I think its AV time and then call it quits for the day!

Yes it is!Is that a harbor freight heat gun? I just bought on of those!!

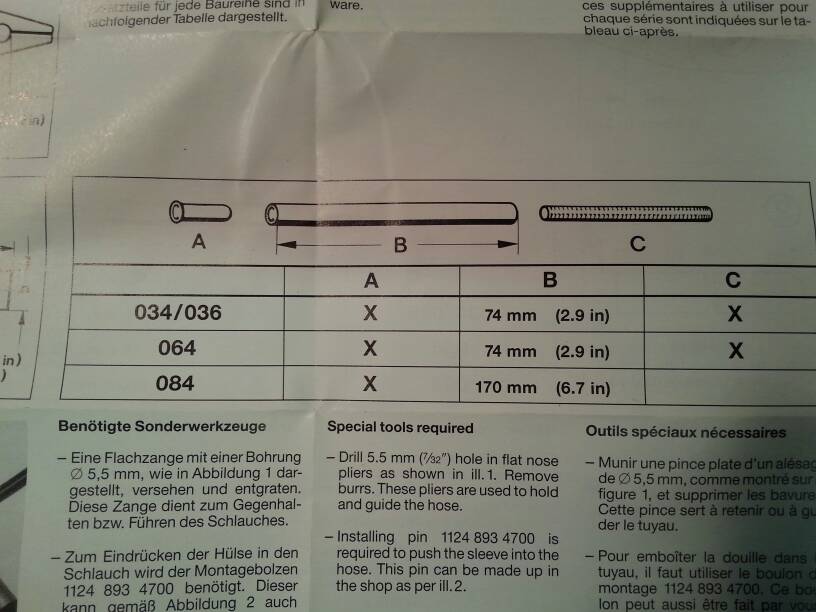

After messing the first one up I started thinking why this was so hard and how can it be made easier. I made a tool to install the rivits in the badge I replaced on my recoil cover. It was an old broken screw driver that I ground to a blunt point. I thought ill see if it fits in the oil line. It was slightly bigger than the ID of the oil line. I thought great! I heated the end of the oil line with a heat gun. I heated the end of the tool a little also. I stuck the tool into the end of the oil line and flared it out a little. Heated it up again and then removed the tool and shoved it down onto the oil pump. Got it down over the second barb! I then measured the 2.9" that the instructions say it should be and cut to length. I then slid the spring in the oil line. Back to the heat just above the barb from the oil pump. Moving fast through the heat while rotating I gently started to make the bend. After a few minutes I was happy with the curve I had. Slid the oil line into the hole and out the oil trough. Heated that end as I did the other. Stuck the tool in to flare a little. Grabbed the brass insert and started it in. Used the blunt point driver to push it in! Done!

Whenever your ready! I dont think you have an oil pump yet do you?Its true a old dog does learn tricks Awesome job. When at that point you can do mine.

Sent from my iPhone using Tapatalk

You guys are making me jealous with your shiny white cases and all. I'll trade ya my 064 when you're done! Haha.Whenever your ready! I dont think you have an oil pump yet do you?

Well you could always send yours over this way and im sure Mike can make yours nice and shiney!You guys are making me jealous with your shiny white cases and all. I'll trade ya my 064 when you're done! Haha.

Very nice work!

Well you could always send yours over this way and im sure Mike can make yours nice and shiney!You guys are making me jealous with your shiny white cases and all. I'll trade ya my 064 when you're done! Haha.

Very nice work!

Enter your email address to join: