An alternator produces AC currant.Generator -DC currant.If DC is needed and an Alt.is in use,send the AC through rectifier and DC comes out.If AC is needed and a generator is in use,send it through an inverter and AC comes out.Pretty simple really.That's false.

An alternator produces electricity by spinning a magnetic field inside a stator winding.

A generator produces electricity by spinning an armature winding inside a magnetic field.

Alternators produce electricity on demand (they can put the driving engine off-load).

Generators produce electricity continuously (the driving engine is always on-load).

Generators need to be polarized... alternators do not.

Alternators are capable of higher output than generators.

And there's more...

*

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Running engines at half throttle??

- Thread starter blkcloud

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

NSMaple1

Addicted to ArboristSite

Unless it's an inverter generator, it's running at approximately 3600 RPMs all the time.

The governor opens and closes the throttle plate to maintain RPMs according to load... it may be "throttling back" under lighter load, but it's still running at maximum RPMs. The higher the load, the more fuel required to carry it... if there's no load the throttle barely opens past idle to maintain 3600 RPMs. That's why I asked @Sawyer Rob if he'd put a tachometer on his engine when he believes it's running at ½ throttle or less... a throttle plate half open on an off-load engine will cause the engine to over rev. Throttle plate position is relative to engine load, not so much engine RPM.

Not an exact comparison... but if you're driving your truck down hill (off-load) at 60 MPH you barely press on the throttle peddle compared to driving up hill (on-load) at 60 MPH. If the hill is steep enough you need no throttle to maintain 60 MPH on the way down (might even need brakes), and going up hill may require you to floor it (and you may still lose speed). On a small engine the governor takes care of the throttle position for you... kind'a like setting the cruise control.

*

Mine is an inverter. It does not run max RPMs all the time. Introduce a small load, it runs half speed. Increase load, it ramps up to max speed. Take some load off, it throttles back to half speed again. Has a switch on it, for Eco Mode. Switch that off & it runs max speed all the time. Switch it on, it reduces speed with reduction in load.

And on the un-exact truck comparison - your truck speed might maintain with the barely pressed throttle going down a hill, but the engine speed doesn't. It drops. My auto doesn't anyway.

sledge&wedge

ArboristSite Operative

Yesterday I ran my Fiskars at WOT for a few hours but then the governor came out and told me it was time to throttle back and help her off-load the groceries from the car. Then I splashed a few 12oz. cans of high-efficiency coolant around and let off a few emissions. Then I throttled back up to WFO so I could get my damn wood split and stop arguing about 4-stroke engines and enjoy my afternoon.

I have no idea where you get such a silly notion... both alternators and generators produce alternating current... unless you add some form of rectification.An alternator produces AC currant.Generator -DC currant.If DC is needed and an Alt.is in use,send the AC through rectifier and DC comes out.If AC is needed and a generator is in use,send it through an inverter and AC comes out.Pretty simple really.

An alternator is not called an alternator because it produces alternating current... an alternator is called an alternator because it alternates its on/off status according to demand... something a generator cannot do.

A generator was originally called a dynamo... but its full technical name is "Alternating Current Generator".

An "alternator" is also an "Alternating Current Generator" that is also capable of automatically "alternating" its on/off status according to demand.

There are what's called D/C generators, but really, they're just A/C generators with rectifiers (just as automotive alternators use rectifiers to become D/C alternators)... remove the rectifiers and a D/C generator becomes an A/C generator (just as automotive alternators would become A/C alternators).

Before the common availability of rectifier diodes, multiple windings and commutator slip rings were used for rectification when D/C was preferable.

(Commutator slip rings can't work with an alternator because the winding is in the stator, not the armature.)

Both generators and alternators produce alternating current... and both can be rectified into direct current.

Both have advantages and disadvantages... depending on purpose. Alternators are capable of producing (on demand) higher output than generators... but generators can handle heavier sustained loads than alternators without burning out.

C'mon man, think about it, what does your local power company call those big-azz things that "generate" the alternating current supplied to your home??

C'mon man, they call them generators, not alternators... that's because they ain't alternators, they're generators... an alternator would overload and burn out if used for that purpose. That's why inverter gen sets use inverters fed by rectified current from an alternator... because if you placed the load directly on the alternator it would overload and burn out. Just as a completely dead battery in your car can burn out an alternator... but it won't harm a generator.

