Hi Folks,

It's been a while since I've posted I finally got the carb kit for my 1-42 and went through it last night. Apart it comes.Put it back together this morning. Found a big fat blue spark but couldn't seem to get it to pop even with fuel in the carb and through the exhaust port. Anyway not sure what I was doing wrong but finally fired and away it went. It wouldn't keep running though. I think it was flooding out and there is excess fuel coming back into the carb box. By the way I took it's PSI and found only about 105PSI. The piston looks a little scored, I think more from carbon than being too lean. Cylinder looks good. I seem to be getting intermittent spark as if the plug cap is not 100% making good contact sometimes.

Although I could not replace the inlet seat and gasket because I couldn't remove the old one. Don't have a 5/16 socket with thin enough walls. I just went back to the bench to find fuel leaking all over. So I'm guessing the inlet seat and the new needle aren't meshing well..

The fuel line to the tank has yellow paint on it so I assume it's original but seems sound. The one in the tank is black and also seems good but has no filter upon closer examination

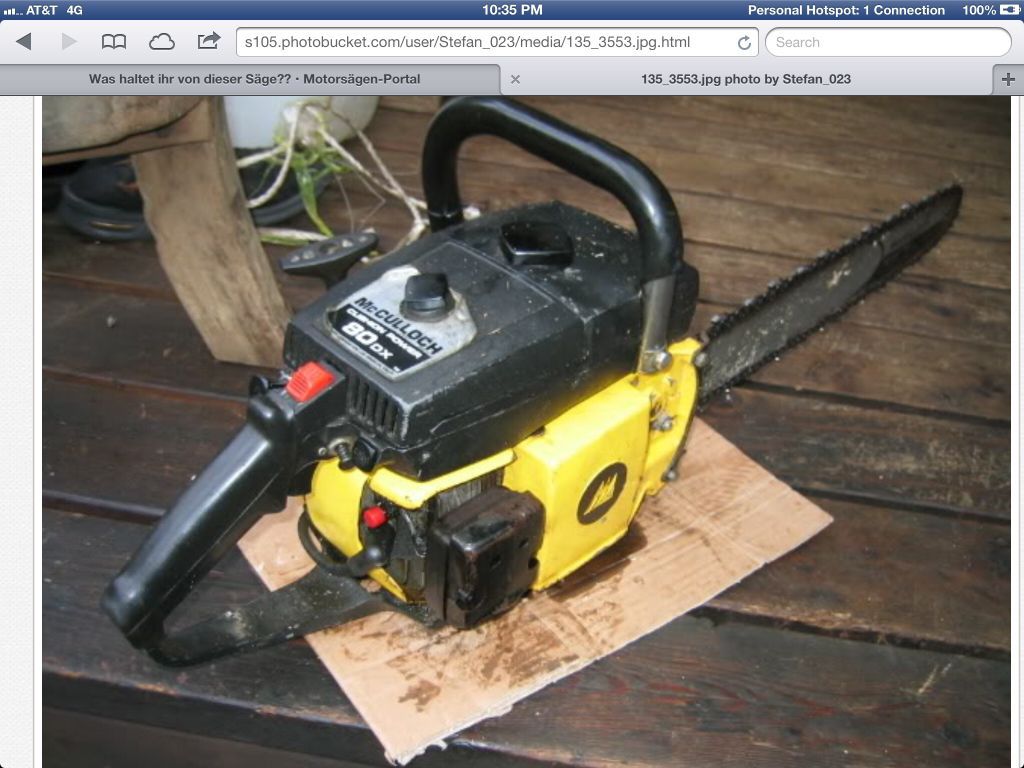

Sounds great through that new stack muffler Mark, thanks for that. I'm hoping to use this as a replacement for my Dad's 380 that I gave away on Ebay before CAD struck. This one seems a bit lighter than he 380. It has a 16" hard nose bar with a.404 chain.

A work in progress!

Lee

OK so I don't have a bench grinder I decided to go back to the old needle and lever as they didn't leak fuel before and the saw ran. Got it all back together and couldn't even get it to pop. I'm thinking that with only 105psi it may not be enough comp to run. It certainly pulls over a lot more easily than a 380 that I once had.

So where is the best place to get rings? And would you recommend Caber?

Thanks.

Lee