Well fellow sawdust flingers and chip throwers, it's been a while since I put anything into the thread, but I've seen a lot of forum traffic regarding this genre of saw in my lurking--the venerable Roper 3.7 I've used a ton of saws out of my pile, but I keep coming back to the 3.7. It has an excellent balance with a 20" bar pulling 3/8" pitch, it has enormous power, and it just has a unique sound thru big wood 4 strokin' at WOT. I imagine folks have read thru my Stihl tophandle thread, and the MS660 etc, but I keep coming back to the Ropers. I have 3 of these here, all screaming and throwing chips, and a 4th sent to my son in WA state so he can get firewood and spread the virtues of this saw.

I did some cutting this past week for a buddy, since I have now retired after 38 years Active Army federal service including 4 combat tours, so I find time to help out my buddies with vertical trees who desire them horizontal. Loan of a chainsaw from me includes me, saws, and a truck that is as equally and gloriously spavined as I am. 86 Toyota 4 X 4, approaching 200K miles, never lets me down. So I brought down a Lychee tree, these can be pretty big with many accessory trunks and are always packed in closely to several homes that generally look to be tear-downs though with high occupancy levels. Lychee bear a very unique fruit that is killer when you can get it, but this tree has never produced while the adjacent buddy tree put out choke Lychee. Barren tree is coming down to make room for Mango, or Avocado, or bananas. Came down I should say, as it is now in smaller sizes in my back yard and I'm using appropriate sized chunks for smoking meat that I don't want to be overpowered by Keawe smoke. Lotta smoking of large slabs of dead animals here lately. Axis Deer, Briskit, Salmon I caught in AK, whole chickens, Taco/He'eh/Octopus, Turkey, feral pig, maybe some roadkill mongoose.

So what does this all have to do with the Roper story? Eh? If you're Canadian, "what's this all aboot now?

My bar/chain oiler wasn't working right on my primary 3.7, so I had to set it aside and use the husqvarna closed port 55 Rancher, and the Stihl tophandle 015L. The little Stihl decided to show me that gas was mixing across the fuel reservoir into the bar lube reservoir and vice versa, so that little saw had to get put aside as well as it quit running trying to combust bar lube instead of 2-stroke mix oil, and I don't think the gas/mix thinned bar lube was quite doing the trick either. That saw has now been torn apart once again and I laid Yamabond on both sides of the gasket and put it back together to cure a few days before a test run.

My Roper oiler quit oiling though, and that is disturbing as it has both an automatic adjustable volume, as well as a manual function for supplementation of volume. There are 3 copper fittings/3 copper lines associated with this Roper 3.7 oiling system, and it is a bit complicated. I've read a ton of other threads with some of our forum's finest offering help on this topic, and hopefully they'll pitch in on mine. I'll just throw in my theory and a ton of photos. How's that?

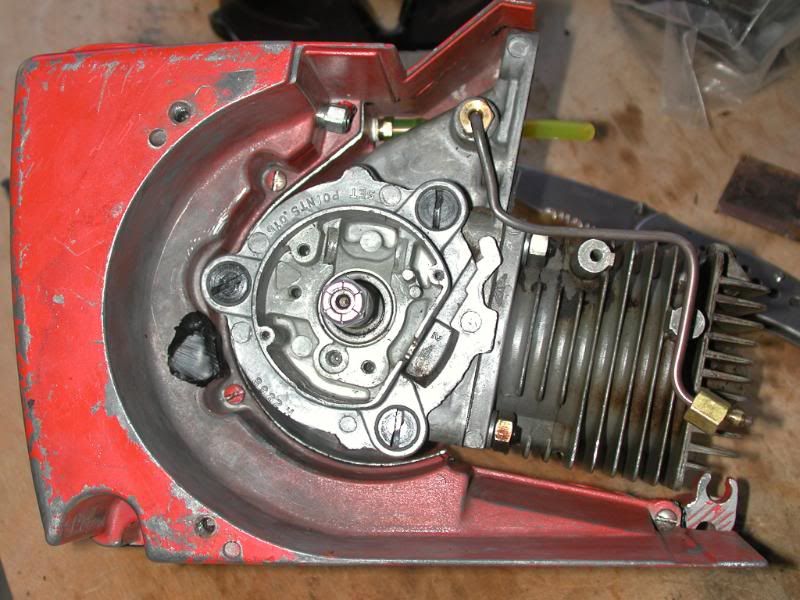

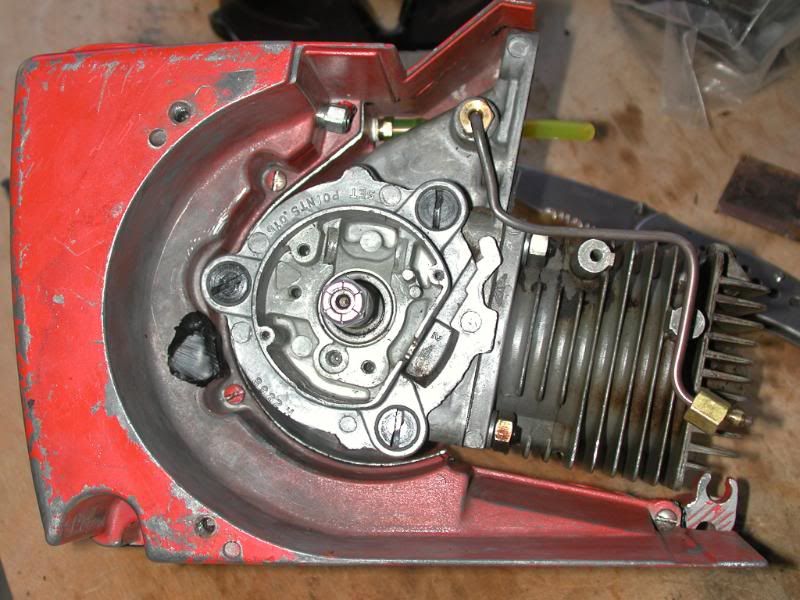

You're looking from the right side of the saw, under the airbox. You can see one copper line, between bottom of the oil reservoir, up to the air box, and it goes to the valve you'll see in the next photo. As you depress the throttle trigger, it simultaneously opens this valve, and in what I can figure out it allows case pulse pressure to provide some pressurization of the oil tank thru a separate copper tube; valve shown here now inside the air box, connected with the trigger.

Valve in the lower left corner, inside the airbox.

This shot below is the opposite side of the assembly as I showed in the first photo in this post. You can see the valve in the box, though disconnected, (wait, it's not really there, just hallucinate it as I don't have a better photo loaded) and can see the round black knurled increase or decrease twist knob for oil flow, and the mostly square (Okay, it's a rhomboid, maybe better to just say it is a truncated triangle) black thumb press button that I love so much to squoosh out extra oil as I need it, and of course, I suppose I do over oil.

This saw though was getting no oil either auto or manual, and it wasn't from clogs in the pipes or problems with the bar and bar mount cover as I can tell.

So here is the pulse line below, it goes into the middle nipple in the oil tank.

And the oil feed line itself is here, the portion visible is going under the pulse line, and continuing forward in the case and pops out on the right side of the saw.

Oil feed line visible here on right side of saw where it pops out from the opposite side of the case, just behind and slightly above the rear most bar mount bolt. No hallucination required.

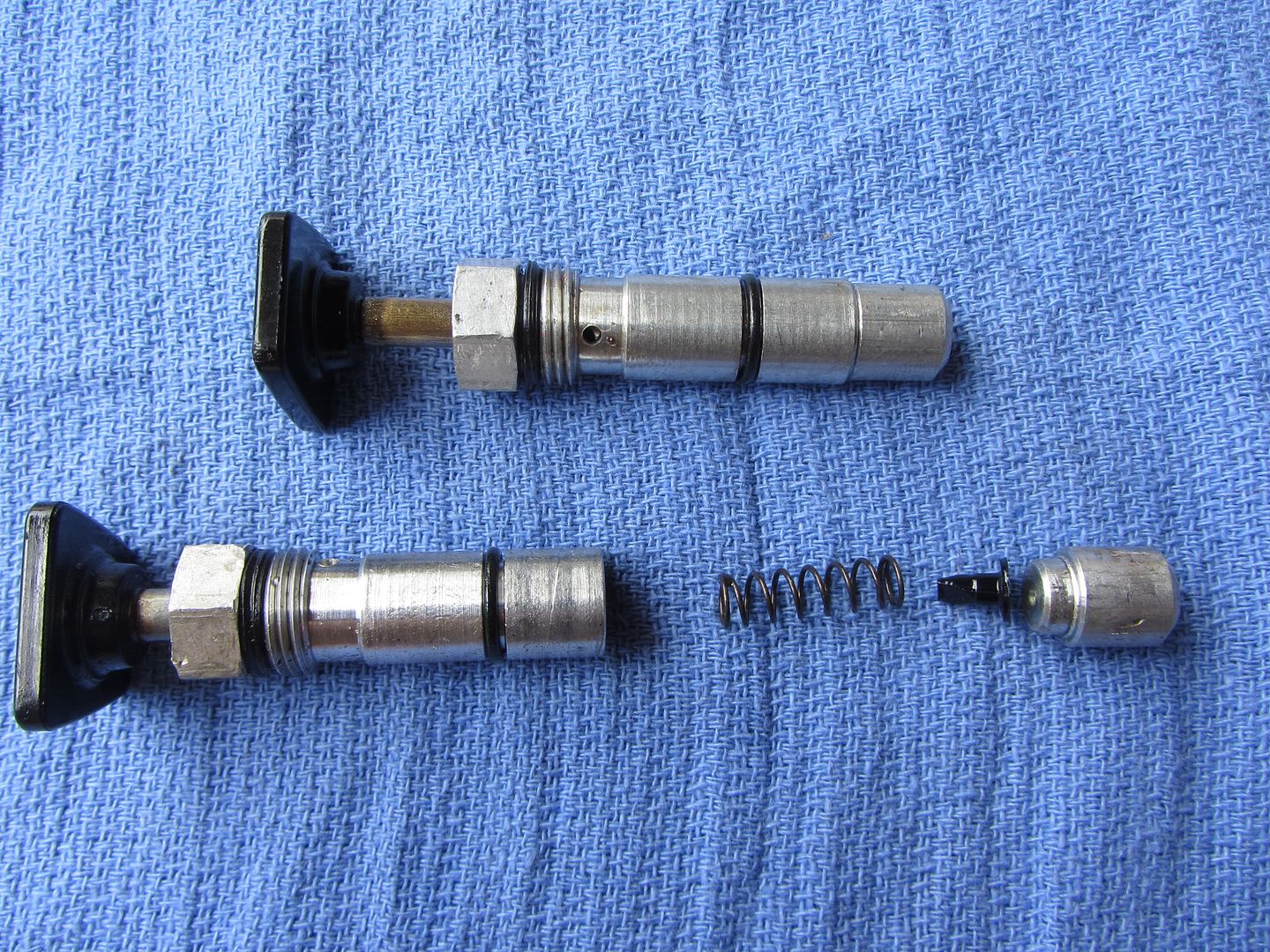

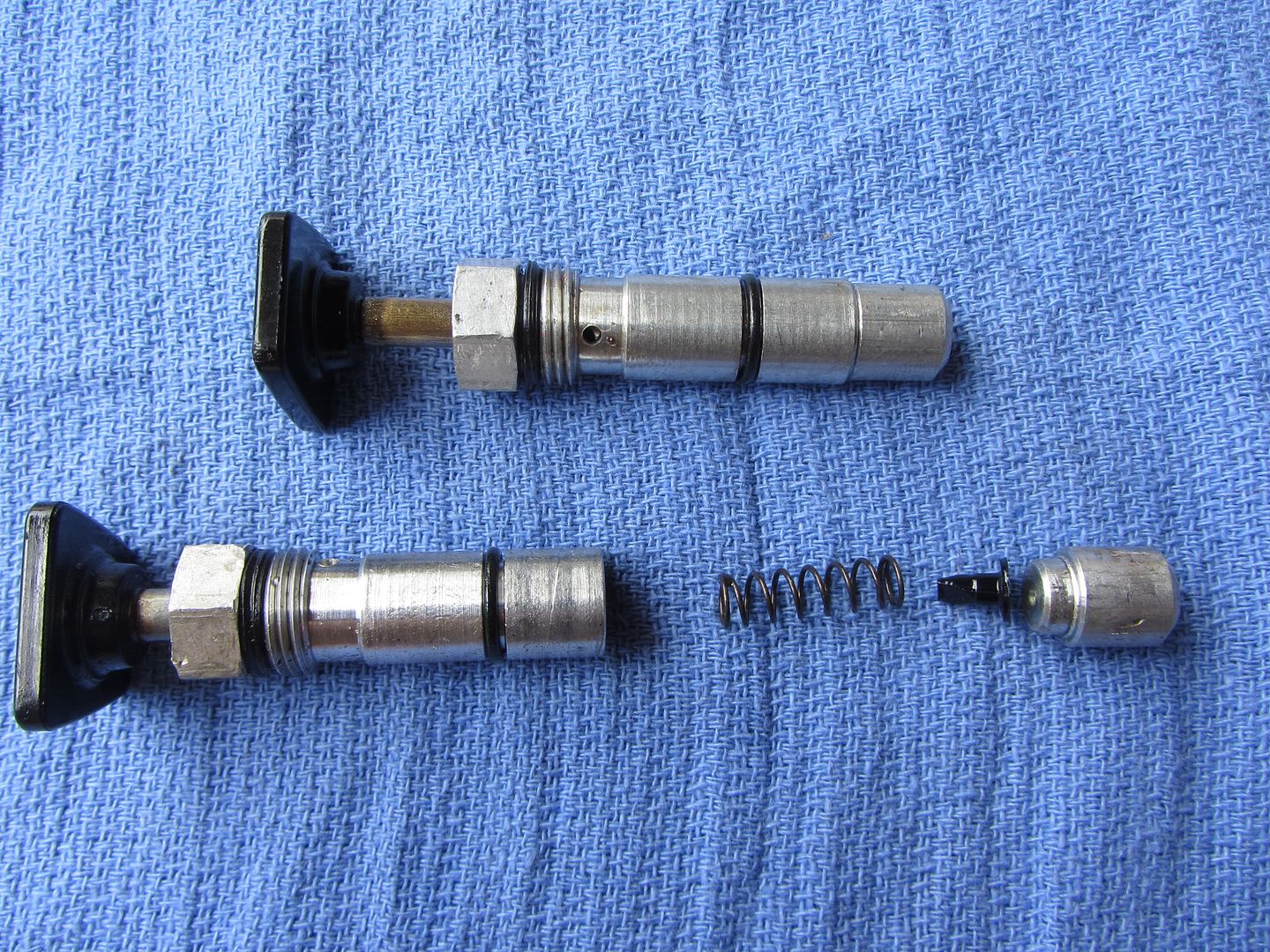

So when you remove the oil pump itself, it looks like this one in the top part of the photo, one from another of my 3.7s.

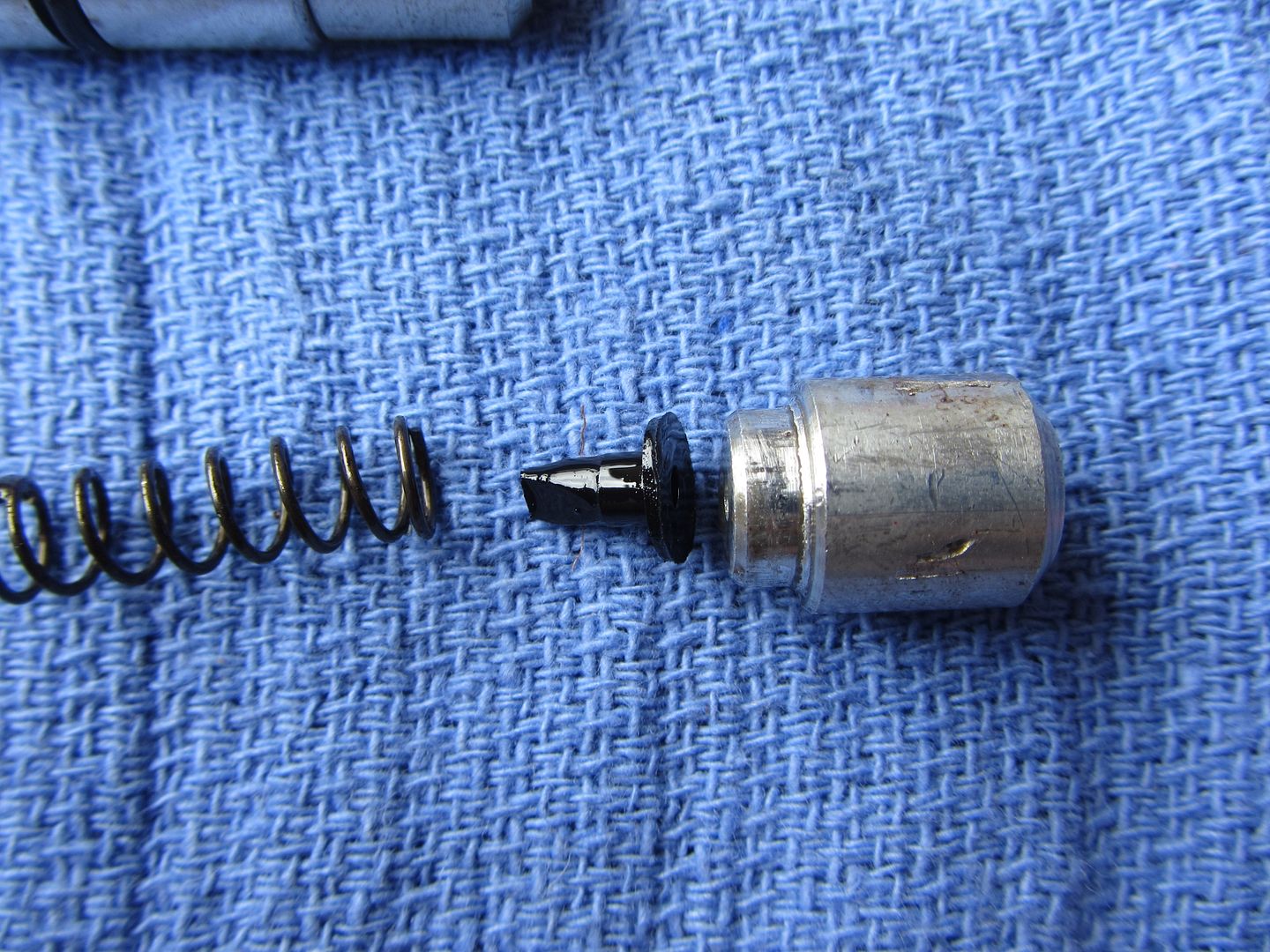

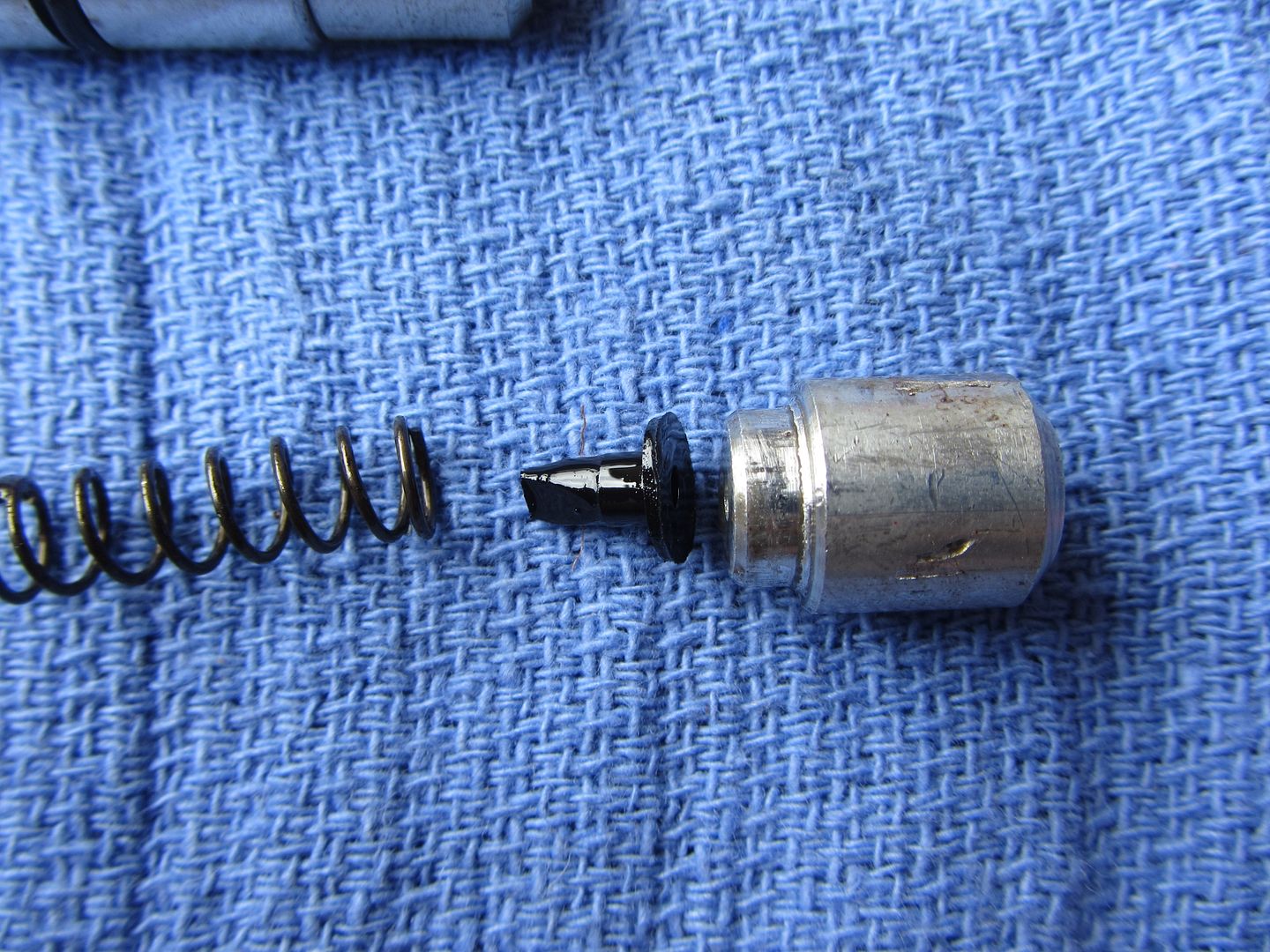

The bottom portion/cap twists off, does not unscrew, and reveals a return spring for the plunger, and a small flanged duckbill check valve.

So as it turns out, my duckbill check valve no longer checks, and I'm getting no lube to my bar/chain. Does anyone perhaps have knowledge of a source for a substitute flanged duckbill checkvalve? That cap on the bottom of the pump merely presses/taps back into place, and the pump unit can then be screwed back into its position. I'd appreciate if anyone has some input on this. While I can swap my one working pump back and forth between these 2 saws, I'd really rather have the both of them fully working as these are the ones I rely on the most. Maybe my benefactors Roanoker494, 67L36Driver, Hotshot, etc will come to my rescue once again.

These Ropers are really awesome saws. If the house caught fire I'd grab that one over the others.

These Ropers are really awesome saws. If the house caught fire I'd grab that one over the others.