You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

McCulloch Chain Saws

- Thread starter Bruce Hopf

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

mark,

i disassembled teh rubber seat, spring and ball in teh primer, and cleaned tehm before i replaced teh o rings,,,

how is teh primer made? is it just a metal piston in a metal sleeve? if so, maybe i can cut a groove around teh piston part on my jewelers lathe, and fit a small o ring to allow it to work again,,,

i may try teh idea about steeping teh diaphram in lemon juice/warm water... nothing to lose at this point... i did soak it in brake fluid, and than in fuel mix, and it got a lot more plyable, maybe i can get it to work...

thanks for the replys.....

kb - I have tried to disassemble one, a couple of times. So far I've had no success. I really have no idea how they are put together. If anyone out there has a clue, please let us in on it.

mactodd - Do those .325 bars have a McCulloch logo on them anywhere? Post a photo or two, I may be interested as the bars that fit the Titans also fit 10 Series and 600 Series saws.

Does anyone out the story on the Titan/Double Eagle saws? Was this some sort of collaboration between McCulloch and Olympyk?

Mark

i disassembled teh rubber seat, spring and ball in teh primer, and cleaned tehm before i replaced teh o rings,,,

how is teh primer made? is it just a metal piston in a metal sleeve? if so, maybe i can cut a groove around teh piston part on my jewelers lathe, and fit a small o ring to allow it to work again,,,

i may try teh idea about steeping teh diaphram in lemon juice/warm water... nothing to lose at this point... i did soak it in brake fluid, and than in fuel mix, and it got a lot more plyable, maybe i can get it to work...

thanks for the replys.....

kb - I have tried to disassemble one, a couple of times. So far I've had no success. I really have no idea how they are put together. If anyone out there has a clue, please let us in on it.

mactodd - Do those .325 bars have a McCulloch logo on them anywhere? Post a photo or two, I may be interested as the bars that fit the Titans also fit 10 Series and 600 Series saws.

Does anyone out the story on the Titan/Double Eagle saws? Was this some sort of collaboration between McCulloch and Olympyk?

Mark

briantutt

Addicted to ArboristSite

pm 650

After I fixed the rewind, leaky oil tank, chain brake, switch plate, new air filter my PM650 fired right up and ran nicely. After a couple month sit I pull it out to use it and now it fires up, runs after the choke and then acts really cold blooded. If I ease into the throttle it starts to rev up then dies. If I hard pull the throttle it just dies...:bang:

After I fixed the rewind, leaky oil tank, chain brake, switch plate, new air filter my PM650 fired right up and ran nicely. After a couple month sit I pull it out to use it and now it fires up, runs after the choke and then acts really cold blooded. If I ease into the throttle it starts to rev up then dies. If I hard pull the throttle it just dies...:bang:

mactodd

ArboristSite Operative

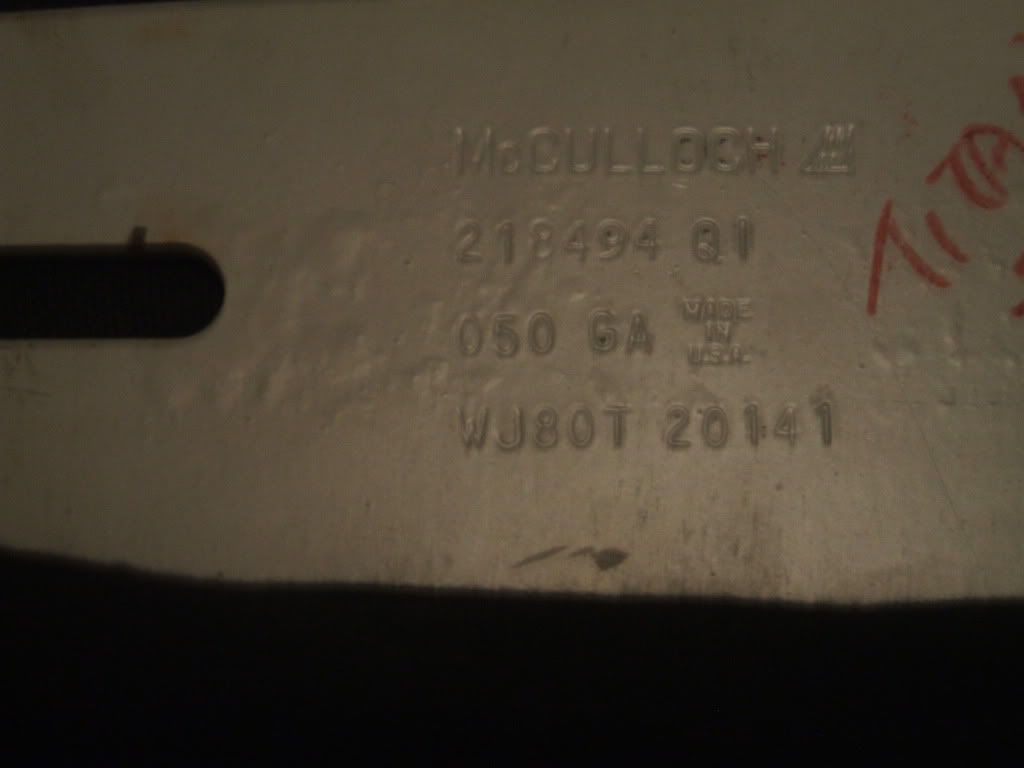

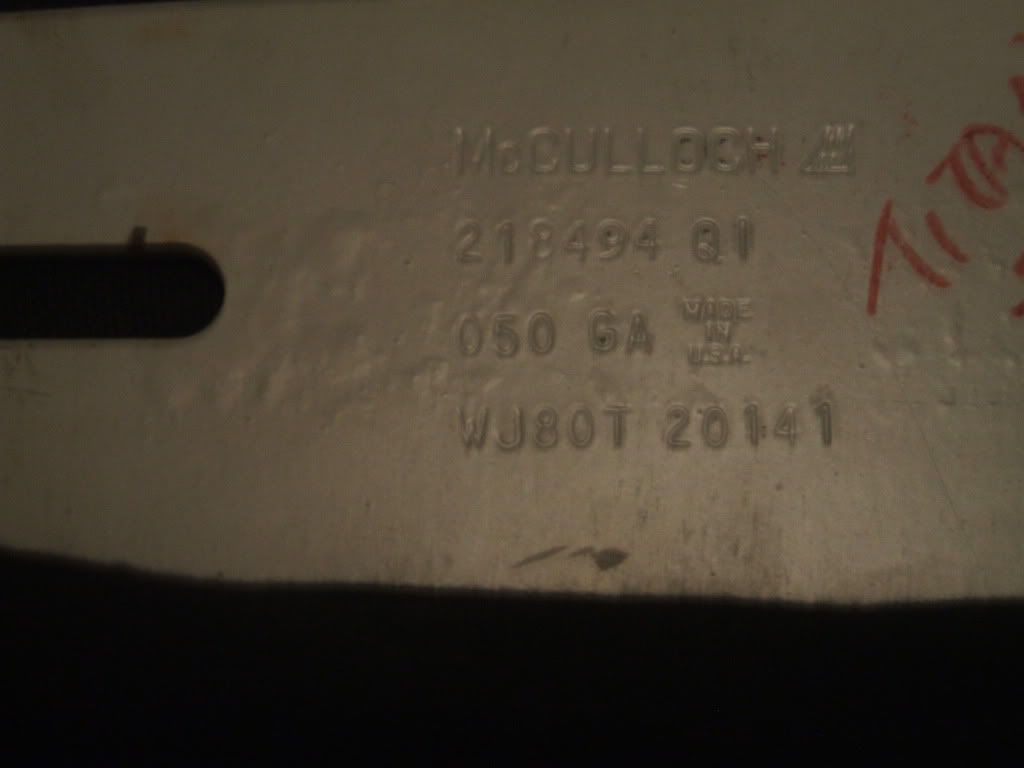

Yep, Mac branded

What tells me the DL count?

Yes, I guess they will fit a Mac 10! Just need to get a .325 rim. I got a use for them after all! :greenchainsaw:

Just need to get a .325 rim. I got a use for them after all! :greenchainsaw:

19" overall length, .050 guage.

I got 6 of 'em, and I'll use 2. Like I said, cosmetically challenged-- rust stains, chipped paint, rust bubbles under the paint on a couple. More for work than show. I'll let them go for what I paid: $10 ea. plus shipping. These things are heavy-- 3+ pounds.

What tells me the DL count?

Yes, I guess they will fit a Mac 10!

Just need to get a .325 rim. I got a use for them after all! :greenchainsaw:

Just need to get a .325 rim. I got a use for them after all! :greenchainsaw:

19" overall length, .050 guage.

I got 6 of 'em, and I'll use 2. Like I said, cosmetically challenged-- rust stains, chipped paint, rust bubbles under the paint on a couple. More for work than show. I'll let them go for what I paid: $10 ea. plus shipping. These things are heavy-- 3+ pounds.

Last edited:

This is not a saw, but it is a MAC and ...

if your truck breaks down or gas gets too high. http://cgi.ebay.com/Older-Motor-Mot...403?pt=LH_DefaultDomain_0&hash=item27b5828cf3 I thought some some of you might like to add this to your collection. Ron

if your truck breaks down or gas gets too high. http://cgi.ebay.com/Older-Motor-Mot...403?pt=LH_DefaultDomain_0&hash=item27b5828cf3 I thought some some of you might like to add this to your collection. Ron

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$56.99 ($0.38 / Foot)

$69.79 ($0.47 / Foot)

Arborist Rigging Rope 1/2 in x 150 Ft Blue Bull Rope Polyester Braided Arborist Rope 1/2 inch 48 Strands 150 Feet for Various Outdoor Applications Construction Climbing Swing Sailing

Glfcai store

$59.99 ($0.40 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$56.99 ($0.38 / Foot)

$59.99 ($0.40 / Foot)

Double Braid Arborist Rope Orange(1/2 in x 150 ft) Arborist Rigging Polyester Rope - 48 Strand Rope Swing for Tree Bull Rope for Outdoor, Climbing, Swing, Sailing

Cosirulnta Shop

$19.99 ($3.33 / Count)

Firewood Log Splitter 45mm+32mm + 4 Handles (Square + Round + Hex Shank + Small Hex) Wood Log Splitter Easy Splitter Detachable Drill Bit Heavy Duty Electric Drills Screw Cone Driver Removable

JianShiMoQinDianZiShangWuYouXianGongSi

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

$39.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$14.99

$17.99

Fiskars Pole Saw Blade Replacement for Fiskars Pruning Saws and Tree Pruners, 15" Blade with Woodzig Chainsaw-Style Tooth Design

AMZ South Supply

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

Ron, that engine went on one of these

Really. I thought it was something from the fifties. It shows you how much I know. Ron

lawnmowertech37

Addicted to ArboristSite

Mark H whats it going to take for these mac parts to start finding homes ?

Eccentric

Mister Wizard

ecc - Ike Hoff posted a very interesting message about steeping parts in a mixture of warm water and lemon juice to soften and free up tough old stuck diaphragms. He says he never has to replace stiff old diaphragms if this trick is applied.

Mark

It's worth a shot Mark. You may notice a 'fresh lemon scent' coming from that McCulloch 77 when you first open the box!

Has anyone come up with a good alternative/substitution for the rubber seals that the choke, throttle, and oil rods pass through in the rear of the handle/carb box assembly? Gonna have to scare up some NOS pieces, or come up with an acceptable substitute for the 790's at some point...

It's worth a shot Mark. You may notice a 'fresh lemon scent' coming from that McCulloch 77 when you first open the box!

Has anyone come up with a good alternative/substitution for the rubber seals that the choke, throttle, and oil rods pass through in the rear of the handle/carb box assembly? Gonna have to scare up some NOS pieces, or come up with an acceptable substitute for the 790's at some point...

I love fresh lemon...What can ya send me?

mac 250 flatback...

mark,,,

i've gone thru the carb as directed by your tutorial, and i have a couple questions, the pics may help explain tehm,,,

1st, the lever is set level, with the carb base, without a gasket, whether teh diaphram is the original with teh flat plate, or the replacement, with teh button, correct?

2nd, the gasket sandwich for the fuel pump has teh two pump tabs thru the slots, so tehy lie flat against teh carb body, correct...

i am using the original diaphram & fuel pump,, and teh pump sandwich is stapled together, so it was original installed like that... i think you mentioned, you were not able to get the primer to work with a new (replacement) fuel pump assembly, without putting teh pump tabs against teh carb, without a gasket... correct?

i have teh diaphram steeping in teh lemon water brew as we speak, so we'll try it again,,,

thanks for you help,,,

john

mark,,,

i've gone thru the carb as directed by your tutorial, and i have a couple questions, the pics may help explain tehm,,,

1st, the lever is set level, with the carb base, without a gasket, whether teh diaphram is the original with teh flat plate, or the replacement, with teh button, correct?

2nd, the gasket sandwich for the fuel pump has teh two pump tabs thru the slots, so tehy lie flat against teh carb body, correct...

i am using the original diaphram & fuel pump,, and teh pump sandwich is stapled together, so it was original installed like that... i think you mentioned, you were not able to get the primer to work with a new (replacement) fuel pump assembly, without putting teh pump tabs against teh carb, without a gasket... correct?

i have teh diaphram steeping in teh lemon water brew as we speak, so we'll try it again,,,

thanks for you help,,,

john

Eccentric

Mister Wizard

I love fresh lemon...What can ya send me?

I'll sqeeze a bunch of lemons over five cases of Corona and send them to you in trade for your Homie 2000. Gotta keep at it...:biggrinbounce2:

kb - Interesting point on the metering lever height. I have some old metering diaphragms with the "button" and other without it. I never gave it much thought and always set the metering lever flush or just slightly proud of the body. That might explain why my 440 with the Sugar Creek kit is a bit hard to start at times. I guess I would stick with level with the top with a button, and maybe an added .020-0.030" with the flat plate.

My very limited experience indicates the primer does not work effectively if the flaps of the fuel pump diaphragm are not held directly against the body of the carburetor. I probably need to repeat the test with a couple of different set ups and a known good primer and with the check valve in good shape as well. Since yours have the flaps in the proper position it should work as well as can be expected.

I did prove to myself anyway that the fuel pump will work just fine no matter how you arrange the diaphragm and gaskets if you give it a shot of prime directly down the throat of the carburetor, once it fires and runs a bit the fuel pump pumps.

Mark

My very limited experience indicates the primer does not work effectively if the flaps of the fuel pump diaphragm are not held directly against the body of the carburetor. I probably need to repeat the test with a couple of different set ups and a known good primer and with the check valve in good shape as well. Since yours have the flaps in the proper position it should work as well as can be expected.

I did prove to myself anyway that the fuel pump will work just fine no matter how you arrange the diaphragm and gaskets if you give it a shot of prime directly down the throat of the carburetor, once it fires and runs a bit the fuel pump pumps.

Mark

mac 250 flatback...

mark,

thanks again for your reply,,, the lemon water soak really did loosen up teh diaphram, to teh point it flexes like a new one... so, i'm thinking there is something else wrong here,,, when i 1st took teh carb apart, it was clean as whistle inside, like teh rest of the saw, and i do remember, after first reading your carb tutorial, when i checked teh lever, it was much higher than level with teh carb body,,, i doubt anyone was in there since it was new, so its as good a place as any to start,,, i posted in another thread that i can't find an ipl for this saw with a flatback carb in it, but i would like to find original mac carb setup specs, as this thing is not easy to take teh carb in and out of,,,i already got rid of teh original lock nuts that hold teh carb on, and there is no use putting teh primer rod back in, as it isn't working... i went thru it again, and pumped it repeatedly with teh carb out of teh saw, but can't get it to prime at all...

i enjoy a good challange, and this carb may be it!!!!! teh saw starts instantly on a little fuel poured in it. the fuel lines are new and clear, so its not far from working...

keep in touch, if you have any other tips, this is my 1st mac,,,, maybe my last!!!!!!!!!

john

mark,

thanks again for your reply,,, the lemon water soak really did loosen up teh diaphram, to teh point it flexes like a new one... so, i'm thinking there is something else wrong here,,, when i 1st took teh carb apart, it was clean as whistle inside, like teh rest of the saw, and i do remember, after first reading your carb tutorial, when i checked teh lever, it was much higher than level with teh carb body,,, i doubt anyone was in there since it was new, so its as good a place as any to start,,, i posted in another thread that i can't find an ipl for this saw with a flatback carb in it, but i would like to find original mac carb setup specs, as this thing is not easy to take teh carb in and out of,,,i already got rid of teh original lock nuts that hold teh carb on, and there is no use putting teh primer rod back in, as it isn't working... i went thru it again, and pumped it repeatedly with teh carb out of teh saw, but can't get it to prime at all...

i enjoy a good challange, and this carb may be it!!!!! teh saw starts instantly on a little fuel poured in it. the fuel lines are new and clear, so its not far from working...

keep in touch, if you have any other tips, this is my 1st mac,,,, maybe my last!!!!!!!!!

john

mac 250 flatback...

i forgot to ask in teh last post,,, what do you think of adding a "priming bubble", like teh newer small engines have? taht would let you see it was priming, and keep from taking teh saw apart to prime it...

i forgot to ask in teh last post,,, what do you think of adding a "priming bubble", like teh newer small engines have? taht would let you see it was priming, and keep from taking teh saw apart to prime it...

I have IPL's for the 250 showing three different carburetor types, McCulloch with primer, McCulloch with choke (Super 250), and Tillotson HL. Send me your e-mail address if you'd like to see these IPL's.

The external bulb type primers are intended to pull fuel to/through the carburetor, whereas the primer on the McCulloch carburetors are designed to pump fuel directly into the intake. I suppose it might be possible to rig a set up to pump fuel to the carburetor with the bulb type primer, but if the primer on the carburetor is not working you still won't be charging the intake with fuel for the cold start.

Mark

The external bulb type primers are intended to pull fuel to/through the carburetor, whereas the primer on the McCulloch carburetors are designed to pump fuel directly into the intake. I suppose it might be possible to rig a set up to pump fuel to the carburetor with the bulb type primer, but if the primer on the carburetor is not working you still won't be charging the intake with fuel for the cold start.

Mark

mac 250 flatback...

well, as you guys already knew & i found out, mark h is teh mac man,,,

i just got teh 250 running, with the flatback,,,, primer still doesn't prime, but that seems to be teh nature of the beast...

here are a few settings i used to get this saw going again...

1st,, i soaked teh diapham in teh lemon/hot water solution for about an hour, this was the original diaphram, not a replacement...

2,, i set teh lever approx 1/16" above teh carb base, as apposed to setting it level, as diaphams with the button or nib on them...

3,, set the L needle about one turn open...

4,, set teh H needle 3/4 turn open..

i primed it with a little fuel thru the carb, (as mark suggested), and it fired on teh 1st compression stroke and kept running,, i fattened up the L a little, until it didn't stumble on acceleration,,, i need a b/c before i can put it in wood and fine tune the H.... but it sounds really good, and responsive,,, idle sounds like a harley!!!

again,, thanks to mark h., chris j,, and every one else who helped me with this project,, didn't think it would be running this quickly, i didn't have it a week yet,,, you guys are great!!!!!!

john

well, as you guys already knew & i found out, mark h is teh mac man,,,

i just got teh 250 running, with the flatback,,,, primer still doesn't prime, but that seems to be teh nature of the beast...

here are a few settings i used to get this saw going again...

1st,, i soaked teh diapham in teh lemon/hot water solution for about an hour, this was the original diaphram, not a replacement...

2,, i set teh lever approx 1/16" above teh carb base, as apposed to setting it level, as diaphams with the button or nib on them...

3,, set the L needle about one turn open...

4,, set teh H needle 3/4 turn open..

i primed it with a little fuel thru the carb, (as mark suggested), and it fired on teh 1st compression stroke and kept running,, i fattened up the L a little, until it didn't stumble on acceleration,,, i need a b/c before i can put it in wood and fine tune the H.... but it sounds really good, and responsive,,, idle sounds like a harley!!!

again,, thanks to mark h., chris j,, and every one else who helped me with this project,, didn't think it would be running this quickly, i didn't have it a week yet,,, you guys are great!!!!!!

john

b/c for a mac 250...

now that its running, i need a b/c for it,,, acres site calls for .404 mac pintail chain,, but doesn't list the bar type,, i've read where guys are using 3/8 bars & chain on these saws, whats the advantage of each?? what bar pattern will fit the saw? will anything besides the old original mac bars work?

thanks in advance....

now that its running, i need a b/c for it,,, acres site calls for .404 mac pintail chain,, but doesn't list the bar type,, i've read where guys are using 3/8 bars & chain on these saws, whats the advantage of each?? what bar pattern will fit the saw? will anything besides the old original mac bars work?

thanks in advance....

Danno

ArboristSite Operative

now that its running, i need a b/c for it,,, acres site calls for .404 mac pintail chain,, but doesn't list the bar type,, i've read where guys are using 3/8 bars & chain on these saws, whats the advantage of each?? what bar pattern will fit the saw? will anything besides the old original mac bars work?

thanks in advance....

I sent a couple of emails off about my Mac15 to baileysonline and the conclusion appeared to be that .404 .063 chain will work and the bar would be very similar to a husky bar, but would require minor modification of (memory failing here) either the mounting holes or the adjustment holes or something of that nature.

Interested to see what you go with, as I'd like to get a bigger b/c combo.