*

Your auto obviously has an automatic (indirect drive) transmission, not a standard (direct drive) transmission.And on the un-exact truck comparison - your truck speed might maintain with the barely pressed throttle going down a hill, but the engine speed doesn't. It drops. My auto doesn't anyway.

Sort'a like an inverter generator places the load indirectly on the engine, and a standard generator places the load directly on the engine.

Eco-Throttle (economy) Switch is a Honda Generator feature (some others have similar)... have you read the manual on the use of it??Has a switch on it, for Eco Mode. Switch that off & it runs max speed all the time. Switch it on, it reduces speed with reduction in load.

It is only intended to be used when there is a light load, or no load on the generator... basically, when the engine is off-load‼ If the generator is connected to heavy and/or changing loads the Eco system is to be turned off.

Eco-Throttle™ Switch

The Eco-Throttle system automatically reduces engine speed when all loads are turned off or disconnected. When appliances are turned on or reconnected, the engine returns to the proper speed to power the electrical load.

If high electrical loads are connected simultaneously, turn the Eco-Throttle switch to the OFF position to reduce voltage changes.

ON – Recommended to minimize fuel consumption and further reduce noise levels when a reduced load or no load is applied to the generator.

OFF – The Eco-Throttle system does not operate. Generator operates at full speed.

With the switch in the ON position, engine speed is automatically lowered when loads are reduced, turned off, or disconnected. When appliances are turned on or reconnected, the engine returns to the proper speed to power the electrical load. In the OFF position, the Eco-Throttle system does not operate.

Appliances with large start-up power demands may not allow the engine to reach normal operating rpm when they are connected to the generator. Turn the Eco-Throttle switch to the OFF position and connect the appliance to the generator. If the engine still will not reach normal operating speed, check that the appliance does not exceed the rated load capacity of the generator.

If high electrical loads are connected simultaneously, turn the Eco-Throttle switch to the OFF position to reduce voltage changes.

The Eco-Throttle system is not effective for use with appliances or tools that require only momentary power. If the tool or appliance will be turned ON and OFF quickly, the Eco-Throttle switch should be in the OFF position.

*

NSMaple1

Addicted to ArboristSite

That reads about the same as what I said. I just didn't use as many words.

Here's the wording pasted right from my manual:

'ECONOMICAL MODE SWITCH-(G) FIG.8. When placed in the “On” position, the engine speed will be kept at idle automatically when an electrical load is disconnected and returns to proper speed to power the electrical load when reconnected. This is recommended to minimize fuel consumption during operation. Before using the electrical appliance, switch the Economical Mode switch to the “Off” position.'

Proper speed for the load. A light load isn't no load - it's still some load.

Bottom line is, the motor that is in it doesn't need to run max RPM at all times or even at those times when there is just SOME load on it. Otherwise that switch wouldn't be there. Or all of the other small engines I have wouldn't have throttle (RPM) controls.

Boots? Almost time to dig the hip waders out....

Here's the wording pasted right from my manual:

'ECONOMICAL MODE SWITCH-(G) FIG.8. When placed in the “On” position, the engine speed will be kept at idle automatically when an electrical load is disconnected and returns to proper speed to power the electrical load when reconnected. This is recommended to minimize fuel consumption during operation. Before using the electrical appliance, switch the Economical Mode switch to the “Off” position.'

Proper speed for the load. A light load isn't no load - it's still some load.

Bottom line is, the motor that is in it doesn't need to run max RPM at all times or even at those times when there is just SOME load on it. Otherwise that switch wouldn't be there. Or all of the other small engines I have wouldn't have throttle (RPM) controls.

Boots? Almost time to dig the hip waders out....

$59.99 ($0.40 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

$194.26

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$17.99

$19.99

Extendable Pole Saw Branch Trimmer Pruner Head for Tree Trimming Pruning

FENGLICNSAOMV

$23.54

$24.99

ESTWING Sure Split Wedge - 5-Pound Wood Splitting Tool with Forged Steel Construction & 1-7/8" Cutting Edge - E-5

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$225.16

OREGON 295397 Type C (All Round Yukon Chainsaw Protective Trouser, Black, Small

Express Shipping ⭐⭐⭐⭐⭐

I have no idea where you get such a silly notion... both alternators and generators produce alternating current... unless you add some form of rectification.

An alternator is not called an alternator because it produces alternating current... an alternator is called an alternator because it alternates its on/off status according to demand... something a generator cannot do.

A generator was originally called a dynamo... but its full technical name is "Alternating Current Generator".

An "alternator" is also an "Alternating Current Generator" that is also capable of automatically "alternating" its on/off status according to demand.

There are what's called D/C generators, but really, they're just A/C generators with rectifiers (just as automotive alternators use rectifiers to become D/C alternators)... remove the rectifiers and a D/C generator becomes an A/C generator (just as automotive alternators would become A/C alternators).

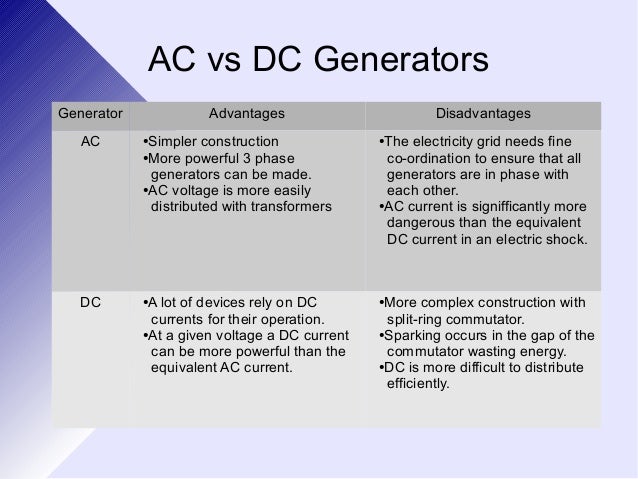

Before the common availability of rectifier diodes, multiple windings and commutator slip rings were used for rectification when D/C was preferable.

(Commutator slip rings can't work with an alternator because the winding is in the stator, not the armature.)

Both generators and alternators produce alternating current... and both can be rectified into direct current.

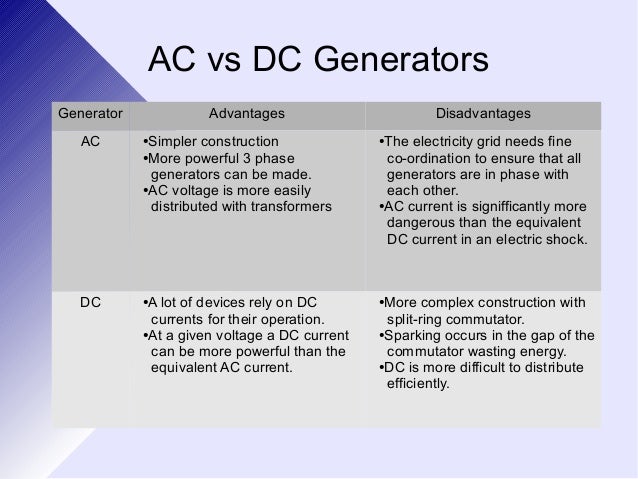

Both have advantages and disadvantages... depending on purpose. Alternators are capable of producing (on demand) higher output than generators... but generators can handle heavier sustained loads than alternators without burning out.

C'mon man, think about it, what does your local power company call those big-azz things that "generate" the alternating current supplied to your home??

C'mon man, they call them generators, not alternators... that's because they ain't alternators, they're generators... an alternator would overload and burn out if used for that purpose. That's why inverter gen sets use inverters fed by rectified current from an alternator... because if you placed the load directly on the alternator it would overload and burn out. Just as a completely dead battery in your car can burn out an alternator... but it won't harm a generator.

*

I have no idea where you get such a silly notion... both alternators and generators produce alternating current... unless you add some form of rectification.

An alternator is not called an alternator because it produces alternating current... an alternator is called an alternator because it alternates its on/off status according to demand... something a generator cannot do.

A generator was originally called a dynamo... but its full technical name is "Alternating Current Generator".

An "alternator" is also an "Alternating Current Generator" that is also capable of automatically "alternating" its on/off status according to demand.

There are what's called D/C generators, but really, they're just A/C generators with rectifiers (just as automotive alternators use rectifiers to become D/C alternators)... remove the rectifiers and a D/C generator becomes an A/C generator (just as automotive alternators would become A/C alternators).

Before the common availability of rectifier diodes, multiple windings and commutator slip rings were used for rectification when D/C was preferable.

(Commutator slip rings can't work with an alternator because the winding is in the stator, not the armature.)

Both generators and alternators produce alternating current... and both can be rectified into direct current.

Both have advantages and disadvantages... depending on purpose. Alternators are capable of producing (on demand) higher output than generators... but generators can handle heavier sustained loads than alternators without burning out.

C'mon man, think about it, what does your local power company call those big-azz things that "generate" the alternating current supplied to your home??

C'mon man, they call them generators, not alternators... that's because they ain't alternators, they're generators... an alternator would overload and burn out if used for that purpose. That's why inverter gen sets use inverters fed by rectified current from an alternator... because if you placed the load directly on the alternator it would overload and burn out. Just as a completely dead battery in your car can burn out an alternator... but it won't harm a generator.

*

An alternator is called that because the AC CURRANT it produces alternates direction depending on it's speed of rotation or the number of windings in it's stator. A DC GENERATOR's currant may be interrupted but it isn't alternated as if it was an alternator.

Oldman47

ArboristSite Guru

Well, sometimes you know what you are talking about but on automotive applications the thing that is called a generator uses a commutator to directly produce a rippled DC output to the wires it is connected to. A thing they call an alternator produces an AC output that is run through a rectifier circuit to get that same rippled DC output from the rectifier, not from the generating device. An alternator produces more power because its output winding is the stator, a large winding that is easily cooled. A generator, in automotive terms, produces its output in the rotor and thus cannot produce near as much power without overheating.I have no idea where you get such a silly notion... both alternators and generators produce alternating current... unless you add some form of rectification.

An alternator is not called an alternator because it produces alternating current... an alternator is called an alternator because it alternates its on/off status according to demand... something a generator cannot do.

A generator was originally called a dynamo... but its full technical name is "Alternating Current Generator".

An "alternator" is also an "Alternating Current Generator" that is also capable of automatically "alternating" its on/off status according to demand.

There are what's called D/C generators, but really, they're just A/C generators with rectifiers (just as automotive alternators use rectifiers to become D/C alternators)... remove the rectifiers and a D/C generator becomes an A/C generator (just as automotive alternators would become A/C alternators).

Before the common availability of rectifier diodes, multiple windings and commutator slip rings were used for rectification when D/C was preferable.

(Commutator slip rings can't work with an alternator because the winding is in the stator, not the armature.)

Both generators and alternators produce alternating current... and both can be rectified into direct current.

Both have advantages and disadvantages... depending on purpose. Alternators are capable of producing (on demand) higher output than generators... but generators can handle heavier sustained loads than alternators without burning out.

C'mon man, think about it, what does your local power company call those big-azz things that "generate" the alternating current supplied to your home??

C'mon man, they call them generators, not alternators... that's because they ain't alternators, they're generators... an alternator would overload and burn out if used for that purpose. That's why inverter gen sets use inverters fed by rectified current from an alternator... because if you placed the load directly on the alternator it would overload and burn out. Just as a completely dead battery in your car can burn out an alternator... but it won't harm a generator.

*

Power output of either a "generator" or an "alternator" is controlled by a regulator that typically controls the field winding voltage although other approaches are used for some smaller alternator circuits like the bleed device used as a regulator on some motorcycles. In that case the generated current is bled off to ground as needed to control voltage and the alternator is run wide open.

Having worked in the power industry I am well aware that generator, meaning a direct DC producing device is unique to the automotive industry. Everyone else calls any generating device a generator. The only place I have run into the word alternator is in the auto industry.

As far as the old time "dynamos", both AC and DC generators were called dynamos in the infancy of the power business and both AC and DC power were each sold by utilities at that time. GE and Westinghouse, the companies producing dynamos each had their own preference opposite to each other but when high voltage transmission became a need for long distances the AC form won out because it is easy to step up and down in voltage.

I hate hi jacking threads.. but.. talking about running air cooled engines at half throttle.. I have always been told by small engine mechanics that, the faster one runs, the cooler it is.. on guy was replacing a garden tiller engine a elderly lady had because it overheated.. he said she would never run it full throttle and it burned its self up..

I think it all depends on the engine design and how it's designed to operate.

Small 2 stroke motors tend to run better wide open.

While small 4 stroke motors run better at a slower speed.

If your running hydraulic's the hydraulic's need a slower RPM.

Diesel motors tend to run better at a slower RPM, except for a cat motor that is designed to run at a high RPM.

The reason they run cooler at higher RPM is because the fly wheel usually has fan blades that push more air at higher RPM's

Most small motors tend to not oil well or the wrong oil is used or never changed.

It all depends on the motor and it intended use.

And to add, most problems may have more to do with air/fuel mixture. Running rich or lean will make a huge difference in engine temps.

Well... now you know of a second place the term is used... alternators are used on inverter gen sets.The only place I have run into the word alternator is in the auto industry.

