Your time and dinero is better spent on an Echo CS341 type. They have antivibe. And, parts availability.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stihl 015 Tophandle

- Thread starter Opihi59

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Opihi59

ArboristSite Operative

Maybe for the next saw, so long as The Dragon Lady doesn't shut me down.......The only Echo I have is a string trimmer. I don't know a lot about Echo saws. Maybe a little Mac?

So 1/8 Infantry was 3rd BDE wasn't it? I was in HHC 1ST BDE 4ID for 2 years back in the 80's (1/10th, 2/12th, 3/68 AR and 44th Engr). Brigade Staff position, I was the Brigade Surgeon back then, lived in Castle Rock and drove down to Carson and back every day for 2 years. I am still in contact with the BDE CO from that time who made 3 stars and then retired. Ken Casey was the 1/10 Infantry CO then as an 0-5, ended up as Army COS, and I bumped into him again at West Point in 2009. 4th ID was an interesting part of my career in the Army which is rapidly running down to a close now, and of course is no longer interesting.

There aren't a lot of saws out here on the islands, I likely have the biggest pile or functional saws from a collector perspective but I am always looking for more interesting/unique saws from where ever. If an Echo top handle comes my way I likely won't turn it down. Hell, I can't imagine turning down any saws.

So 1/8 Infantry was 3rd BDE wasn't it? I was in HHC 1ST BDE 4ID for 2 years back in the 80's (1/10th, 2/12th, 3/68 AR and 44th Engr). Brigade Staff position, I was the Brigade Surgeon back then, lived in Castle Rock and drove down to Carson and back every day for 2 years. I am still in contact with the BDE CO from that time who made 3 stars and then retired. Ken Casey was the 1/10 Infantry CO then as an 0-5, ended up as Army COS, and I bumped into him again at West Point in 2009. 4th ID was an interesting part of my career in the Army which is rapidly running down to a close now, and of course is no longer interesting.

There aren't a lot of saws out here on the islands, I likely have the biggest pile or functional saws from a collector perspective but I am always looking for more interesting/unique saws from where ever. If an Echo top handle comes my way I likely won't turn it down. Hell, I can't imagine turning down any saws.

Opihi59

ArboristSite Operative

So just a minor update, carb D/G kit arrived today with the new fuel line and filter from L'il Red Barn. I haven't yet even got a "your package has shipped" from the Greek yet for my new ring. Of course, I'd like to get the ring so I can put it all back together and only then have to fool with the fuel line/carb, but suppose I'll be waiting for a bit. The previous ring orders I have got from the Greek really showed up quickly. If it gets here at least by Saturday, I'll play with it all and be able to send more updates and photos, otherwise, I'll be working on the backsplash tile on the kitchen remodel..........

I'd rather make noise though, with the saw.

I'd rather make noise though, with the saw.

drf255

BAD CAD

Subscribed.

I have the same saw apart in a box. Purchased off eBay that way. Interested in your build.

What type of paint will you be using?

IMHO, MUCH cooler than the echo model. And I have a CS330 that I love.

I have the same saw apart in a box. Purchased off eBay that way. Interested in your build.

What type of paint will you be using?

IMHO, MUCH cooler than the echo model. And I have a CS330 that I love.

Opihi59

ArboristSite Operative

(fake Mexican accent...) Paint? We don't need no stinking paint!!

This little puppy is going to be a work saw, prolly bouncing around in the back of the truck or Jeep, 4 stroking in the cut at WOT. I'll post up photos and stuff as I put it back together. I'm a bit concerned about those loose lower connecting rod bearings staying in place while I get the ring compressed enough to get it going into the cylinder, and seating the cylinder on a light smear of Dirko without them all popping out all over the place. I might not have enough hands, and I'm not sure my usual glue them in with grease will work. Time will tell.

