I got everything preped for assembly. Bearings oiled, rings clocked, seals greased, sealing surfaces cleaned and so on. I usaually rough up the crankcase flanges lightly with 400 wet/dry paper to have a very clean surface and give something for the motoseal to stick to. Then I wipe all sealed surfaces down with denatured alcohol to remove any oil or grease. Assemble the two halves and torque the large bolts in the oil tank to 60 in-lbs and hand tighten the small outer bolts with a 1/4" nutdriver. Dont forget to put sealer on the heads of the large bolts inside the tank so you dont fill the crankcase with bar oil

What brand of torque wrench is that on your table? Any recommendations on one for in-lbs use?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

McCulloch Chain Saws

- Thread starter Bruce Hopf

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It is an ATD. Its is hard to find an in-lbs torque wrench at the store. usaually you have to order them online or go to a speciality store. don't buy one from harbor freight or the like. no point to a torque wrench if you cant verifiy the quality/accuracy.

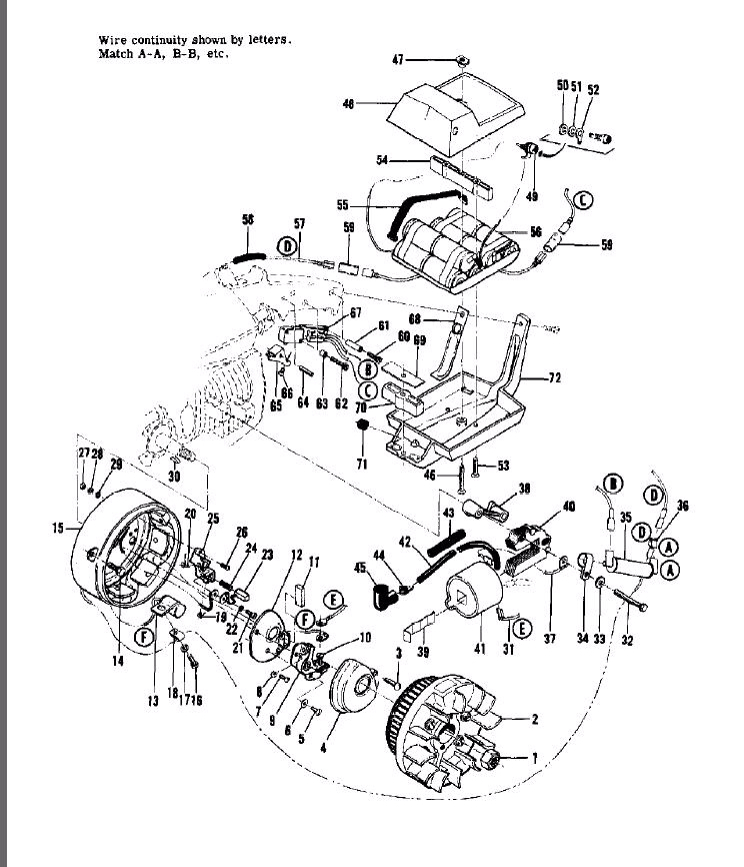

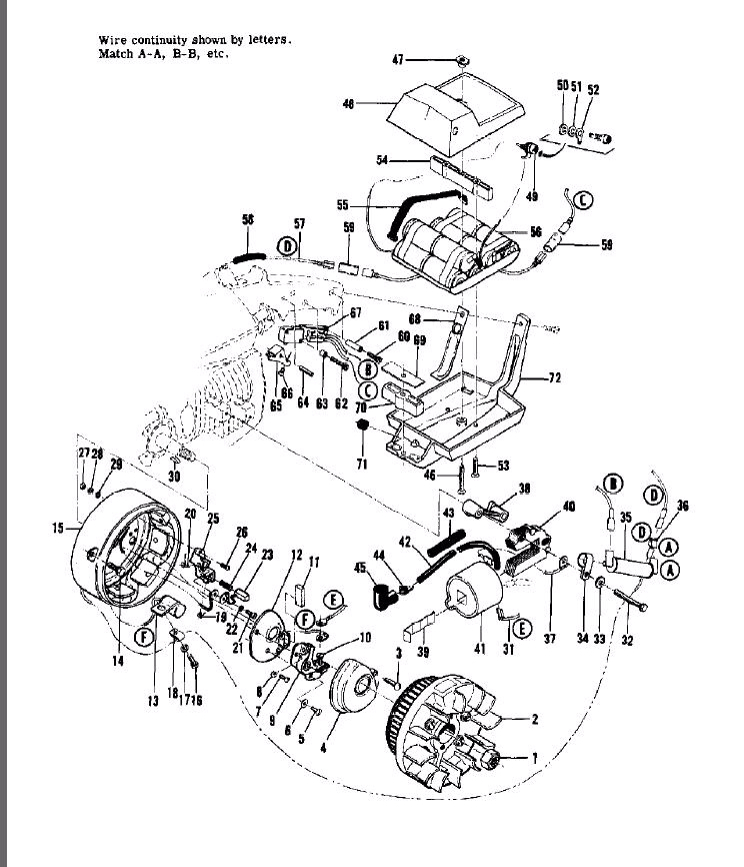

Does any body understand the starter/generator wireing diagram for the electric start 10 series? I hooked everything up the way it came apart and nothing happens when I throw the switch. the wiring diagram shows no ground connection and no power supply to the motor. I need some help from an expert! the pictures in all my manuals are very grainy and I cant tell in detail where the wires go.

Appreciate the info on torque wrench. It has been a couple years back, but tried to get one at local NAPA and didn't have any luck. Memory is bad sometimes and they may have found something in their catalog and I just got price shock.

joeymt33

I bleed YELLOW!

Hope these help Steve.

joeymt33

I bleed YELLOW!

I didn't take many pics when assembling mine. I did have to replace or add a wire. It's the brown on in the pics.

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$59.99 ($0.40 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$39.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$21.99 ($3.66 / Count)

