happen if they've been overtightened.

Another thing, I forgot to mention, was that it would still run with both needles adjusted ALL the way in.......

Similar threads

- Replies

- 2

- Views

- 579