The SP81 lives - carb question tho

Well I managed to get the old corroded SP81 I picked up on Sunday going with minimal effort. Truth be told it took longer to file the chain than get it running.

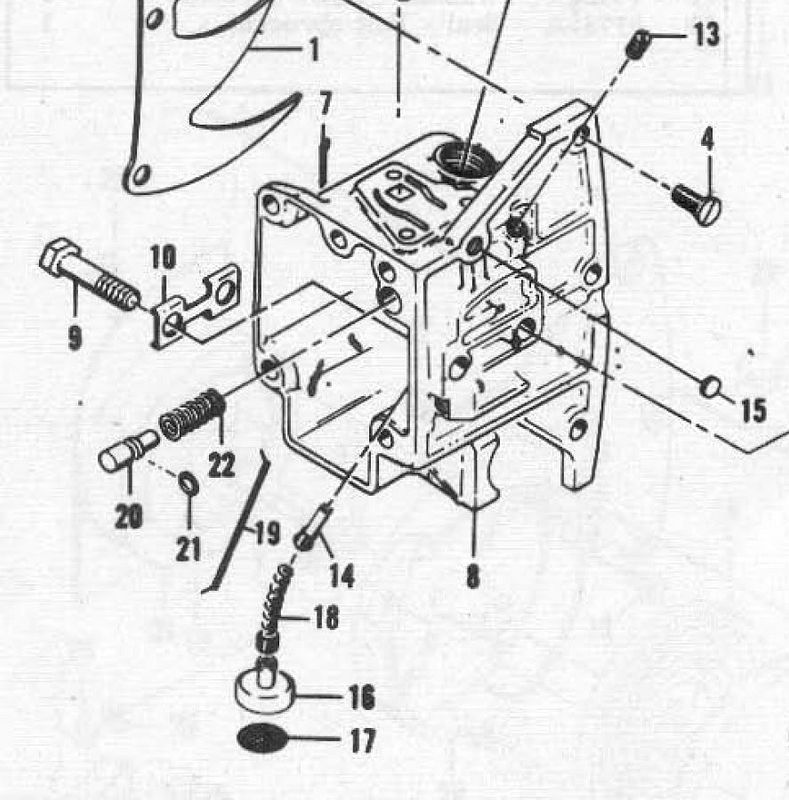

The fuel line is surprisingly just as supple as new; thank heavens because they're not easy to find OR get to seal at the carb box / fuel tank divider, at least based on my 10-10 experience. This thing looks mostly the same. The carb was also still completely serviceable, though the metering diaphragm is ever so slightly distorted and should still be replaced. Here's my Mac carb question - both the 10-10's carb and this one had been built with BOTH the rubber and the stiffer "plastic" (not sure what it's made of) pump/valve diaphragms installed, one on top of the other; are they supposed to be like this, or is it just coincidence that both guys thought they needed to use all the parts in the rebuild kit bag?. I rebuilt this one with only the rubber diaphragm, and it seems to be just fine without the other one.

I primed it with some fuel down the carb and it fired right up. At first it wouldn't pull fuel and would quickly die, but after three or four tries it finally loosened up and I was able to tune it. It still intermittently runs rich at WOT (though cuts just the same under load), but seems to hold an idle and accelerate OK, so I'm hoping a new metering diaphragm will even things out.

With that in mind though, the piston and cylinder didn't look too pretty through the intake port when I had the carb off - there are a couple score lines on the intake side of the piston, and what I could see of the exhaust side cylinder wall was worse. One of the muffler bolts was rusted too badly to remove without a good soak in some penetrant first - I ended up spinning one of my allen wrenches off on it, it was stuck so tight. I still may end up drilling/cutting the head off just to be able to remove the muffler and then take care of the bolt stud with a pair of vise grips or something.

Even still, the thing makes really good compression. It felt pretty strong even cold, but once I got it hot, I could hold it up by the starter rope for a good 10 seconds before it dropped a turn. I didn't have much to test it out in - only a chunk of ~9" Pine. It cut pretty well, even considering that I took the cutters back a fair bit but didn't bother with the rakers. They looked like they've never been touched; once I get the FOP to them it should bite a fair bit better. One thing I can say is that this saw is NOT good for noodling! There is hardly any clearance around the clutch/sprocket and it packs tight after just a few inches of cutting. The oiler took a while to clear out and get going; the manual plunger was a bit sticky right off the bat too but freed up after some use and seems to work.

Overall I'm pretty impressed with it given the condition of the topend. I don't think I'd put it above a 181SE (feel free to

!) though a new topend just might do it. It's surprisingly smooth on the vibes and fairly quiet, too. I do still need to give this thing a full teardown, so I'll work on the piston and cylinder as much as I can then. My friend MIGHT have a piston for this thing, but it may not be much better. I can't really complain though with how it's performing as-is; not worth sinking a bunch of money into finding a piston at any rate.

I

would make a video with this saw, but not until I get the corrosion taken care of.

!) though a new topend just might do it. It's surprisingly smooth on the vibes and fairly quiet, too. I do still need to give this thing a full teardown, so I'll work on the piston and cylinder as much as I can then. My friend MIGHT have a piston for this thing, but it may not be much better. I can't really complain though with how it's performing as-is; not worth sinking a bunch of money into finding a piston at any rate.

!) though a new topend just might do it. It's surprisingly smooth on the vibes and fairly quiet, too. I do still need to give this thing a full teardown, so I'll work on the piston and cylinder as much as I can then. My friend MIGHT have a piston for this thing, but it may not be much better. I can't really complain though with how it's performing as-is; not worth sinking a bunch of money into finding a piston at any rate.