Firewood Log Splitter 45mm+32mm + 4 Handles (Square + Round + Hex Shank + Small Hex) Wood Log Splitter Easy Splitter Detachable Drill Bit Heavy Duty Electric Drills Screw Cone Driver Removable

JianShiMoQinDianZiShangWuYouXianGongSi

$14.99

$17.99

Fiskars Pole Saw Blade Replacement for Fiskars Pruning Saws and Tree Pruners, 15" Blade with Woodzig Chainsaw-Style Tooth Design

AMZ South Supply

$56.99 ($0.38 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

$56.99 ($0.38 / Foot)

$59.99 ($0.40 / Foot)

Double Braid Arborist Rope Orange(1/2 in x 150 ft) Arborist Rigging Polyester Rope - 48 Strand Rope Swing for Tree Bull Rope for Outdoor, Climbing, Swing, Sailing

Cosirulnta Shop

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

ethar

ArboristSite Operative

If anyone needs it I have the full service manual for the 10 series with a good wiring diagram

If anyone needs it I have the full service manual for the 10 series with a good wiring diagram

I could sure use one for my PM700 and SP80

Thanks

joeymt33

I bleed YELLOW!

I could sure use one for my PM700 and SP80

Thanks

PM me

Ok guys you have all been very helpfull. Joey, Your pictures make lots of sense, Thanks as always but here are the diagrams out of the manual. the top one is where it shows to short the battery to the resistor and doesn't clearly show a body ground. the second pic is what I think it should be wired with the resistor in series with the battery and the generator

ethar

ArboristSite Operative

That would make sense to do it like that is there a place for a bolt in that area for a ground. From joey's pic there seems to be a plate on the coil that uses the coil grounding as the chassis ground. It looks like a wire from the battery pack a jumper wire from the ground and another jumper wire from the resistor all attach at this point. From my electrical experience the circles on here should represent jumper (attachment) points.

OldDeadWood

ArboristSite Operative

joeymt33

I bleed YELLOW!

Sweet! You've almost got it

Outstanding!

ethar

ArboristSite Operative

Wiring is always a pain. Least you got it going.

what pogo said... never seen a push button saw before

Similar threads

Latest posts

-

-

Scrounging Firewood (and other stuff)

- Latest: Stihl_Fanatic

-

-

Vintage Saws - One Man Crosscut saw vs Bow/Frame saw?

- Latest: James Sawyer

-

-

-

-