This little puppy is going to be a work saw, prolly bouncing around in the back of the truck or Jeep, 4 stroking in the cut at WOT. I'll post up photos and stuff as I put it back together. I'm a bit concerned about those loose lower connecting rod bearings staying in place while I get the ring compressed enough to get it going into the cylinder, and seating the cylinder on a light smear of Dirko without them all popping out all over the place. I might not have enough hands, and I'm not sure my usual glue them in with grease will work. Time will tell.

Opihi59

ArboristSite Operative

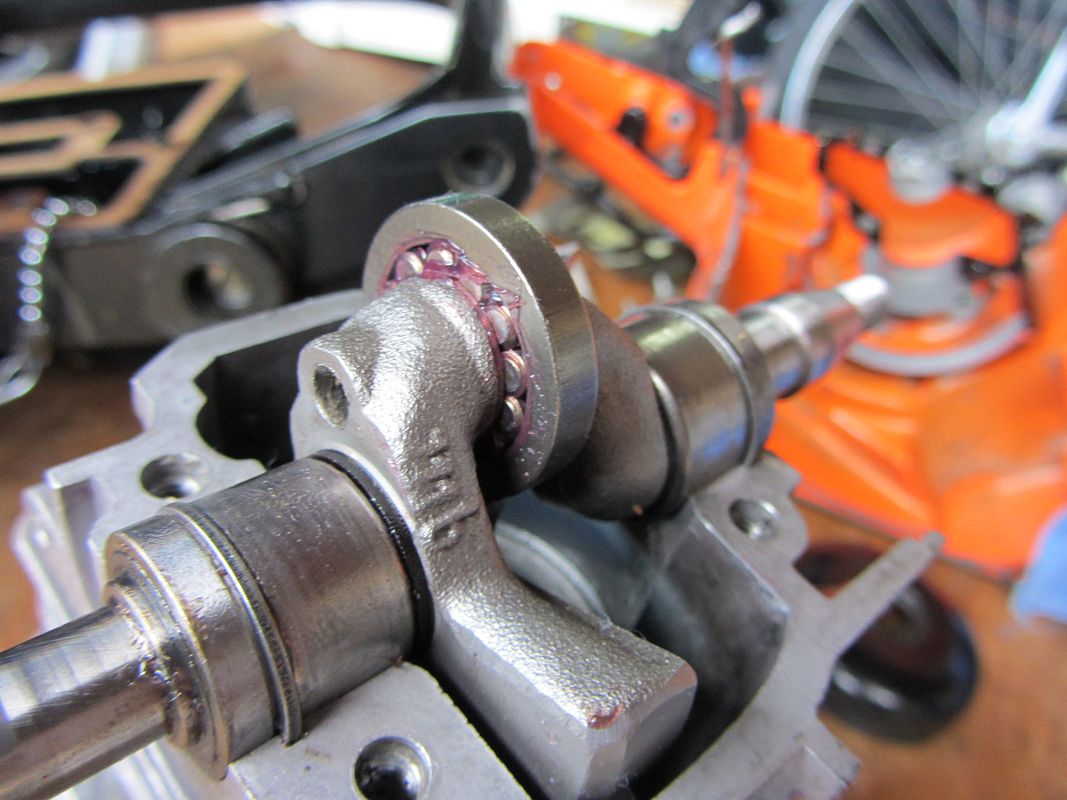

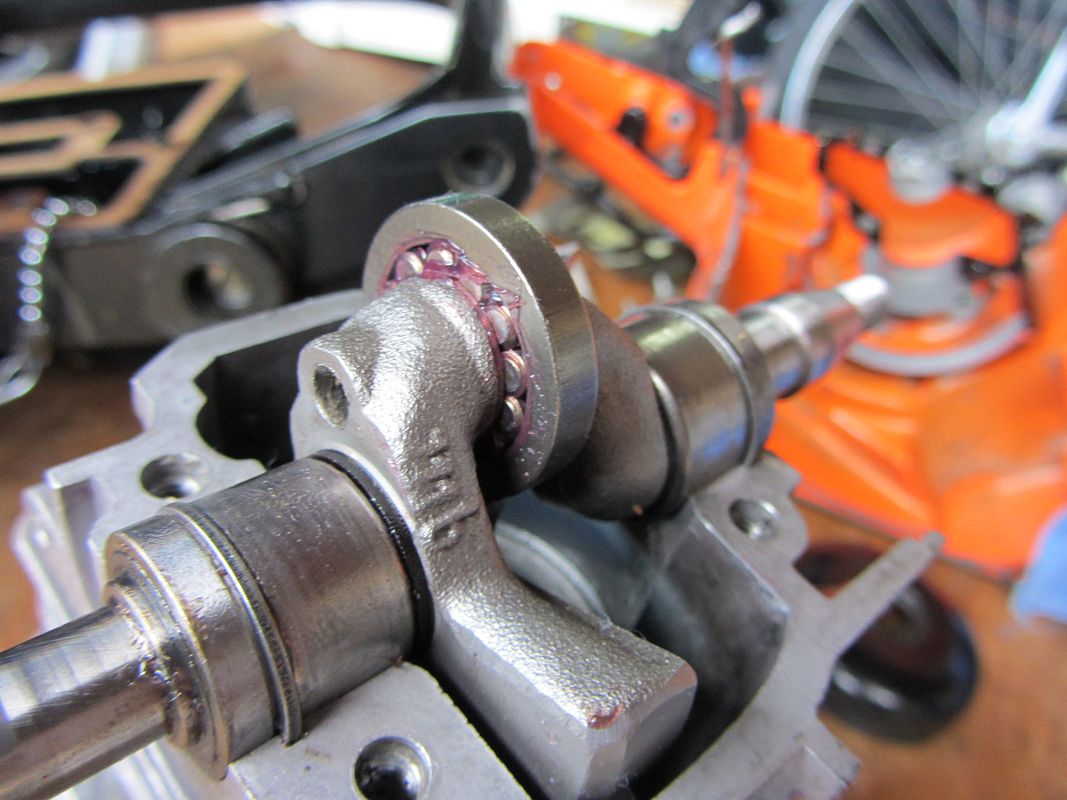

So my piston ring came in the mail a few days ago and I had a little bit of discretionary time to play with it so made a little progress with the saw. I didn't expect so much fun getting those 12 loose bearings on the crank. Despite gumming them in with grease, etc it just was not a fun experience. I don't really know how to advise anyone to do this, it just takes persistence which I do have, and patience which I ran out of fairly quickly. I did this with the piston installed into the bore, wrapped a towel around the connecting rod so that all the bearings wouldn't fall down inside the bore, and just slowly got it all together. Easiest to leave the cylinder/piston sitting in this posture, and lower the case on top of it. I put a thin smear of Aviation sealer on the seam before putting it back together. Crank with bearings back in will look like this with piston installed in the cylinder.

The old (bottom) and the new (top) fuel lines and the old and new (in plastic) filter. Installing the new fuel line worked best pushing it thru from outside the tank rather than trying to push it thru from the inside of the tank. It was easier to seat the grommet the way I did it, from the outside if that makes any sense.

Installed.

So I installed crank/cylinder into the case, closed up the fuel/oil tanks, but take a look at this piece at the end of the screwdriver tip--the case ground. You can't fit that grommet in with the case closed up so I had to take it apart a bit to fit this in and re-close the case. Just make sure that you do it before you put the case together after you wrestle with those crank bearings.

I suppose the last piece I mess with will be doing the rebuild on the carb, for some reason I lack confidence in these. Before I do anything else though can anyone please tell me what the points gap measurement should be set at, and what is the air gap measurement on the flywheel so at least I can call those parts done.

The old (bottom) and the new (top) fuel lines and the old and new (in plastic) filter. Installing the new fuel line worked best pushing it thru from outside the tank rather than trying to push it thru from the inside of the tank. It was easier to seat the grommet the way I did it, from the outside if that makes any sense.

Installed.

So I installed crank/cylinder into the case, closed up the fuel/oil tanks, but take a look at this piece at the end of the screwdriver tip--the case ground. You can't fit that grommet in with the case closed up so I had to take it apart a bit to fit this in and re-close the case. Just make sure that you do it before you put the case together after you wrestle with those crank bearings.

I suppose the last piece I mess with will be doing the rebuild on the carb, for some reason I lack confidence in these. Before I do anything else though can anyone please tell me what the points gap measurement should be set at, and what is the air gap measurement on the flywheel so at least I can call those parts done.

$56.99 ($0.38 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$38.99 ($0.39 / Foot)

$40.99 ($0.41 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

Opihi59

ArboristSite Operative

That would be 0.014" for points gap, and 0.016" for air gap?

Opihi59

ArboristSite Operative

Otay, thanks. Will set at these specs and button it up.

Jim Bozdog

ArboristSite Lurker

Rebuilding a Stihl 015 av Did you buy new oil seals, support washers and needle & cylindrical rollers? Great pics Thanks for taking the time to help us out.

Opihi59

ArboristSite Operative

No, all I bought was ring, fuel line/filter, carb rebuild kit. The crank seals really felt snug, the piston and bore looked really good. I haven't got any further on putting it back together than the flywheel after setting gaps as above, just have not had any discretionary time.

Opihi59

ArboristSite Operative

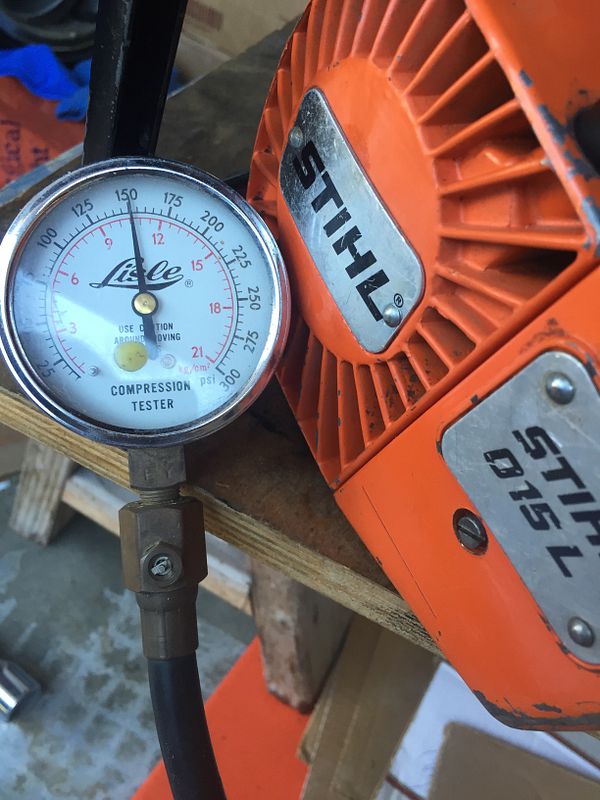

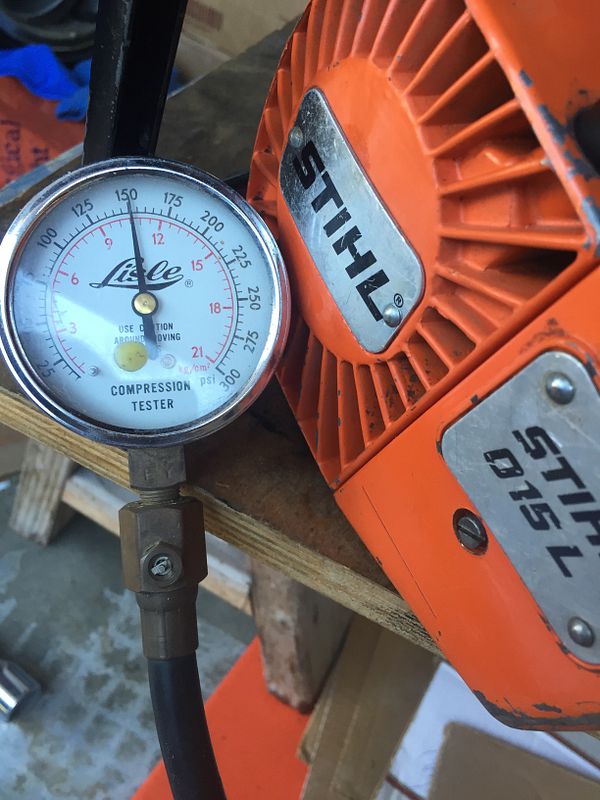

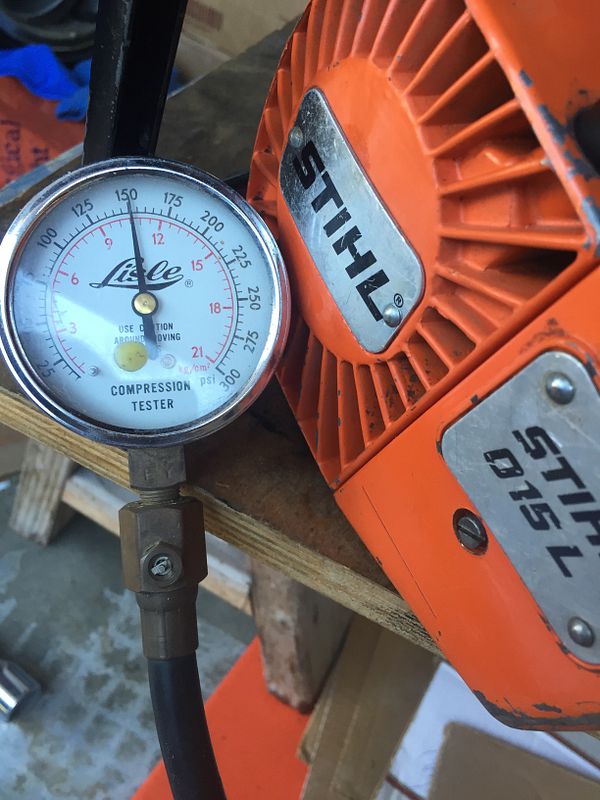

It takes me a while, but I found a bit of time, rebuilt the carb (to me, that means D/G kit, new wire mesh things, new needle valve thing on the pump side), put it back together and tried to run it. It would only pop for a second and that's it, and to keep me humble, it was pouring gas out from somewhere inside the case. Of course, I pulled it all apart to find that it was leaking from the tank around the 4 long case bolts, so either I hadn't torqued them enough, or the gasket had compressed and left them a bit loose after that. I also felt the new fuel line was suspiciously loose on the fitting to the carb, so put a small zip-tie around that. Back together again, and it runs. I have fiddled with the low mix adjusting screw and idle screw and have it where it will idle nicely without engaging the clutch, and it seems to do pretty good at WOT but sounds like there is a bit of a skip to it. Compression is mighty nice. I cut a few coins off of some Kiawe I have cured in the backyard (Haw'n Mesquite) that I split up and use for smoking meat; it cut nicely. I have a bit more work to do to get it dialed in/tuned and of course, I'm a knucklehead when it comes to that, but I am pleased it is running again, and it feels like it will be a nice handy little utility saw for various small jobs. After about an hour of messing with it and cutting/running, I shut it down to give my neighbors a break. This is Hawaii, we seem to be packed in a bit on my island here in the Pacific.

Oh, I need to buy a new air filter, this one is just shot. Put it on while running, and the poor saw chokes off. I blew it out, but it is in bad shape and needs to be replaced, suppose I'll be searching for a new one, or will have to manufacture something that will work, like an old pair of panty hose. Gee, I sure hate to waste my panty hose...........

Oh, I need to buy a new air filter, this one is just shot. Put it on while running, and the poor saw chokes off. I blew it out, but it is in bad shape and needs to be replaced, suppose I'll be searching for a new one, or will have to manufacture something that will work, like an old pair of panty hose. Gee, I sure hate to waste my panty hose...........

Jim Bozdog

ArboristSite Lurker

Nice!

Just FYI if you are in Hawaii I'm sure a room for a week would get you a very nice saw lol !!!!!!!!It takes me a while, but I found a bit of time, rebuilt the carb (to me, that means D/G kit, new wire mesh things, new needle valve thing on the pump side), put it back together and tried to run it. It would only pop for a second and that's it, and to keep me humble, it was pouring gas out from somewhere inside the case. Of course, I pulled it all apart to find that it was leaking from the tank around the 4 long case bolts, so either I hadn't torqued them enough, or the gasket had compressed and left them a bit loose after that. I also felt the new fuel line was suspiciously loose on the fitting to the carb, so put a small zip-tie around that. Back together again, and it runs. I have fiddled with the low mix adjusting screw and idle screw and have it where it will idle nicely without engaging the clutch, and it seems to do pretty good at WOT but sounds like there is a bit of a skip to it. Compression is mighty nice. I cut a few coins off of some Kiawe I have cured in the backyard (Haw'n Mesquite) that I split up and use for smoking meat; it cut nicely. I have a bit more work to do to get it dialed in/tuned and of course, I'm a knucklehead when it comes to that, but I am pleased it is running again, and it feels like it will be a nice handy little utility saw for various small jobs. After about an hour of messing with it and cutting/running, I shut it down to give my neighbors a break. This is Hawaii, we seem to be packed in a bit on my island here in the Pacific.

Oh, I need to buy a new air filter, this one is just shot. Put it on while running, and the poor saw chokes off. I blew it out, but it is in bad shape and needs to be replaced, suppose I'll be searching for a new one, or will have to manufacture something that will work, like an old pair of panty hose. Gee, I sure hate to waste my panty hose...........

Drop the air filter in hot water with dish soap and let it soak. As long as the flocking don't come off your good.

Opihi59

ArboristSite Operative

The flocking is totally flocked off. What The Flock. Gotta find some other filter now. I am guessing I can stuff the existing filter into a panty hose and make it work. The good thing is that at least I am running now with this little saw and slinging chips.

I have discovered it is a bit heavy for a tophandle, maybe I just need to get stronger, but since I blew out my elbow (dominant) maybe I need to learn how to use it lefty. Sux being old. Maybe my boys will take it over and steal it from me like a few other saws. But that's why I build them........

I have discovered it is a bit heavy for a tophandle, maybe I just need to get stronger, but since I blew out my elbow (dominant) maybe I need to learn how to use it lefty. Sux being old. Maybe my boys will take it over and steal it from me like a few other saws. But that's why I build them........

Used a swatch of felt from the wife's sewing supplies on a Pioneer filter. 3M weatherstrip adhesive around the edge.

Microfiber blanket material looks good also.

Microfiber blanket material looks good also.

walterg

ArboristSite Operative

Nice job on the 015. I really enjoyed reading this thread.

My next Stihl project saw is a 015 I bought a year or so ago.

Hopefully I wont have to tear mine all the way down.

Either way I'm looking forward to it.

My next Stihl project saw is a 015 I bought a year or so ago.

Hopefully I wont have to tear mine all the way down.

Either way I'm looking forward to it.

laseradam

ArboristSite Lurker

I have enjoyed reading your post about you 015. I also have one that I am working on and would like to ask you a question that would help me out. I can't get mine to oil the chain. Took apart the oil pump and it is working. Went through a bunch of other things but when I look and probe into where the oil exits above the bar, on the right side of the indentation. their is the beginning of a hole about 1/8 inch in diameter. But it bottoms out about 1/4 inch deep. I am wondering if it was never machined out at the factory. Would you be willing to look at you saw and describe what he oil hole looks like? If it continues straight to the right or if it connect with another channel.

Similar threads

- Replies

- 40

- Views

- 2K

- Replies

- 69

- Views

- 6K