2000ssm6

Stihl User

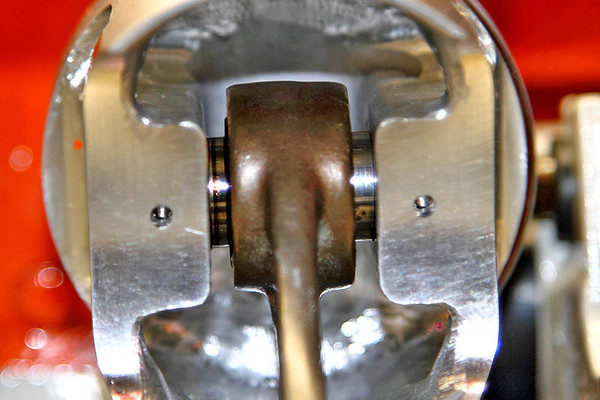

All pistons float on the wrist pin, just not normally this much. The crank centers the rod between the pin bosses.

That was what I was looking for.

All pistons float on the wrist pin, just not normally this much. The crank centers the rod between the pin bosses.

Good point but Homelite nor Mac make saws worth a crap "anymore". I know they were great saws for their time era. Maybe it worked for them but why doesn't Stihl, Dolmar or husqvarna use these methods today? I just don't see any advantages.....

Who would spend $130-140 on a piston then have to get spacers machined? Even with spacers, will these pistons go 1000-2000 hours with all that flop? Sounds retarded to me but I'll stick with Stihl and Mahle.

Maybe they don't anymore.

But back in there day those

old mac's and Homelites survived

the most demanding conditions and

threw more chips than most.

And that little thrust washer didn't stop them.

Lee

That was what I was looking for.

First of all, I'm not real happy about this either. But the engineers say it's OK. I'm going to run it initially with the OEM bearing. I do intend to buy the wider B1015 bearing though. That'll give me a chance to go back in there after running it with the OEM bearing.

Do remeber that the rod will never be off to the side like I posted. It will be centered as in the pic below.

Brad, the wrist pin bearing offset will be fine in actual use. There is plenty of support left between the parts, the piston will not tilt off center on the pin, plenty of lubrication will make it to the needles, etc.

I would run it, like I stated snowmobile engines have far more play as they rock around on the wristpin. I even think that this may allow more oil to enter the bearing? I remember a post from Lakeside about high rpm and spacers in saws and that it led to failures.

The wrist pin being able to move off center isn't going to hurt anything, the rod will stay well centered with plenty of contact area with needle bearings in actual use.

I still don't get a "warm and fuzzy" putting things together that could be better. I'd opt for a longer bearing with less movement anyhow, last resort would be to fabricate/obtains some small/hardened spacers to keep the bearing centered better.

I don't think the space between the rod and the piston will matter, I see this in snowmobile engines all the time,once located inside the cylinder it ain't going anywhere!

I understand that,but like I said snowmobile pistons are the same way they slide back and forth on the wristpin quite a bit,and the wristpin bearing sliding out the side is a non issue.

Baileys/Wiseco said:"We discussed the bearing float vs. wrist pin tower distance prior to production. Our lead engineer questioned this early on and we gave him the feed back of being a "Bottom Guided" crank assembly. When the parts are assembled in the engine the crank keeps the rod in center of the towers, but you will still have a small portion of the bearing that will be exposed. This is acceptable, just not as extreme as the "bench test" picture that was posted on that link suggests. The crank centers the rod to the piston, the pistons remains center in the bore, but yes.. the bearing will slide side to side and have minimal exposure which is acceptable."

run it as intended and blame wiseco if you must but im thinking they should know more than us right?I really appreciate you guys experience and advice. Lot's of people can offer advise based on opinion or gut feeling. But it's a different story when it comes from real world experience.

With that said, I'd like to dig a little deeper into this. Have you seen sled engines where the bearing actually comes partially out of the rod? I understand that the bearing floating left and right is a non issue. I understand that the rod stays centered between the pin bosses. Do the sled engines use spacers to limit bearing travel?

As indicated by Wiseco engineers, it's said not to be an issue. But I still plan to go back in a a later date to inspect after some run time, and install the wider bearing just for peace of mind. That'll probably also help if/when I decide to sell this saw.

With that said, I'd like to dig a little deeper into this. Have you seen sled engines where the bearing actually comes partially out of the rod? I understand that the bearing floating left and right is a non issue. I understand that the rod stays centered between the pin bosses. Do the sled engines use spacers to limit bearing travel?

I have worked on and rebuilt many Ski Doo snowmobile engines in my time. Many of there models like there triple

cylinder 600, 700, and 800cc motors have a cage less bearing with spacers on each side of the rod to keep the needles from coming out to far.

Lee

Lee, what material is used to make those spacers ?I have worked on and rebuilt many Ski Doo snowmobile engines in my time. Many of there models like there triple

cylinder 600, 700, and 800cc motors have a cage less bearing with spacers on each side of the rod to keep the needles from coming out to far.

call or email them and see what the heck is the reasoning for this.Here's the low down on the 440 piston. Distance between the pins is fine, but they're 2mm off center. My measurements show a 1mm difference between pins, but that's a stong 39mm. I can't measure much closer than that with what I have. So it's probably within .5mm. Reguardless, that's not a problem at all. The distance between pin bosses is within .006". Notice the wider skirt width on the Wiseco

call or email them and see what the heck is the reasoning for this.

With that said, I'd like to dig a little deeper into this. Have you seen sled engines where the bearing actually comes partially out of the rod? I understand that the bearing floating left and right is a non issue. I understand that the rod stays centered between the pin bosses. Do the sled engines use spacers to limit bearing travel?

I have worked on and rebuilt many Ski Doo snowmobile engines in my time. Many of there models like there triple

cylinder 600, 700, and 800cc motors have a cage less bearing with spacers on each side of the rod to keep the needles from coming out to far.

Lee

yes some are cage less with spacers but remember these engines turn 8200 rpm only!

I just rebuilt a 583 rotax that slid back and forth much like we are discussing but when I tore it down it did not even seem like the bearing ever left the rod end, as there were no marks on the inside of the bosses at all.

I wonder how much the piston bosses will expand once heated? I'm not saying they will fill in the gap by any means, just wondering out loud.

Brad, I see the Wiseco skirt is wider on the 440, is it any wider on the 660?