Getting sick of my pictures yet?? Hope not, since I do respect the input of the forum to my questions and issues.

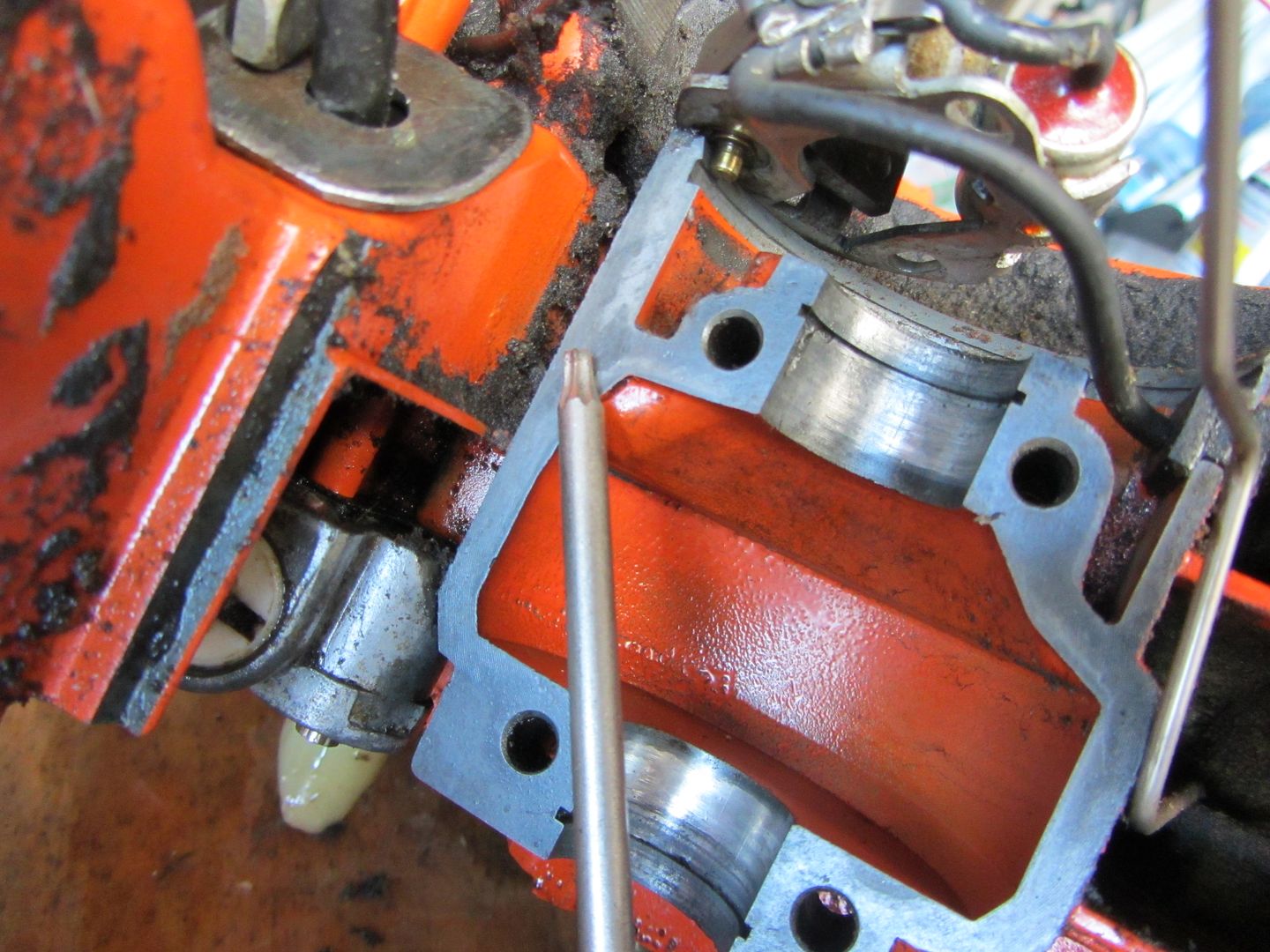

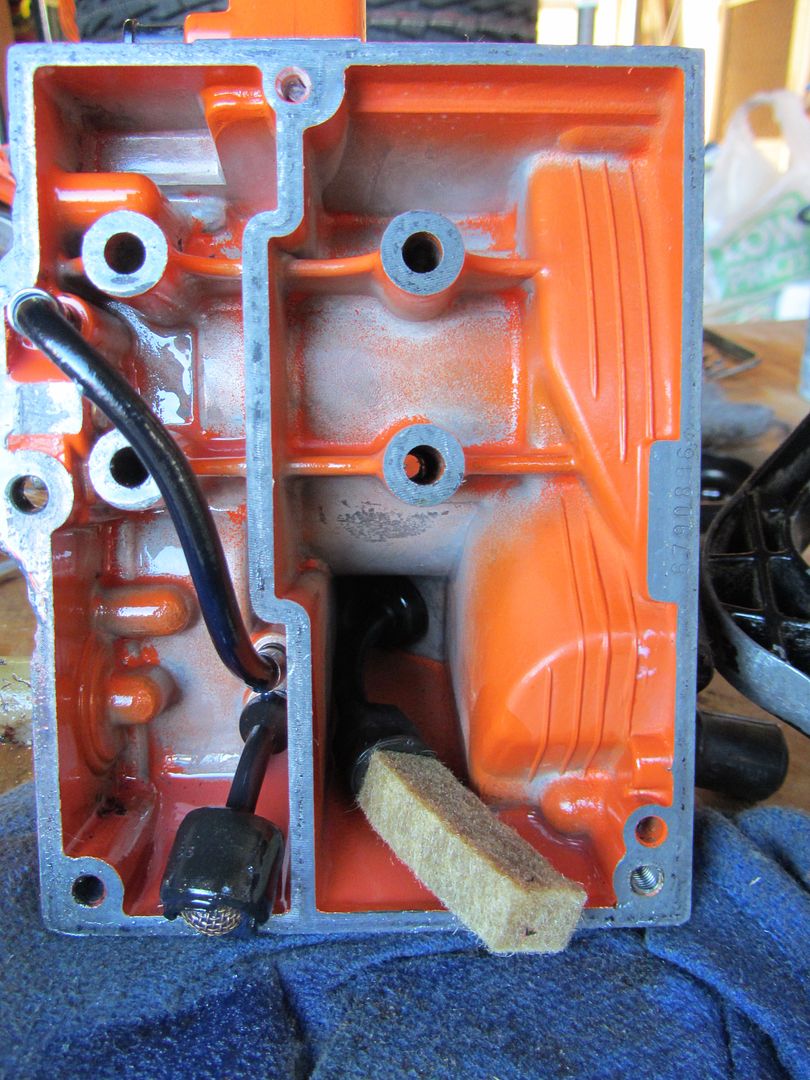

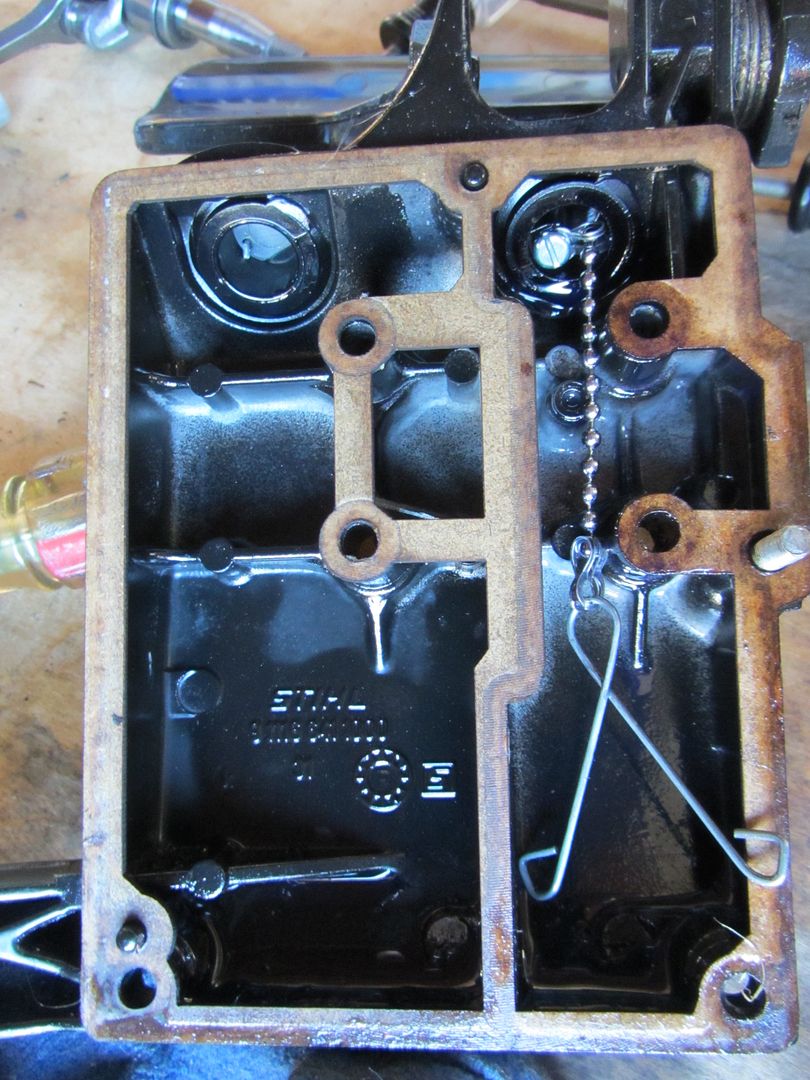

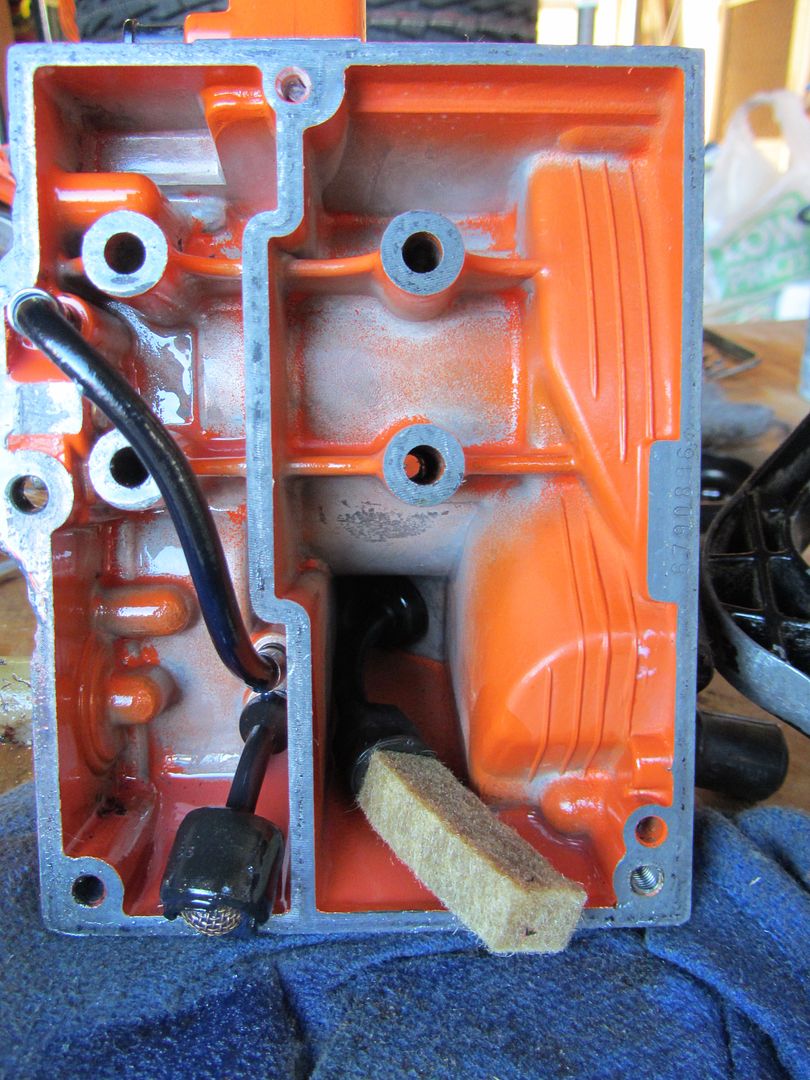

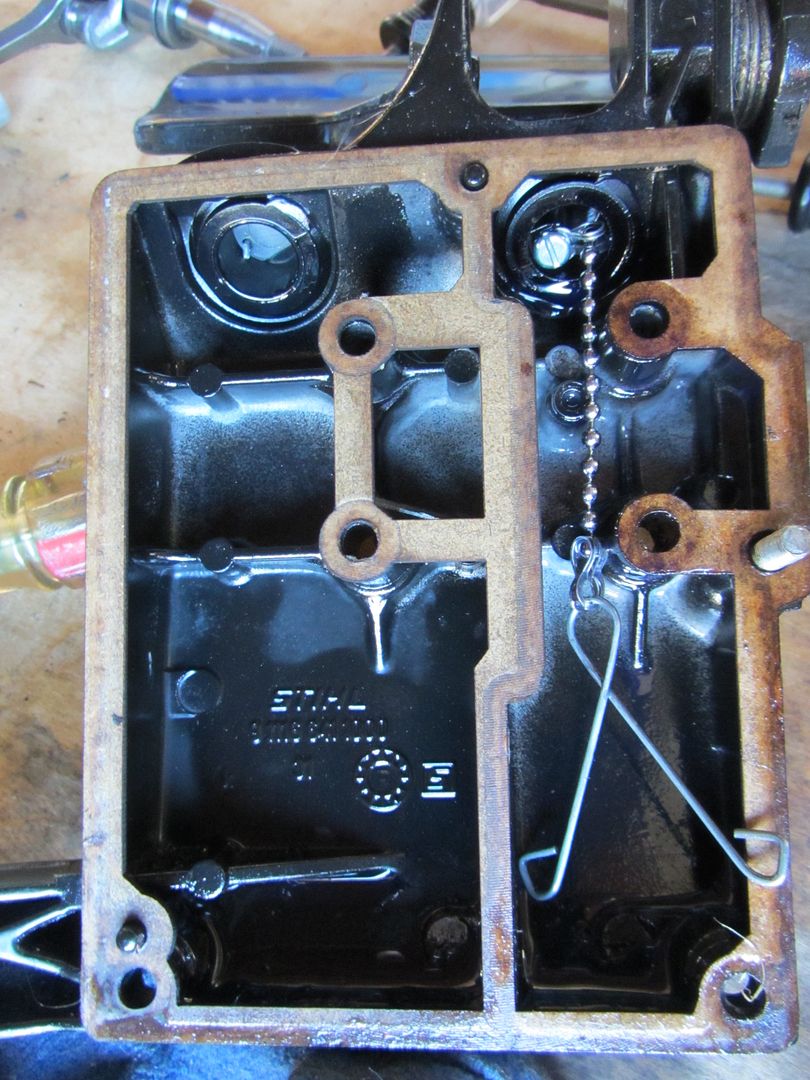

Fuel/Chain oil tanks, the gasket here looks fine, I will likely gum it down with some gasket sealer before I put it back together, unless told to just put it together dry. There was no leakage apparent before I took it apart, and I had lube and fuel mix in it for a week before I tore into it.

And of course, the obligatory pile-O'-parts on the table from the work in progress.

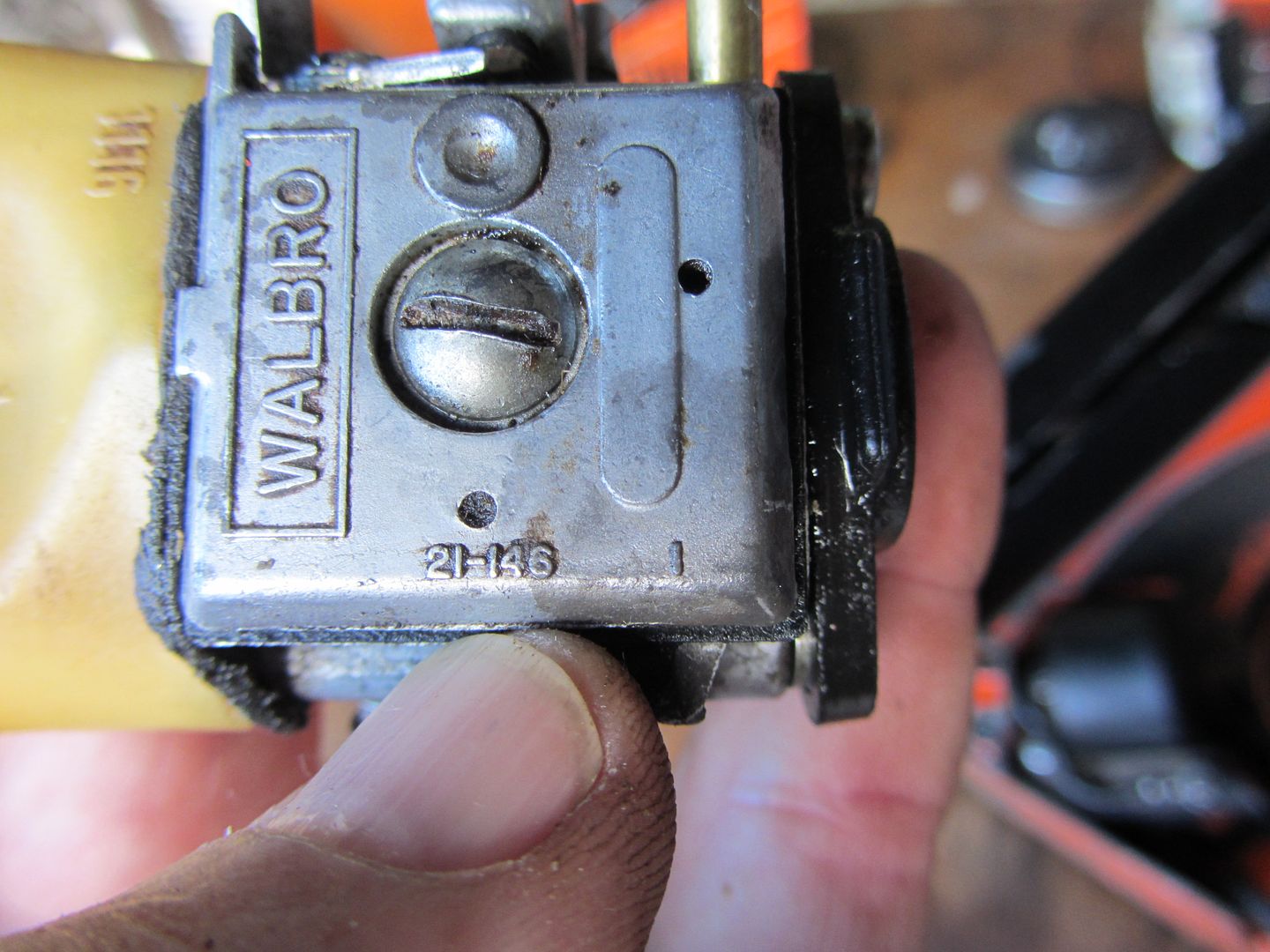

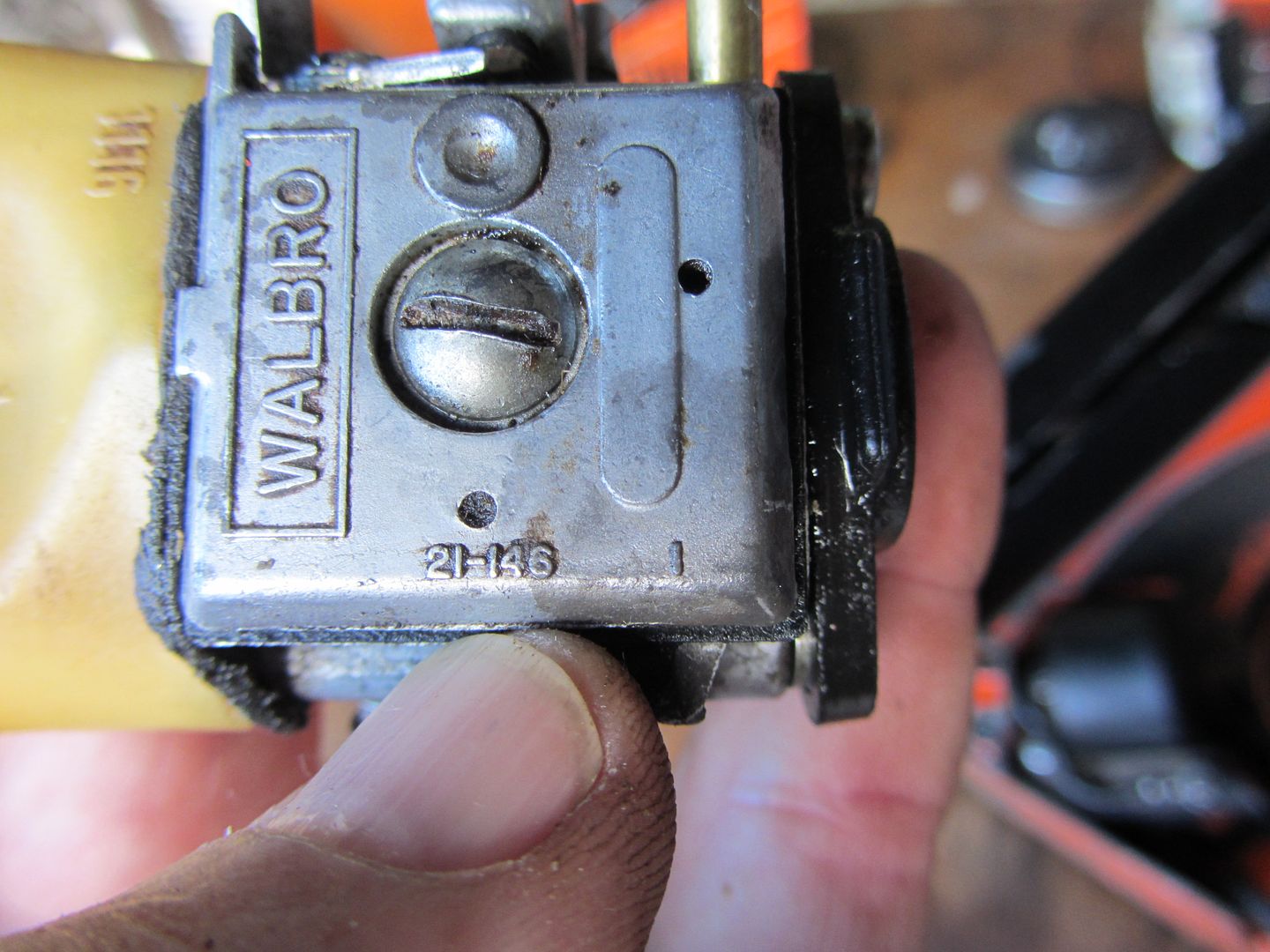

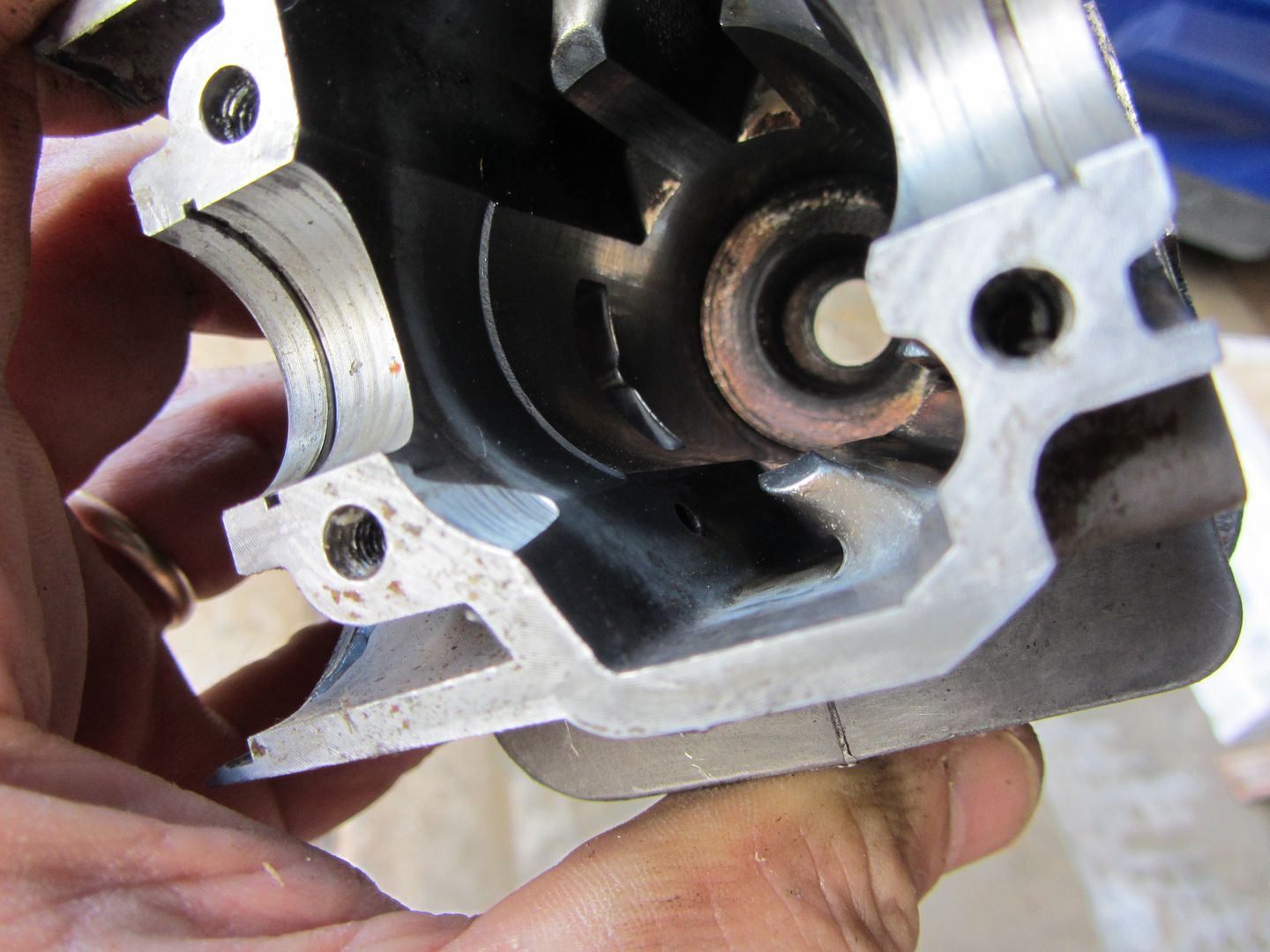

So I'm happy to hear your thoughts on all the above posts. What I will be doing will be to clean up all the parts I have prior to placing hopefully only one order for new parts sometime early next week so I can get this puppy back together. The initial problems I noticed with this saw was that it would idle, but would not rev, and had compression of 70 psi. I am concerned that there should be a case-cylinder gasket which appears to be non-existent. There is some PO modified bracket inside and the mystery bolt holding it in place, I think the piston/bore/ring is fine, and I need to verify my ID of the Walbro carburetor and figure out the points gap. Somewhere I read 19 thousandths but need confirmation.

My parts I feel I need to order at this point is the fuel line/filter, carb rebuild kit, and gasket between crank case and cylinder.