I would heat PTO side of case with heat gun and drive bearing out with a socket and hammer. Maybe this is the most diabolical, evil, horrible way to do it but it's worked for me in the past. Or put it in the oven on a cookie sheet at 250 degrees and wait til you hear the bearing fall out. That's worked for me too on many many motorcycle cases.

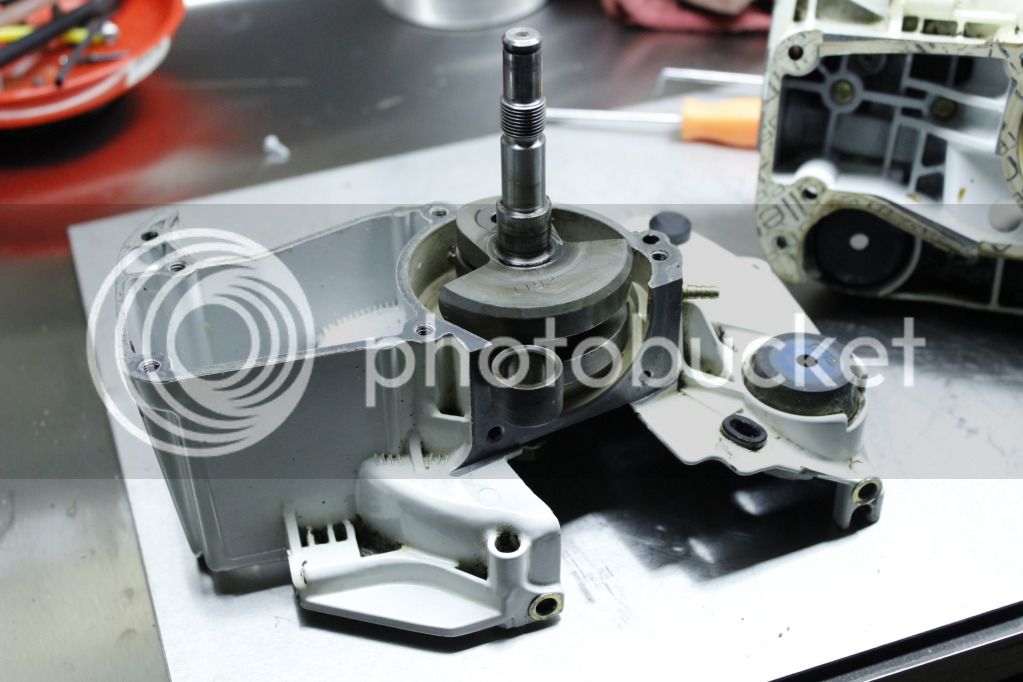

On the flywheel side, and others may chime about my ineptitude, I thread a clutch center section on the crank, put a socket on the hex drive on the clutch center part, and hit socket with a hammer while supporting the case. Make sure the clutch center is at least snug on the crank threads so it doesn't back off and hurt the threads on the crank. Heating the case works well on this side too. To support the case, I lay a couple rags on the bench and use that to hold up that end while holding the other end in my hand. Then bearing splitter to get bearing off crank.

Don't get yourself spun out. I've worried many times about weather or not I'm going to damage a case. I take my time and be as careful as I can and haven't messed one up yet. :biggrinbounce2: