rodeobob

ArboristSite Operative

Motor looks a bit Villiers on that saw.

Motor looks a bit Villiers on that saw.

I cut down a palm tree for a neighbour and chunked it up into little pieces.

I did it all wrong two vertical bore cuts, not sure what I was thinking...............

so changed my mind a little and I did a Humboldt face cut below them and a back cut above them and wedged it over.

No letter box was hurt.

ten minutes latter I was being paid in cold beverages on the back deck

I cut down a palm tree for a neighbour and chunked it up into little pieces.

I did it all wrong two vertical bore cuts, not sure what I was thinking...............

so changed my mind a little and I did a Humboldt face cut below them and a back cut above them and wedged it over.

No letter box was hurt.

ten minutes latter I was being paid in cold beverages on the back deck

we cut out Burrawangs on the farm & hazard reduction work in the rfs ...man those things are seriously corrosive, leave a saw uncleaned for a week, and there's holes been chewed right threw the clutch cover. ...I hope you washed your saw David before the palm sap chews the case out. Cheap plastic saws are the best ones for palms

Widowmaker 1,,,

i like that 3120 set up for a rail in your sig pic.

Does that little pipe vibrate, i cam picture the 4 screws holding the plate flogging out over time or have you welded that up to the muffler.

Talking about felling palm trees, I saw this interesting technique a while ago...

Youtube "Tongue and Groove Tree Felling Technique"

Can't post the video because of advertising issues.

lol, stihl fanboy in the fleshEDIT: Yep, it was a video posted by you know who

lol, stihl fanboy in the flesh

Was that from everybody's favourite palm guru in Queensland? I think I know the video and it is a very handy technique on smaller trees where you struggle for wedge room. It's a documented technique that's useful on all species.

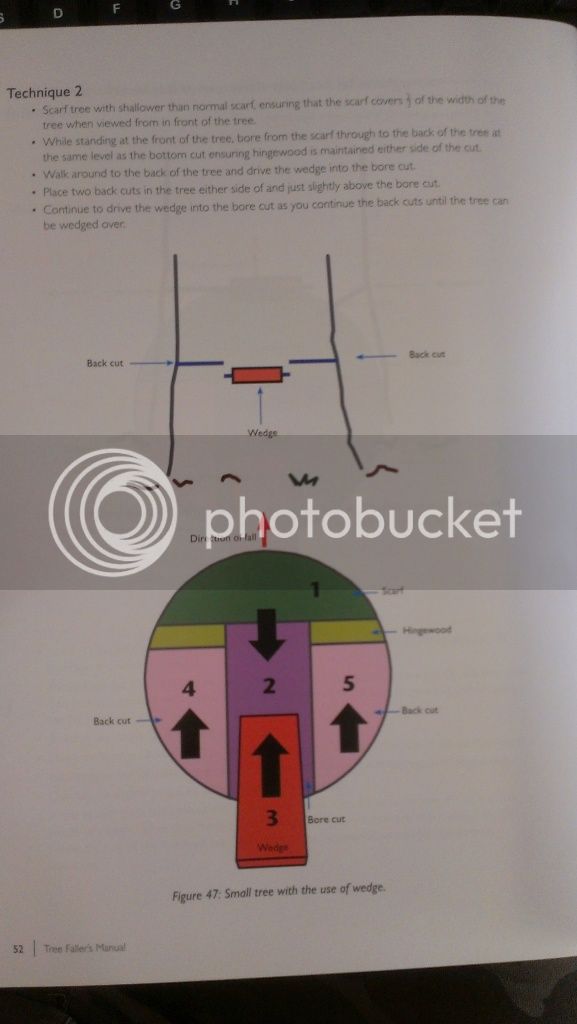

If it's the one I'm thinking of you cut your face, bore through from front to rear level with your bottom flat cut (on a standard scarf, not a humbolt), hammer your wedge in from the back through your bore cut, then run two back cuts just above your wedge without actually cutting above your wedge to avoid pinching the bar tip. When you finish hammering in your wedge it shears through the remaining fibres and bingo

I've never taken photos after doing it myself but this is a messy example of the finished product from a tree I saw at the Tahune Tree Walk in Tasmania a few years ago. One of the local guys must have used it on a smaller tree that was hanging over a path...

EDIT: Yep, it was a video posted by you know who and I don't think that "Tongue and Groove" is the actual technical term. Can't find my felling manuals to confirm the name dammit

If i may inject a little from a industry (timber) point of view.

This practice is common in our job, i have done it thousands of times.

Safety officers and falling trainers will not allow the practice until the faller has the necessary skills to correctly assess when and when not to perform this practice. We do it a lot arround filter strips ect on millable logs of all sizes. It is also done as a last resort to fall a tree to make extraction easier for skidders, dozers ect. (that is a very important skill in itself)

The faller must also hold a currant open fallers licence, which proves his falling experience and also proves his ability to read standing timber across all types of falling for correct felling procedures.

To my knowledge this practice is not in any felling manual due to its dangerouse nature, it is however excepted in the right aplication by fallers trained to a higher standard than ordinary log fallers.

I can't beleive however anyone would show pics like that publicly, its a dangerouse practice if not done right and the results can be perminant.

Not sure if you're talking about the same cut Neil. This was taught in the basic felling course by LITA and I've seen it in a few manuals including a reasonably current NSW Forestry manual if I remember correctly. To the best of my knowledge it is generally only recommended on smaller trees where a standard wedge won't fit behind the bar. I've never seen this technique used on trees larger than about 12" but you are correct in saying you need to know what you're doing just like felling anything with a chainsaw.

I'd be interested to know why you would use this technique on larger trees as I'd have thought other cuts would be more suitable?

Sorry about posting a pic of it but at least I didn't post a video of it like old palm tree mate did.

No dramas matt, i just thought it odd. I must apologise for running off with the keyboard until thinking more on the context of rudy's post.

A common example of this is falling spars on the edge of a filter strip or riperian buffer to meet up with a snig track or suitable place to land it. You are so right is saying there are easier ways of falling around gulleys but at times it cannot be done unless this practice is performed.

If done right, (useing the abc method)this practice is not hard in larger spar size trees, and is best affected where a tree has a heavier lean towards a gully and needs to be pulled straight back away from the filter strip. The general practice of inserting the wedge behind the bar is the obviouse choice for sure.

note to self,,,

although trained in all facits of hardwood harvesting, i am not trained in domestic arbourist, treelopping or any type of tree removal in towns anywhere and will leave that to those specalists in that field.

you got me thinking Neil, thats dangerous for the wallet mate.. .might use these instead of them stock screws, before welding ....im shore they'll hold up? what say you bro ?

nylon lockers might melt, but ill use some high temp locktite

The problem with bolts, if the nut comes off the bolt it may get sucked into the piston before being spat out through that pipe. At least with screws they just come loose and fall out.

Enter your email address to join: