Terry Syd

Addicted to ArboristSite

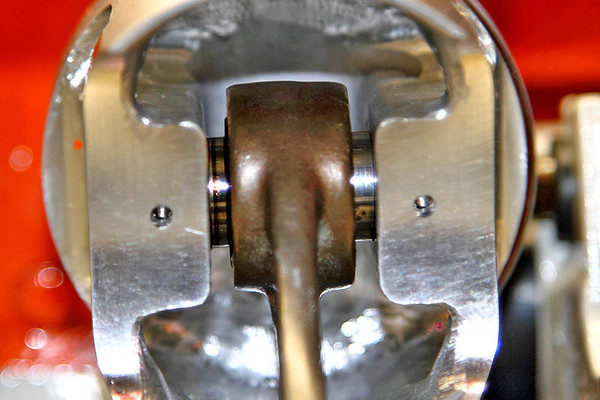

Pop-up

I'd expect that a lot of people would discount the wristpin gap issue if the piston came with a pop-up. With the pop-up, they would probably be willing to make some compromises (such as a longer bearing) in order to have a high compression piston.

Is there any feedback on why there isn't a pop-up/high compression piston?

I'd expect that a lot of people would discount the wristpin gap issue if the piston came with a pop-up. With the pop-up, they would probably be willing to make some compromises (such as a longer bearing) in order to have a high compression piston.

Is there any feedback on why there isn't a pop-up/high compression piston?