Another member here made a roadtrip and came back with some awesome saws. I ended up with this DA-211, and it was still only the 2nd coolest saw in the bunch. I'll let him elaborate if he chooses.

Now, I've always maintained that a KB-7 is only 2-man saw I'd ever want to own. However, 67Mustang Steve brought his 211 to the Poulan GTG and after hearing that thing in the cut, I added it to my list, albeit 2nd place.

Anyways, the picture showed it missing some parts and hard-to-find ones at that. Fortunately the seller dug thru his barn and found nearly all of them in a box. Far as I can tell, the only thing missing (aside, possibly, from assorted screws) is the rear handle crossbar with the throttle levers. The saw turns over with fair compression, nothing broken and nothing rotted away. I see the rear handles are a bit tweaked but that will be easy to straighten.

Yes, that is a Pioneer 750 hiding behind the bar.

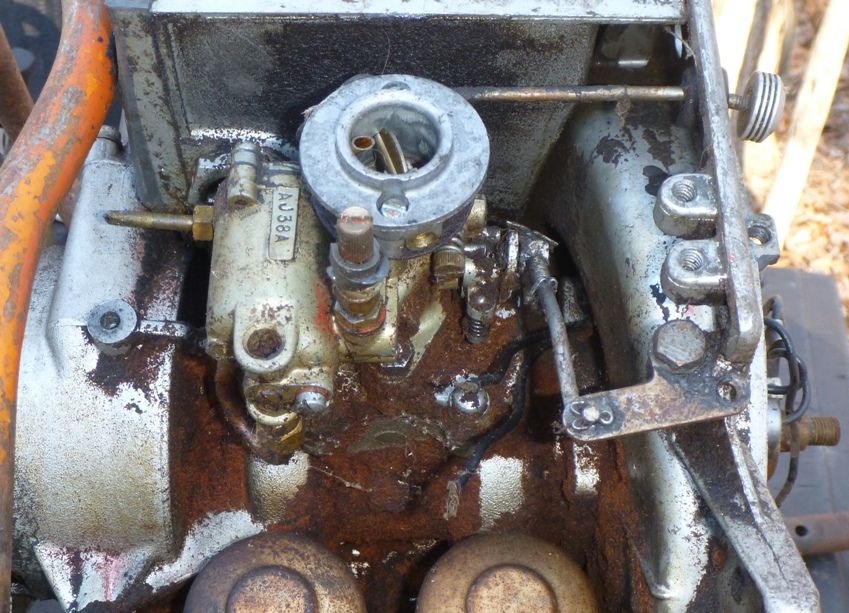

Missing the throttle levers and tube:

Now, I've always maintained that a KB-7 is only 2-man saw I'd ever want to own. However, 67Mustang Steve brought his 211 to the Poulan GTG and after hearing that thing in the cut, I added it to my list, albeit 2nd place.

Anyways, the picture showed it missing some parts and hard-to-find ones at that. Fortunately the seller dug thru his barn and found nearly all of them in a box. Far as I can tell, the only thing missing (aside, possibly, from assorted screws) is the rear handle crossbar with the throttle levers. The saw turns over with fair compression, nothing broken and nothing rotted away. I see the rear handles are a bit tweaked but that will be easy to straighten.

Yes, that is a Pioneer 750 hiding behind the bar.

Missing the throttle levers and tube: