Adirondackstihl

Flyz, Fuel & Fotos

This thread make take a while.....:hmm3grin2orange:

OUCH!!

I need to finish fabricating my case splitter before I go any further.

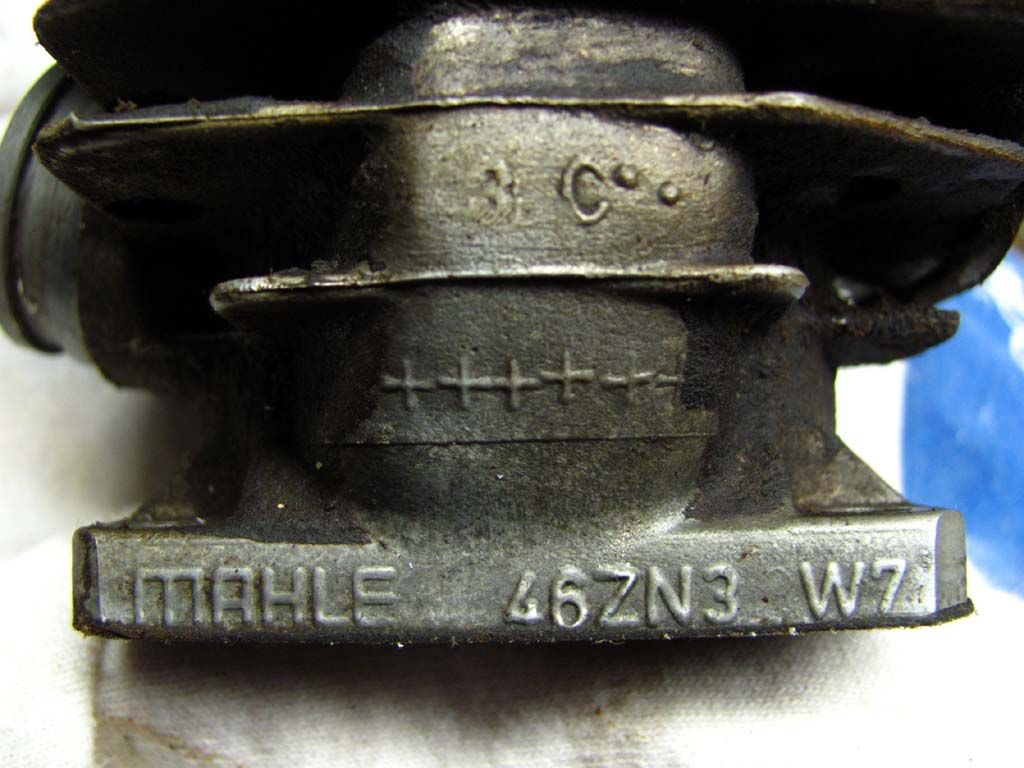

I've decided to replace the crank bearings :redface:

OUCH!!

I need to finish fabricating my case splitter before I go any further.

I've decided to replace the crank bearings :redface:

does this work

does this work