BTW I think the carb I used was from a 2-stroke snow blower...something with a tecumseh 2-stroke...I think??

j

j

LOL not yet, It's sitting on the bench as we speak. I've been busy building a pinewood derby car and helping my son with his.

j

Great & classic thread for the 3.7 Roper fans

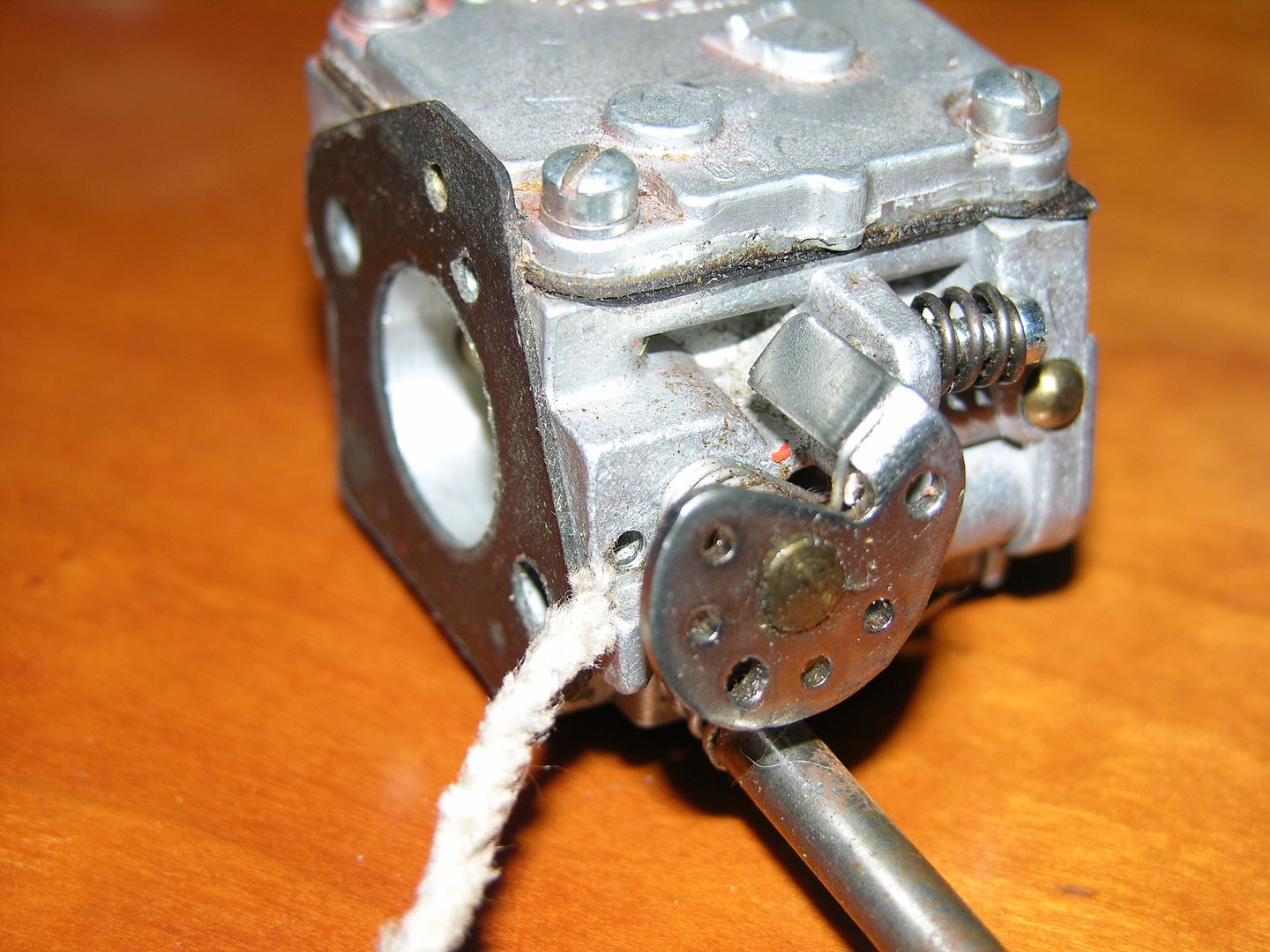

Just curious with a couple of questions, but what was the original Tilly number for the carb that

had only the low speed adjuster (fixed high)? Looks like, from reading through the posts, that

you never did use that one.

Have the thinner metric 1.5mm thick piston rings, versus domestic 1/16" for a 0.0035" difference,

given you any problems on high speed operation (floating)?

I have routinely used the 1.5mm thick rings in a number of saws that originally had the 1/16". I have not noticed any difference in operation. They don't seem to develope as much compression as one would like but, it is the only game in town.

Rings notched for the 1/16" dia. locator pin will develvope great compression. .005" end gap vrs. .070", a no brainer.

I have gotten upwards of a dozen sets from "The Greek" on ebay over the past year.

One of the parts saw I used to get a runner with had a HS79A on it. It is the same style carb as the original with both H/L adjustments.

I'll have to look when I get home. I think I understand what hole you're mentioning. In the view of your photo it looks like a dimple, on the side of the carb, inline with the throttle shaft with the spring. Tiny hole like 1/16 size or so. I'll check mine out when I get home.

I think this represents a hole to allow a minimum required amt of air thru for initial combustion while the choke is fully closed. Sort of akin to that little hole thru the base of your automobile thermostat that lets just a bit of water thru if the open/close mechanism is frozen up. Not going to pontificate more for if this doesn't post this time my puter goes into the pond.

Enter your email address to join: