CGC4200

Addicted to ArboristSite

not familiar with 3700

Do they have a primer/air purge?

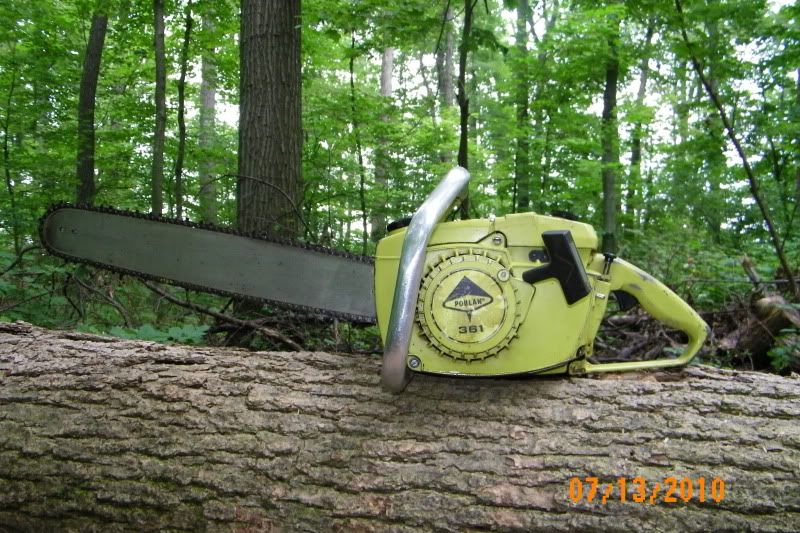

The older Poulans have only one pickup line to carburetor.

Some of the newer ones with air purge have to be just right on fuel

line routing, work great if working right and start quicker, but more

complicated to fix.

Do they have a primer/air purge?

The older Poulans have only one pickup line to carburetor.

Some of the newer ones with air purge have to be just right on fuel

line routing, work great if working right and start quicker, but more

complicated to fix.