@Oldman47 ,

How is anything you posted different than what I have??

Here's a recap...

"An alternator produces electricity by spinning a magnetic field inside a stator winding.

A generator produces electricity by spinning an armature winding inside a magnetic field.

Alternators are capable of higher output than generators.

...both alternators and generators produce alternating current... unless you add some form of rectification.

Before the common availability of rectifier diodes, multiple windings and commutator slip rings (on generators) were used for rectification when D/C was preferable.

(Commutator slip rings can't work with an alternator because the winding is in the stator, not the armature.)

Both generators and alternators produce alternating current... and both can be rectified into direct current.

Both have advantages and disadvantages..."

*

GVS,

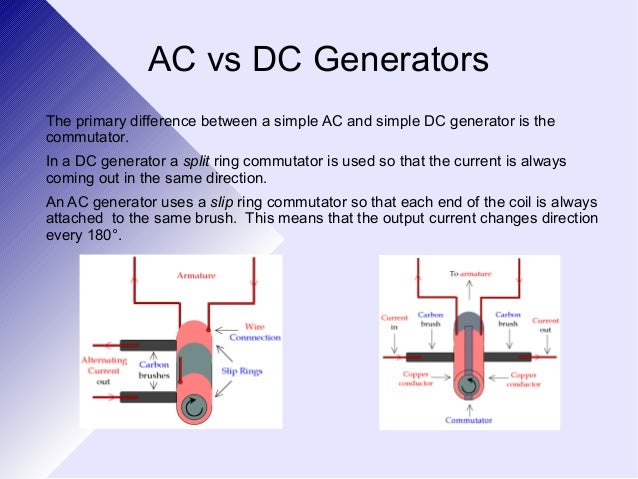

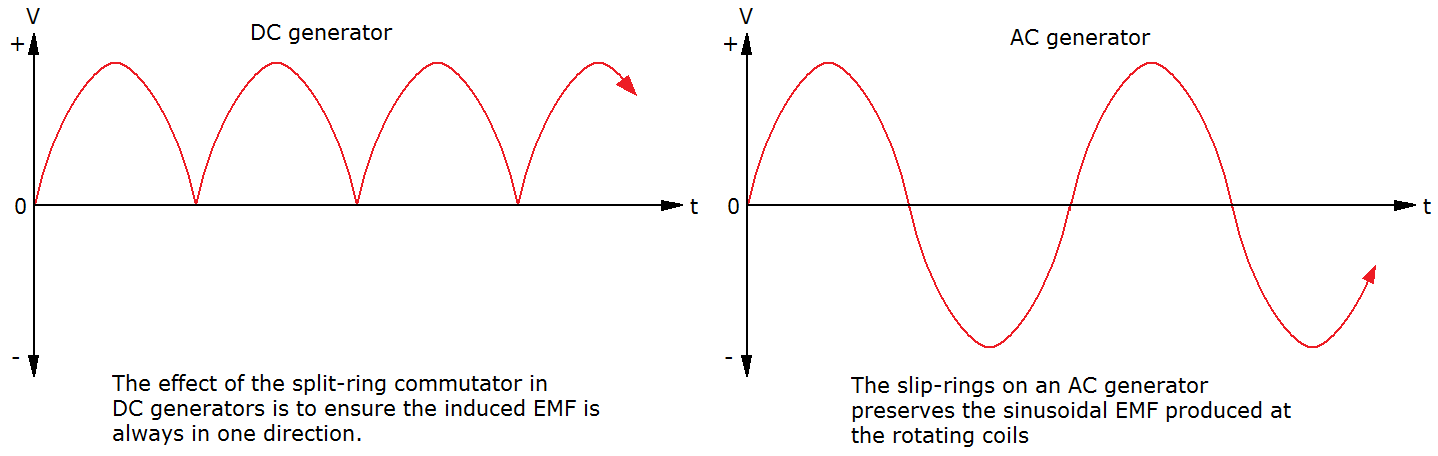

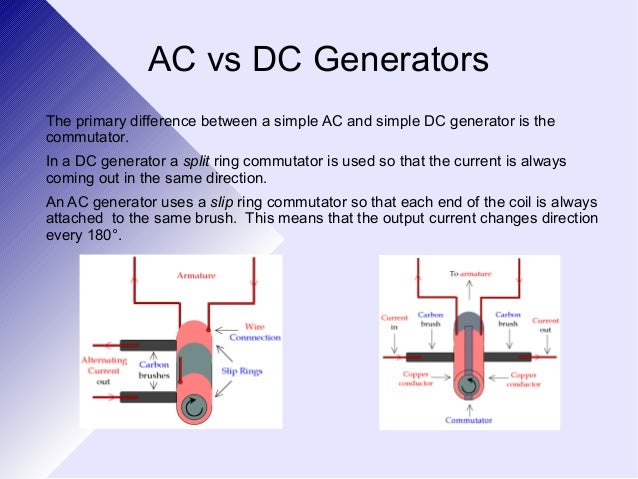

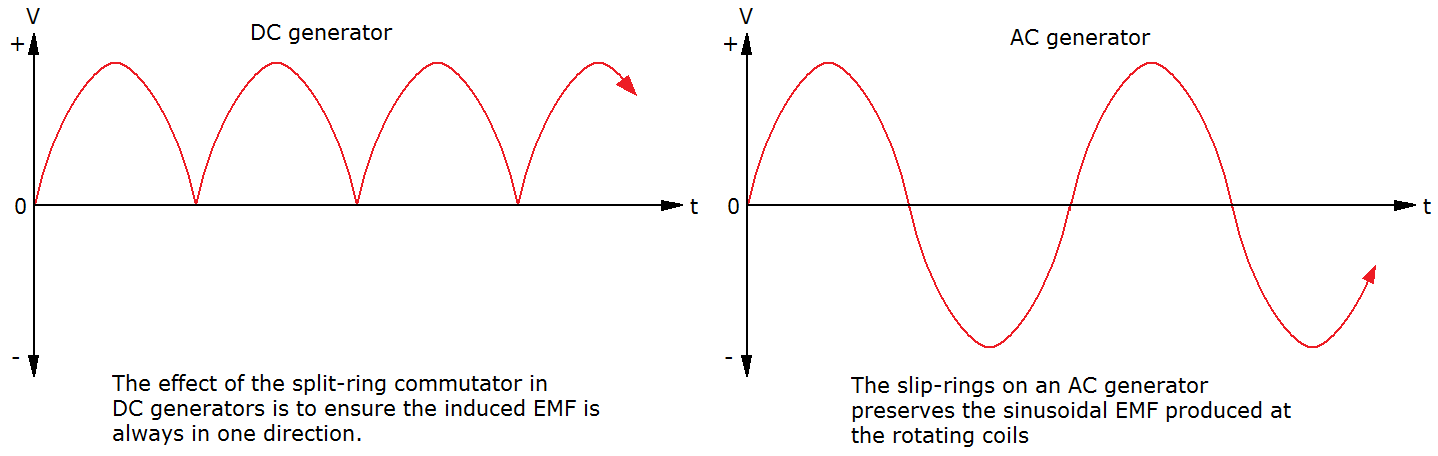

Note below these are A/C and D/C generators, not alternators... there is no stator, the electricity comes from the armature in a generator, it comes from the stator in an alternator.

Both A/C and D/C generators produce an alternating current in the armature... but the split ring commutator of the D/C generator rectifies it into a D/C output by polarizing the brushes... the current can only flow one way. This accomplishes the same thing as a rectifier bridge in an alternator... it blocks the reverse flow. It "converts" A/C current into D/C current... which is the definition of electrical rectification. It simply ain't possible to "generate" D/C current by a rotation within a magnetic field... the north/south poles can only "generate" A/C which must be rectified into D/C current in some way.

A standard (non-inverter) gen set utilizes an A/C generator... not an alternator... the difference is in the commutator.

*

Note below these are A/C and D/C generators, not alternators... there is no stator, the electricity comes from the armature in a generator, it comes from the stator in an alternator.

Both A/C and D/C generators produce an alternating current in the armature... but the split ring commutator of the D/C generator rectifies it into a D/C output by polarizing the brushes... the current can only flow one way. This accomplishes the same thing as a rectifier bridge in an alternator... it blocks the reverse flow. It "converts" A/C current into D/C current... which is the definition of electrical rectification. It simply ain't possible to "generate" D/C current by a rotation within a magnetic field... the north/south poles can only "generate" A/C which must be rectified into D/C current in some way.

A standard (non-inverter) gen set utilizes an A/C generator... not an alternator... the difference is in the commutator.

*

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 60

- Views

- 5K

Latest posts

-

-

-

-

-

-

Homelite 7-29 compression (if you got one, please post your result!)

- Latest: NorthernLonewolf

-

-