treeslayer2003

Addicted to ArboristSite

whats that about a hole in a pair of flat nose pliers?

Ya the instructions say drill a 7/32" hole in a pair of flat nose pliers!whats that about a hole in a pair of flat nose pliers?

Hey thanks im having a blast working on it! Im learning a lot along the way. I know he is! He just better not jump the line with the Monkey!I'm gllad you saw my jest. I can't do the smilies on my phone. I hear you on the long hours. I have had 2 days off in the last 5 weeks. There are times when I'm not even sure what day it is.

Beautiful job on the saw and you better hurry up cus Mikes gonna catch you with his build.

niceWell I said I was going to take my time with this build but I cant stand how slow its going! Sorry... I promise it will speed up by the end of the week! I got the cylinder on today. I used the gasket with a little Motoseal. I have to put the flywheel side seal in tonight and tomorrow ill do my pressure and vac test. A couple parts im waiting for will be in today so hopefully I can get everything together quicker then I have been!

Nice! Powder coat is awesomeWell I said I was going to take my time with this build but I cant stand how slow its going! Sorry... I promise it will speed up by the end of the week! I got the cylinder on today. I used the gasket with a little Motoseal. I have to put the flywheel side seal in tonight and tomorrow ill do my pressure and vac test. A couple parts im waiting for will be in today so hopefully I can get everything together quicker then I have been!

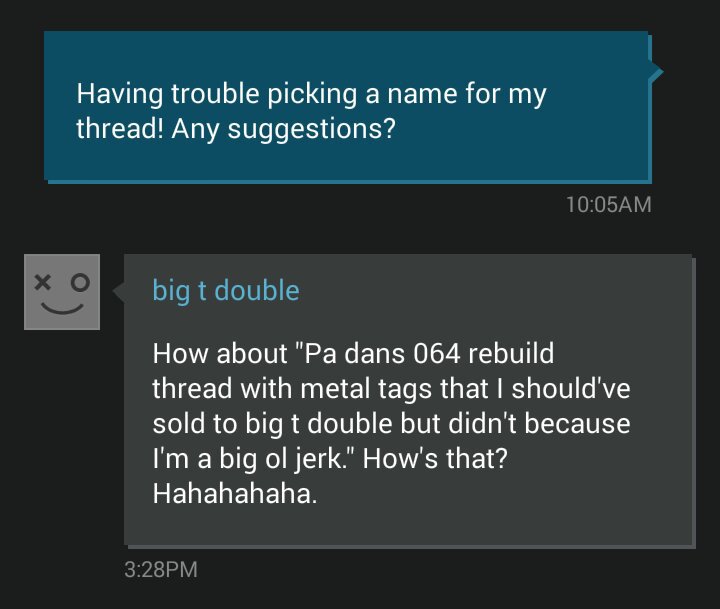

thats a 64 dollar questionWow the hostility! You mean something like this?

Use a sheetrock screw to barely pierce the seal and then pull on the screw with a pair of pliers.Did a vac and pressure test today and it failed!Checked all the seals and saw bubbles on the flywheel side seal. I have another new seal (thanks again Mike) to put in. Im having a little trouble getting the bad one out! Any tips would be appreciated!

small drill bit and a drywall screw and atttach vice grips to head of screw and use end of crankshaft to pry against. Be careful not to scratch crank or crankcase bore. May have to use 2 screws on opposing sides to ease seal out side to side alil at a timeDid a vac and pressure test today and it failed!Checked all the seals and saw bubbles on the flywheel side seal. I have another new seal (thanks again Mike) to put in. Im having a little trouble getting the bad one out! Any tips would be appreciated!

Stihl seal puller with 4 sets of jaws 175$I have searched AS and found those ways but that seal is so small im having a hard time seeing how the screw method will work. I did make a tool with a carb screwdriver but ran out of time and had to go to work. Ill try again when I get home tonight.

Enter your email address to join: