Alright ostrich, I think this will fix it...

Here are the pics of the block off/flow redirecting plate I made...

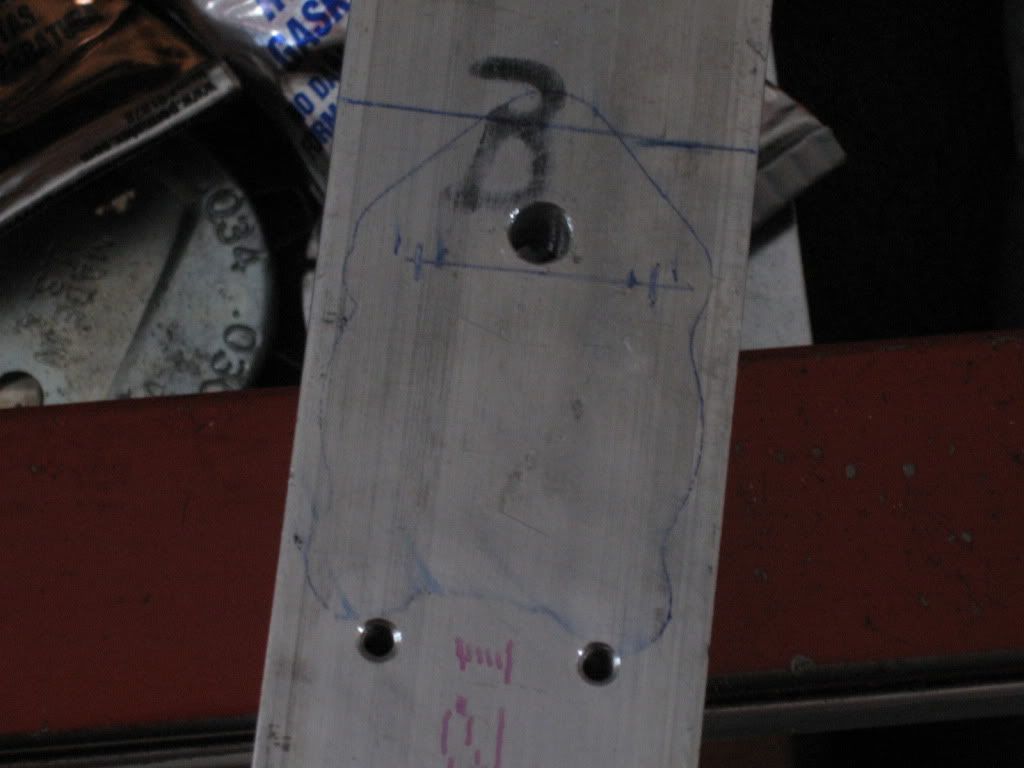

This is the starting point... a rough sketch...

Then we got this... the mounting hole is drilled, and the spots for the oil entry/discharge holes were found...

And the channel is cut to connect the two holes... sorry, this one is a tad blurry...

Then I made the top cover, and a gasket for said cover... the gasket has the channel cut into it as well.

And here I used some RTV to make the o-rings stay put... this is curing as we speak...

And an inside view...

Notice the relief cuts on the bottom right corner of the plate... that's to clear the boss that the oil tank cover screw goes into...

I also had to find a slightly longer screw that would actually work... the original screw is about 3/8" too short and will not even grab the mounting threads in the oil tank...

Took me from about 11 to 5 to get this little plate done. Made me wish I had a Bridgeport and a vertical band saw... I used files, the Dremel, my benchtop drill press, and a couple other tools to get this done... and lots of elbow grease.

I'm think I'm gonna go get me some supper... then check on the rtv and if it's cured, I'll slap it all together and test the oiler on the bench... If it passes the bench test, then I'll put her all back together, fill her up, and make some cuts. Worst case is we find out that the o-ring that is supposed to seal off the crankcase from is not working... white smoke in copious quantities will show if that occurs...