watsonr

Addicted to ArboristSite

- Joined

- Jan 3, 2010

- Messages

- 7,088

- Reaction score

- 2,132

IPL calls for 7/8 on the low and 1 1/8 on the high.

Automatic transmission fluid sometimes works to free up stuck pistons.

thanks for the info guys i can get it to pop and run for a few seconds then dies, i have to do some adjusting on the decomp it does not operate very well and i have trouble getting it closed with it running. it does not pull over very good with it shut, and i feel like something is going to brake when it catches(either me or the saw something has to give)IPL calls for 7/8 on the low and 1 1/8 on the high.

As promised a couple of days ago, photo's from my saw starting excecise on Saturday.

First two are the 55 and 1-72, both equipped with Tilloston carburetors and both started within 6 or 8 pulls even after setting for 4 months or more.

After that I just went ahead and started all of them, here there are spread out for your enjoyment. Front row L-R: SP125, 7-10, 10-10S x 2, SP60 just behind (darker yellow), SP85 beside the SP60, CP55, SP118, SP125, SP105, SP105, 1-76, 1-85, 1-72, 55.

I don't know why this one was so shaky, maybe that was fatigue after moving all these saws around and starting each one: L-R Jonsered 621 x2, 930, 910, 2.3 AV Homelite behind, 036, 066, PM100, 840 with the broke fuel line.

Now a few small saws starting at the bottom: Olympyk 935, SP40, MM 110, JD??, Titan 57 on top. Way in the back next to the bag of charcoal is the 77, and hiding behind the bi-tricycle is the Super 797 with the black and yellow McCulloch bar.

Finally, a close up of the broke fuel line, guess I know now why it would not run.

Mark

I got the CP70 cleaned up ready to dismantle. I hate tearing down dirty saws.

Are bearings and seals available for this saw? Or should I take them to a bearing shop and see if they could match them?

Cool deal on the machining!Well Mac fans, I have dropped off the cylinder and piston at the machine shop earlier today...

Should be done in a week or two... I specified for .004" of clearance between the piston and cylinder... after I give it quick and good hone, I imagine it'll be around .0045" or so.===

Gotta pick up a bigger c-clamp to use with the support block

=== use with my homemade soda blaster===

Cool deal on the machining!

c-clamp? not sure of what you're facing in terms of space restrictions, but I've had good luck with the 1T version of this: 1 Ton Arbor Press - Harbor Freight Tools 1/2 Ton Arbor Press pressed the wrist pins out of 4 dolmars, plus multiple bearings, shafts, pins in & out of just as many. just watch the max height to make sure it is enough.... for $30 - $45, hard to beat.

DIY soda blaster?... build-to drawings or it didn't happen!

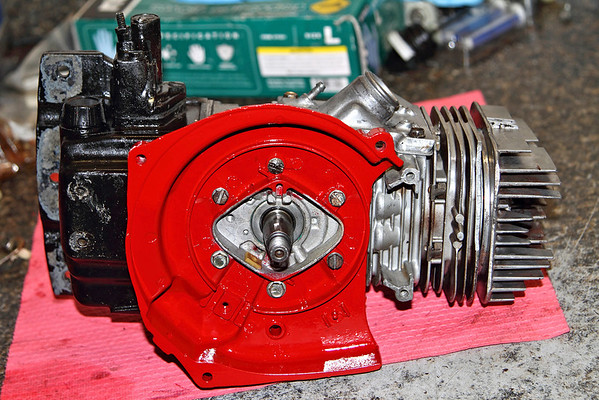

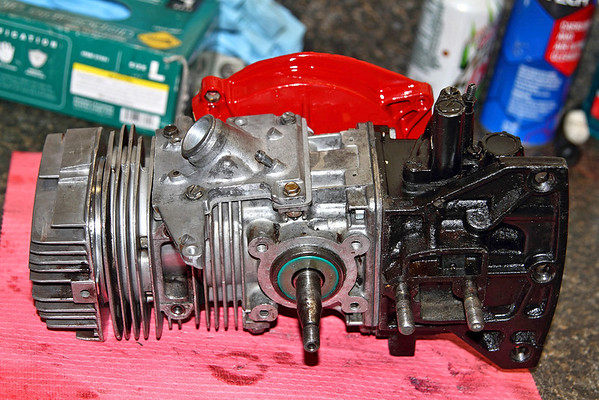

PTJeep, assuming it's a kart block, my best educated guess would be an MC-49.

Top of my head the 49s were 80cc fixed head and not very aggressive. Mac marketed them as a youth/starter class crate-motor.

Sending the 797 block to get bored and ported increasing the bore 0.20 over. New over sized piston and rings, new seals and bearings will be installed. This saw will be restored/painted..but no way will it set on a shelf this saw will mount on the quad with me when I go cutting in the forest for big Ponderosa's. Thanks Lee for great tips on the piston apps and info